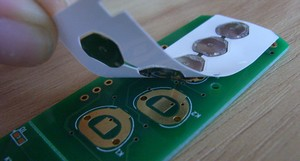

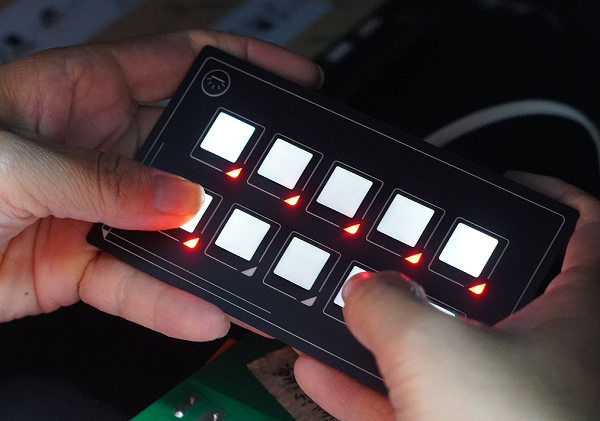

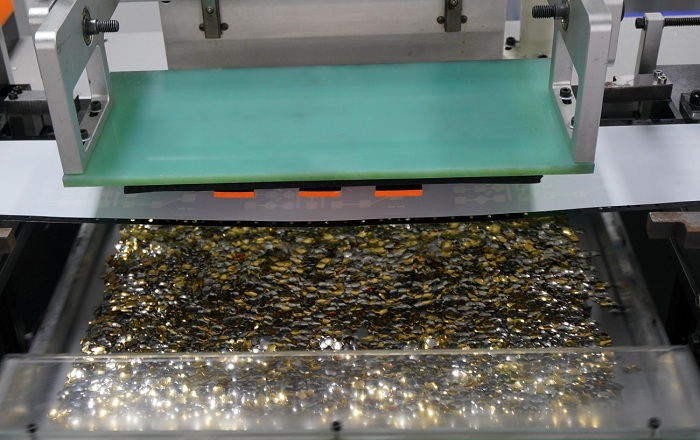

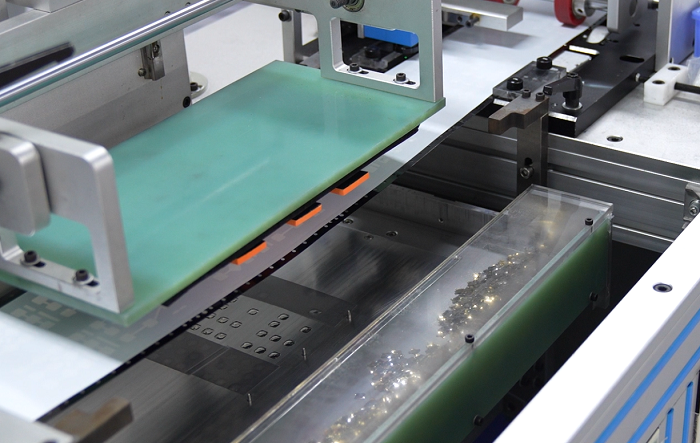

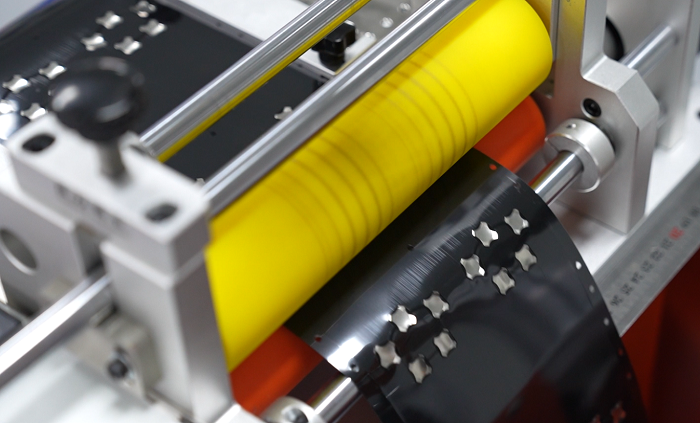

The metal dome is mainly installed in the Poly dome membrane switch as a command control device. Poly dome membrane switch, also called panel button, is an electronic switch that integrates panel and switch functions. Metal domes need to be used in a dustproof and waterproof environment to prevent the external environment from affecting the service life of the metal dome. The metal dome is in the Poly dome membrane switch and is combined with the lines in the Poly dome membrane switch to conduct electricity and transmit instructions by pressing.

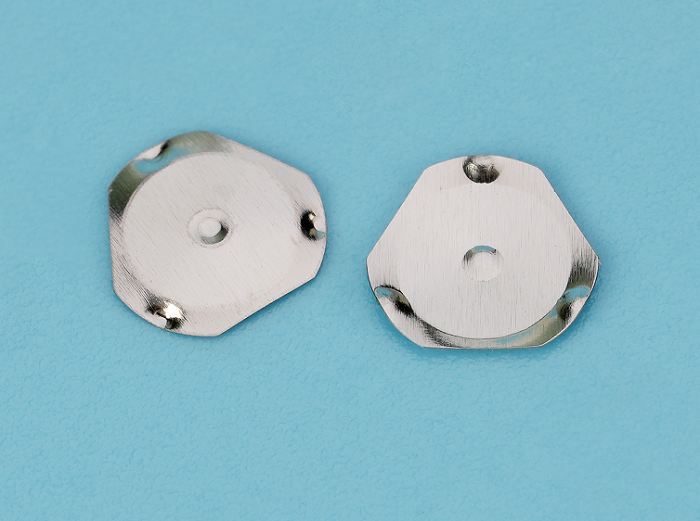

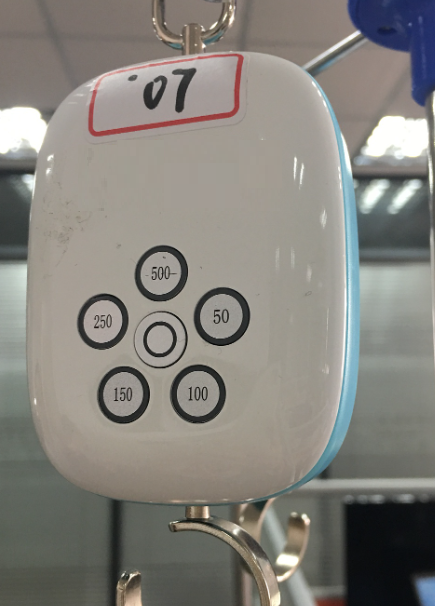

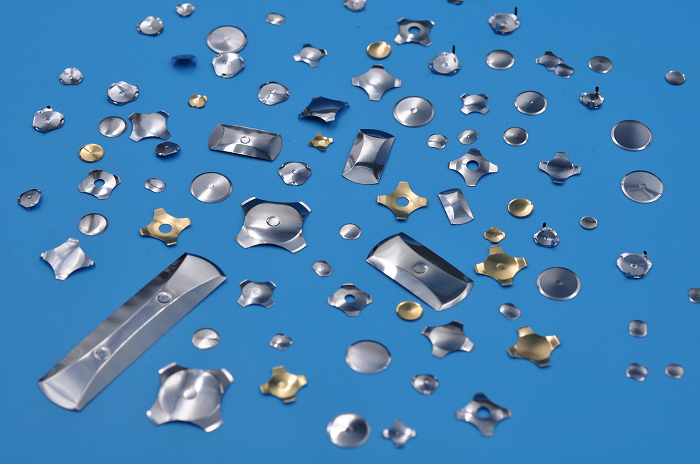

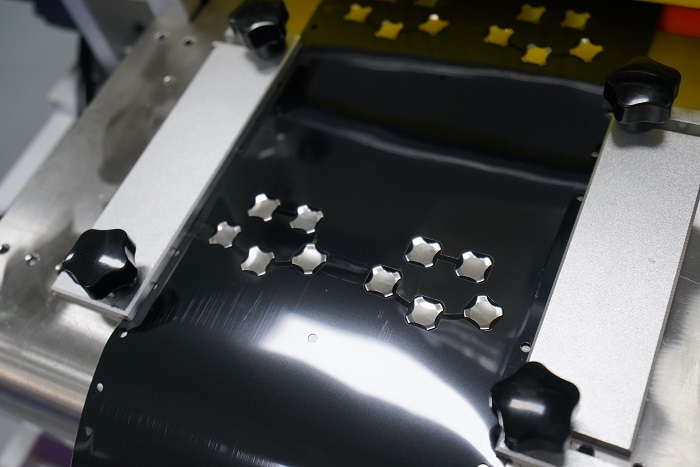

There are many different types of metal domes so what are the differences between them? The main shapes of metal domes are: round metal domes, triangles, rectangles, and ovals. Among them, metal domes are divided into those with feet and without feet. The selection of metal domes depends on the design and production of domes according to different products. The environments and functions of different metal domes are different. The metal dome installed in the Poly dome membrane switch can enhance the touch and conductivity. When the panel is pressed, it also acts on the metal dome and conducts lines through the metal dome, providing a stable and consistent mechanism for electronic products. operate.

Advantages of metal domes in use

Compact and lightweight: The metal dome has the advantage of being compact and lightweight in use, saving space for product production, and is very easy to carry and disassemble during installation.

Sealing: The metal dome adopts unique technology in the Poly dome membrane switch, which can make the metal dome waterproof, oil-proof, anti-pollution, anti-static interference and other functions in the Poly dome membrane switch without affecting the function of the metal dome. use.

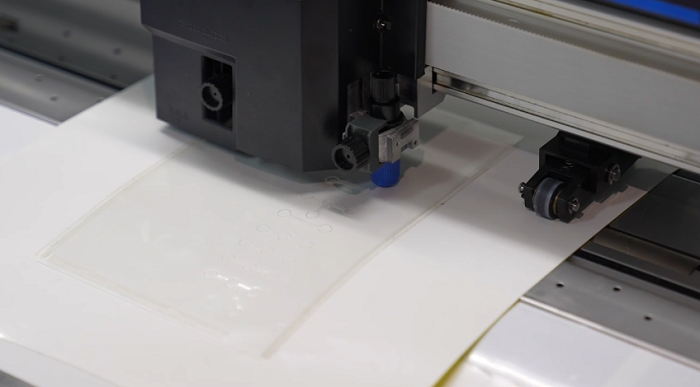

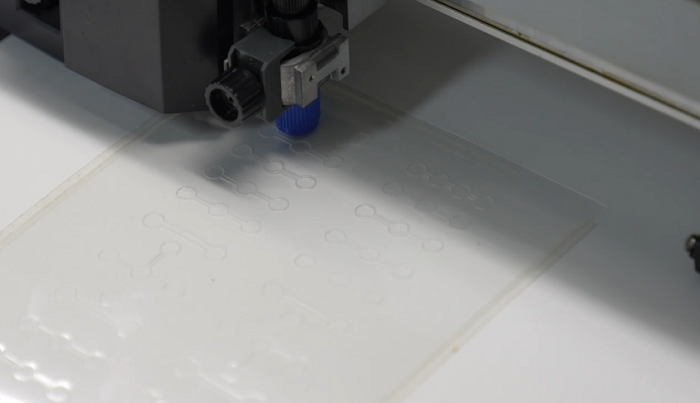

Excellent conductivity: The circuit of the metal dome in the Poly dome membrane switch can be printed with carbon paste, silver paste, copper platinum, etc., and the conductive layer can be folded at will; and the resistance can be controlled at any resistance you want, and the metal dome passes Nickel plating can increase the conductive properties of use.

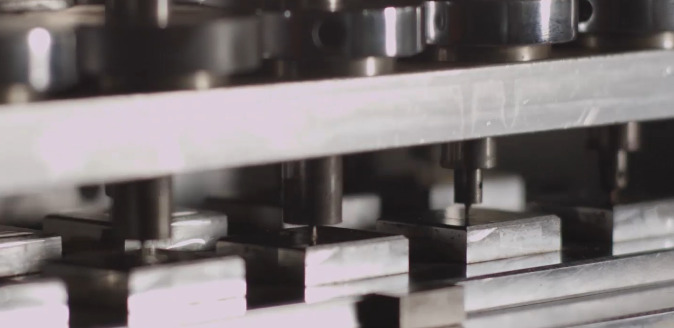

Low cost: Ordinary metal domes are low cost and highly cost-effective. Mass production, metal domes have stable functions and more favorable prices. Compared with a multi-functional electronic original device product, it has a price advantage.

Long service life: The metal dome is made of stainless steel raw materials, which has good insulation, heat resistance, bending resistance and high resilience; through life testing, the metal dome can be used 5 million times. The metal dome can have the best life span in a good environment, and the machine can run stably during use.

The metal dome has a closed space in the Poly dome membrane switch which can reduce dust and waterproof, making the performance of the metal dome more stable.

Best Technology has more than ten years of experience in manufacturing metal domes, with customers all over the world, and has rich experience in producing metal domes that fit the product. The metal dome produced has stable performance in application, long service life and high cost performance. If you have any questions about metal domes, you can send us an email to: sales@metal-domes.com and we will answer you as soon as possible!