Are you facing the following problems?

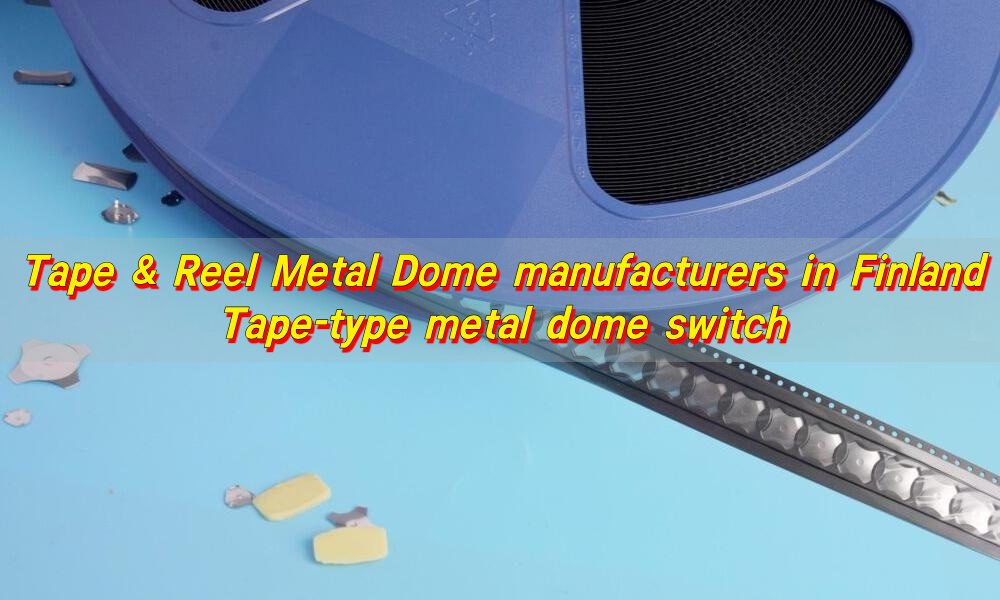

- Difficulty finding a fast and reliable local Tape & Reel Metal Dome supplier in Finland.

- Inconsistent quality of pressure-sensitive metal domes, leading to inconsistent product performance.

- Numerous design specifications, but manufacturers are unable to provide customized services.

- Long lead times and slow response times, impacting production schedules and time-to-market.

- Inability to obtain Tape & Reel Packaging specifications suitable for automated assembly.

- Existing suppliers lack quality certifications or rigorous testing capabilities.

End-to-End Support from Demand to Delivery: Our Solution

As a professional Tape & Reel Metal Dome manufacturer, we provide one-stop support from design and prototyping to production and delivery.

We deeply understand our customers’ pain points and, through strict quality control, multi-specification customization, and a rapid response mechanism, make cooperation easier and more efficient. From design review and sample debugging to production monitoring and packaging delivery (including Tape & Reel Packaging), we guarantee transparent progress and high-quality service, allowing customers to place orders with confidence and receive products reliably.

Why Choose Us? EBest Circuit (Best Technology)’s Core Advantages

As a leading Tape & Reel Metal Dome manufacturer in the industry, we possess the following core advantages:

- High-precision manufacturing capabilities: Advanced stamping and automation processes ensure consistent precision and extended lifespan for every metal dome.

- Rich selection of performance parameters: Supports customization of various shapes, elasticity, and tactile specifications to meet different application needs.

- Strict quality system: Rigorous control throughout the entire process, from material selection and stamping to factory testing.

- Fast response and delivery capabilities: Able to quickly prototype based on designs and provide short lead times (samples and small batches can be arranged quickly).

- Professional technical support: Provides detailed technical consulting, standard documentation, and application suggestions to reduce design risks.

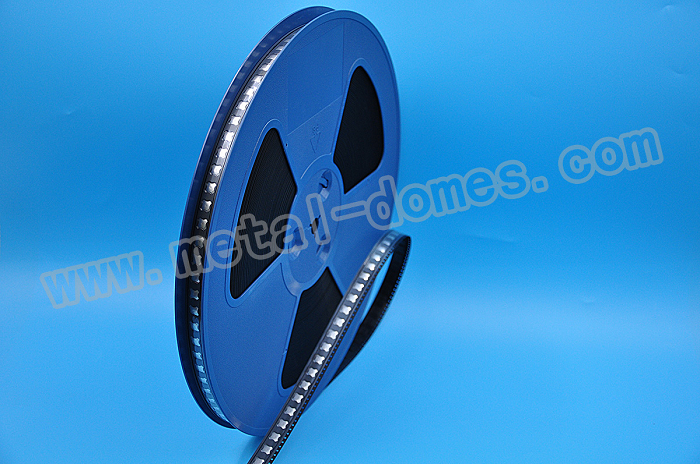

- Tape & Reel Packaging support: Accommodates automated assembly requirements, improving production efficiency.

These advantages make us a reliable partner for many global electronic manufacturing projects.

Finland Tape & Reel Metal Dome Manufacturers

Top 10 Tape & Reel Metal Dome manufacturers in Finland

| Company Name | Process Capability | Main Advantage |

|---|---|---|

| EBest Circuit (Best Technology) | Metal dome design and automated stamping; Tape & Reel packaging | Emphasis on customization capability, stable quality, fast delivery |

| ComProg Electronics Oy | Electronic design, material procurement and manufacturing | Provides component procurement and integrable services (including PCB assembly) |

| Prinel Piirilevy Oy | PCB production and component procurement | Emphasizes supply chain management and assembly support |

| Aspocomp Group Plc | PCB manufacturing and design services | Local PCB production capability in Finland |

| Dicro Oy | Electronic and electromagnetic component manufacturing | Contract manufacturing capability and electromagnetic component production |

| Elektroval Oy | PCB manufacturing and assembly | Local PCB supply capability |

| Jopaco Electronics Oy | Electronic manufacturing services (EMS) | EMS support in Finland |

| Muurlan Elektroniikka Oy | Electronic manufacturing and assembly services | Full-chain electronic manufacturing services |

| Sanmina Haukipudas (Finland) | PCBA manufacturing and supply chain management | Supported by global supply chain |

| Cadmic | PCB and component services | Electronic industry service provider |

How to choose a Finland Tape & Reel Metal Dome manufacturer?

When choosing a suitable supplier, consider the following criteria:

- Does it support Tape & Reel Packaging? — Is automated assembly packaging available?

- Manufacturing precision and tolerance control capabilities — High-precision stamping and process stability.

- Certifications and quality system — Does it have industry certifications such as ISO9001?

- Product customization capabilities — Does it support custom designs with different sizes and spring force parameters?

- Supply chain and component support capabilities — Can it provide component procurement support?

- Delivery time management level — Can it guarantee short-cycle orders?

- Technical support capabilities — Does it have a professional engineering team to provide design advice?

- Testing and acceptance procedures — Test coverage and reliability testing procedures.

EBest Circuit (Best Technology) stands out in customization capabilities, delivery time guarantees, automated packaging, and quality systems, making it a preferred partner.

Core Pain Points of Finland Tape & Reel Metal Dome Manufacturers

| Core Pain Points | Our Solutions |

|---|---|

| Complex specification design, difficult to implement quickly | Provide sample validation and engineering design support to shorten the verification cycle |

| Unstable supply, batch quality fluctuations | Strict quality control and batch tracking system |

| No Tape & Reel automatic mounting support | Provide standardized Tape & Reel Packaging |

| Long delivery cycles | Activate rapid response mechanisms and short delivery time solutions |

| Incomplete component procurement, complex supply chain | We can assist with procurement and optimize the supply chain |

EBest Circuit (Best Technology) effectively solves most of the above manufacturing and supply chain pain points through professional processes and service procedures.

How to analyze the production capacity of a Finland Tape & Reel Metal Dome manufacturer?

- Before choosing a supplier, it is recommended to check the following indicators:

- Production capacity (daily/weekly output).

- Automation equipment (stamping machines, packaging lines, etc.).

- Quality testing equipment (such as life testing, contact resistance testing, etc.).

- Process throughput and personnel experience.

- Customization and R&D capabilities.

- Material sourcing and control capabilities.

- Supported shape/size range.

- Manageable batch sizes and traceability system.

EBest Circuit (Best Technology) not only has stable production capacity and automated equipment but also possesses R&D customization capabilities and strict quality testing procedures, fully meeting the needs of complex projects.

How to evaluate the delivery time of a Finland Tape & Reel Metal Dome manufacturer?

When evaluating delivery time, consider:

- Order processing speed.

- Line-side inventory management.

- Sample plan and prototyping cycle.

- Mass production arrangements.

- Logistics and packaging arrangements.

- Whether Tape & Reel pre-packaging is provided.

- Emergency order handling mechanism.

- Delivery time commitment and penalty mechanism for breach of contract.

As a manufacturer, we provide fast small-batch shipments in as little as 2-3 days to help customers shorten development and iteration cycles.

Finland Tape & Reel Metal Dome Manufacturer Frequently Asked Questions (FAQ)

Q1: What is the minimum order quantity for Tape & Reel Metal Domes?

A: Depending on the design and specifications, the minimum order quantity can be as low as a few thousand pieces, or customized in bulk per project. Specific details need to be confirmed based on specifications and packaging requirements.

- Q2: How do you ensure consistent tactile feel for each batch of Metal Domes?

A: We ensure consistent tactile feel and lifespan through strict process control, consistent material selection, and full inspection/sampling mechanisms.

- Q3: I don’t have design drawings, can you provide design support?

A: Yes, we provide engineering design assistance services and can assist in drawing specification diagrams and suggesting optimizations as needed.

- Q4: Does Tape & Reel Packaging include labels and tracking information?

A: Yes, automated assembly packaging usually includes clear batch numbers and labels for convenient production management.

- Q5: How long is the typical lead time?

A: Samples are usually available within a few days, and mass production lead times depend on the order quantity, but we can provide expedited shipping options.

- Q6: How do you test the lifespan and stability of metal domes?

A: We use fatigue life testing machines and contact resistance testers for batch verification.

- Q7: Can different sizes of domes be mixed in one order?

A: Mixing different sizes is generally not recommended, but if there are special requirements, we can customize the order according to customer needs.

- Q8: How do you handle defective batches or quality disputes?

A: We have a comprehensive after-sales service system. Any quality issues will be promptly remedied or replaced after confirmation.

Summary:

With our comprehensive process practices and rapid response system, we are your preferred partner among Tape & Reel Metal Dome manufacturers in Finland; whether it’s design, prototyping, or mass production delivery, you can place orders with confidence and rely on stable supply.