A keyboard metal dome refers to a small, rounded, metallic component used in dome switch keyboards. These metal domes are typically made from stainless steel and are crucial for the operation of the keyboard.

What is a Dome Switch Keypad?

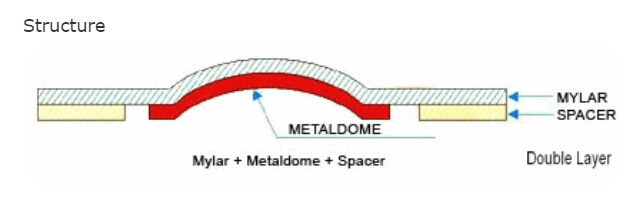

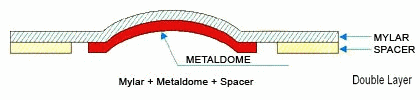

A dome switch keypad is a type of keyboard that uses metal domes to complete an electrical circuit when a key is pressed. These keyboards are popular due to their balance between comfort, reliability, and cost-efficiency. The metal domes sit beneath the rubber or silicone layer of the keys, providing a tactile response when pressed. This is why they are widely used in various applications, including computers, remote controls, and other input devices.

The metal dome itself acts as the bridge between the keypad and the circuit board. It gives a distinct clicking sound and tactile feedback when a button is pressed. This ensures that the user knows the input has been registered. Compared to other types of switches, dome switch keypads offer good balance of tactile feedback and performance.

Why Use Keypad Metal Dome?

Keypad metal domes are crucial components that significantly enhance the functionality of the keypad. They provide a tactile response, which is essential for people who rely on the sense of touch to confirm a keypress.

When you press a key on a dome switch keyboard, the keycap pushes down on the metal dome, which in turn makes contact with the underlying circuit board, completing the electrical circuit. This action sends a signal to the computer or device, registering the keypress.

Using metal domes has multiple benefits:

- Tactile Feedback: Metal domes provide a tactile click when pressed, offering feedback to the user that the keypress has been registered.

- Durability: Metal domes are designed to withstand millions of keypresses, making them a popular choice for high-usage environments.

- Responsive Feel: These switches provide a snappy, responsive feel, often favored in membrane keyboards and other types of input devices.

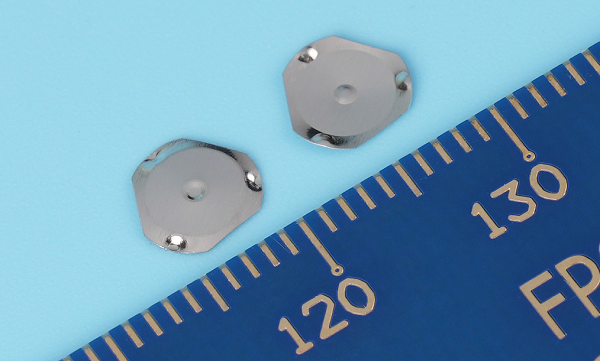

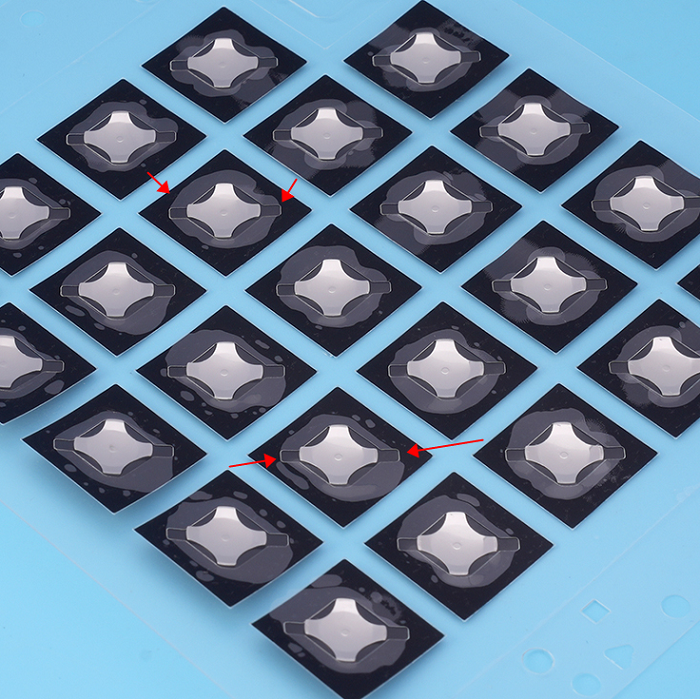

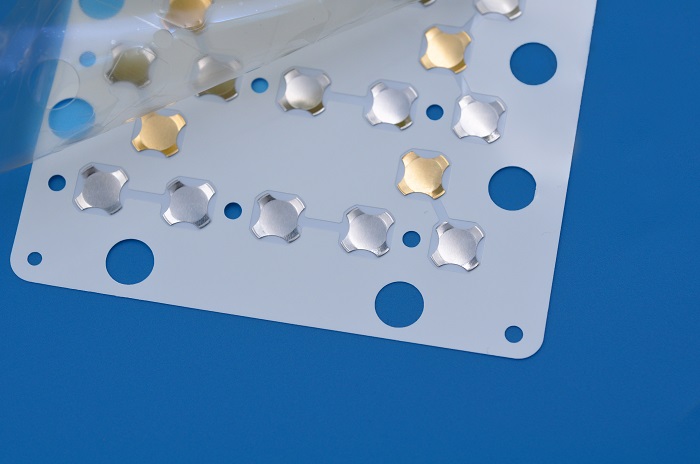

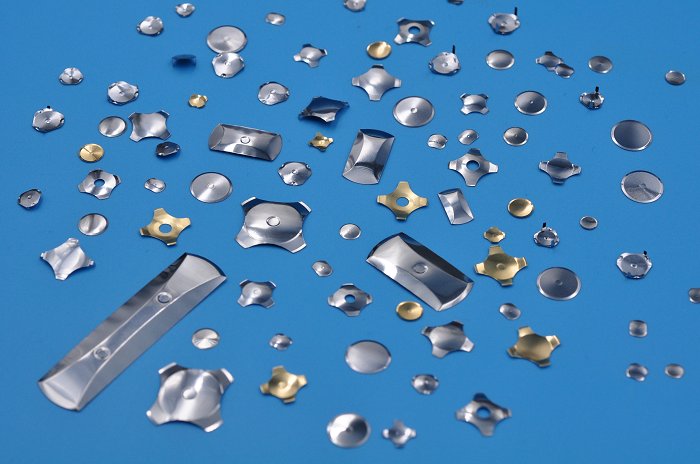

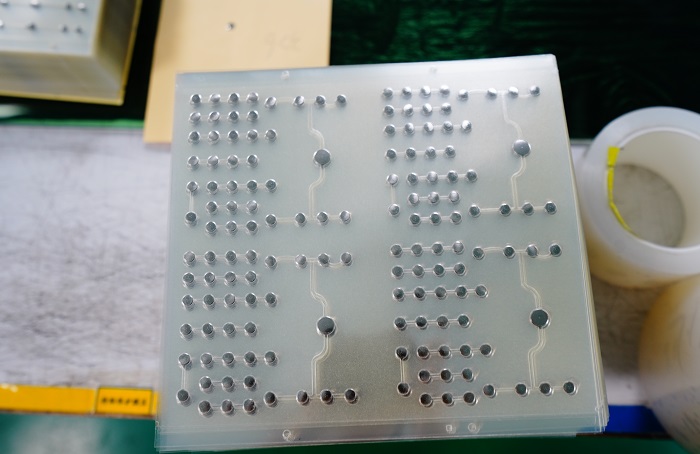

Metal Dome Options

- Dome plating: can be plated in other metals such as nickel, silver or gold

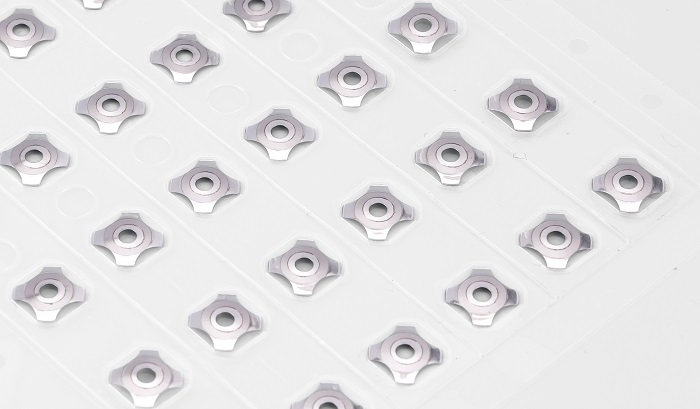

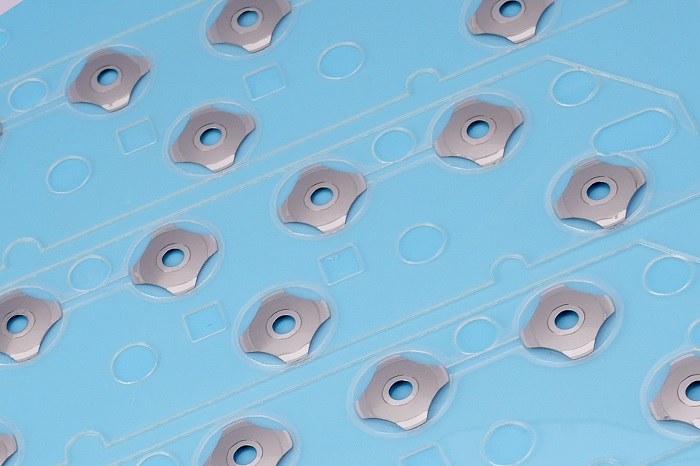

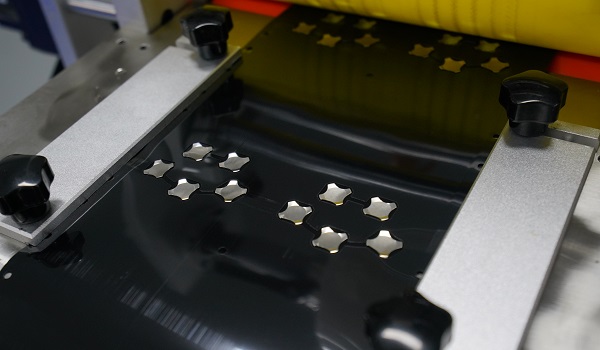

- Dome shapes: four-leg, triangle, round/circle, oblong

- Dome sizes: standard sizes are 6mm, 7mm, 8.5mm, 10mm, 12mm, 14mm, 16mm and customized option

- Dome forces: standard forces range from 85g to 700g

- Other options: dimpled, hole in center (for backlighting key), double-contact closure domes.

What is Dome Actuation Forces?

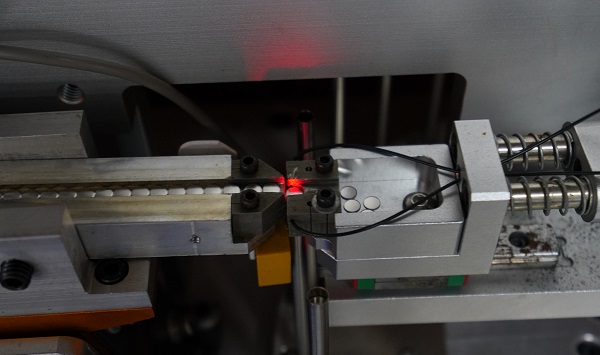

The actuation force of a dome refers to the amount of pressure required to collapse the dome and complete the circuit. This force is a critical factor in determining how a keypad feels to the user. Actuation force is usually measured in grams and can vary depending on the design and material of the dome.

For example, a lighter actuation force results in a softer press, while a heavier force provides more resistance and a firmer feel. Choosing the right actuation force is important because it affects the overall user experience. A force that is too light might lead to accidental presses, while a force that is too heavy could cause fatigue over extended use.

What is the Most Commonly Used Force Range for Metal Dome?

The most commonly used actuation force range for metal domes falls between 100 and 400 grams. This range provides a good balance between comfort and reliability for most users. Lighter forces, around 100 grams, are often preferred in devices that require quick and frequent inputs, like remote controls. On the other hand, heavier forces, up to 400 grams, are used in applications where preventing accidental presses is critical, such as in industrial machinery controls.

Here is a force range for each type of snap domes:

| Metal Domes | Diameter | Force |

| Round Dome | 2.5-6mm | 100-200g |

| >7mm | 140-300g | |

| Triangle Dome | 4-12mm | 100-800g |

| Four-leg Dome | 5-7mm | 100-250g |

| 8.4-12.2mm | 120-400g |

(PS: For round metal dome, when its diameter is larger, the force can even reach 200g to 400g.)

As we know that the force of metal domes is also related to the lifetime. Therefore, the magnitude of force still depends on the customer’s requirement. if the customer has no requirements about the lifetime, we can increase the force at discretion as well.

How Do I Choose the Right Dome for My Keyboard?

Choosing the right dome for your keyboard involves considering several factors, including the type of device, the user’s needs, and the overall design of the keypad. The first step is to determine the level of tactile feedback that is required. If the device is used frequently, a dome with a higher actuation force might be necessary to prevent accidental presses. However, for applications where speed is more important, a lighter dome might be better suited.

Other factors to consider include:

- Dome Shape: The shape of the dome affects the feel of the press. Four-legged domes provide stability, while triangular or round domes offer varying levels of precision and softness.

- Dome Material: Most metal domes are made from stainless steel, but different finishes can be applied to alter the feel and durability of the dome.

- Dome Size: Larger domes tend to provide a softer feel, while smaller domes give more resistance and a firmer press.

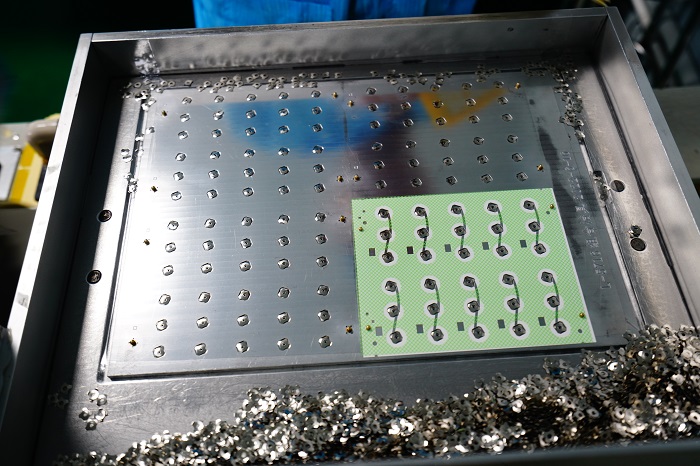

Best Technogy – Your Reliable Keyboard Metal Dome Manufacturer

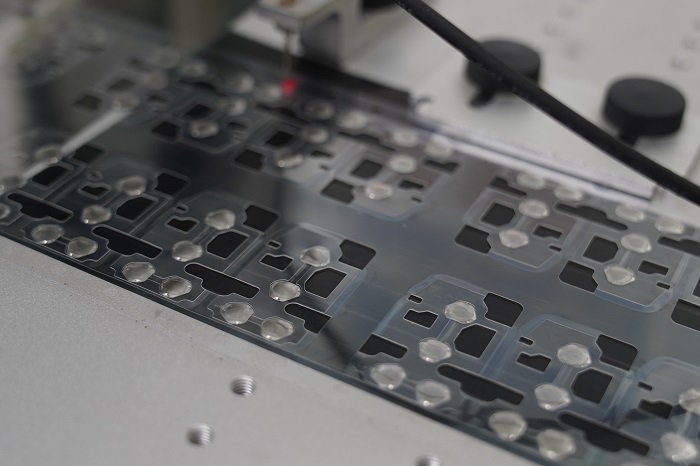

Best Technology is known for producing high-quality metal domes for a variety of applications, including keyboards, remote controls, and other input devices. We offer a wide range of dome options, ensuring that you can find the perfect fit for your device. Whether you need a four-legged dome for stability or a triangular dome for precision, Best Technology has you covered.

With a focus on quality, durability, and customization, Best Technology provides metal domes that meet the unique needs of their clients. If you are looking for a reliable partner for your metal dome requirements, Best Technology is an excellent choice.