Custom Metal Domes Factory Greece — Serving the industrial control, medical equipment, consumer electronics, and automotive electronics sectors, Dome array manufacturers in Greek are transitioning from traditional processing to high-consistency and automated delivery. For customers seeking high lifespan, consistent tactile feel, and fast delivery times, choosing experienced and standardized Greek dome array manufacturers will directly determine product reliability and overall project progress.

Are you facing these problems?

- Long prototyping cycles, with repeated modifications failing to achieve consistent tactile feel and rebound requirements.

- Small batch orders are neglected, high MOQ, and high communication costs.

- Insufficient dome array positioning accuracy, resulting in low SMT placement yield.

- Inconsistent material batches, leading to inconsistent lifespan test data.

- Lack of complete technical documentation and compliance certifications (ROHS/REACH).

A comprehensive solution from requirements to delivery

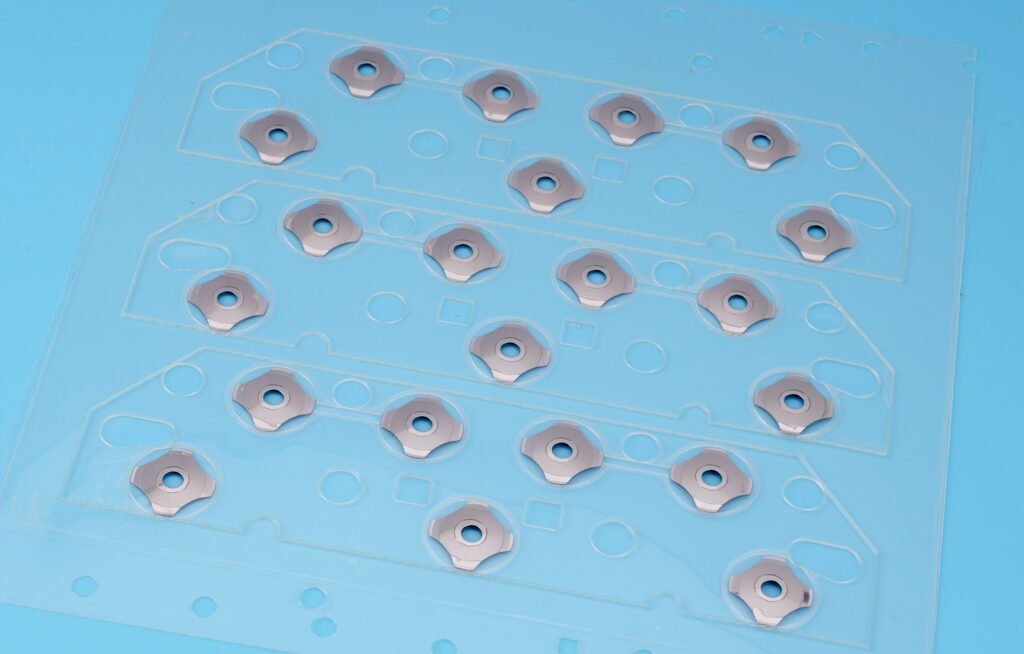

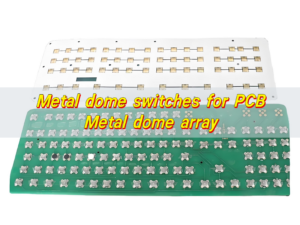

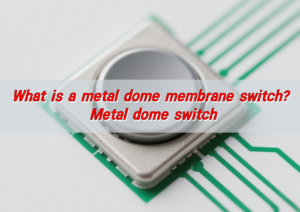

As a professional metal dome array manufacturer, we have established an integrated system from structural evaluation -> material selection -> mold development -> array design -> reliability testing -> automated packaging -> fast delivery:

- Our engineering team is involved from the drawing stage to optimize tactile curves and installation tolerances.

- We use high-consistency stainless steel materials and multi-stage rebound control processes.

- We offer various packaging methods including Tape & Reel, single domes, and arrays.

- Lifespan testing and pressure curve sampling are performed on each batch.

- Sample design evaluation is completed within 72 hours, shortening the project start-up cycle.

Our goal is not only to deliver products but also to help customers reduce rework rates, improve assembly efficiency, and shorten time to market.

Why choose us? EBest Circuit (Best Technology)’s core advantages

- 20+ years of focus on metal dome and array manufacturing, with mature and stable processes.

- Array positioning accuracy of ±0.05mm, suitable for high-speed SMT placement.

- Lifespan exceeding 1 million press cycles, ensuring long-term reliability.

- Supports OEM/ODM customization, with fully adjustable size, force, and structure.

- Dual production bases in China and Vietnam, ensuring stable delivery times and controllable risks.

- 48-hour technical response mechanism + free initial samples + complete parameter data.

Top 10 dome array manufacturers in Greece

| Company Name | Process Capability | Main Advantage |

|---|---|---|

| EBest Circuit (Best Technology) | Metal dome stamping, array lamination, Tape & Reel automatic packaging | High-precision array design, million-cycle lifespan, 7-day delivery, ODM support |

| Greek Micro Components | Single dome stamping | Local delivery |

| Athens Switch Solutions | Array lamination | Small batch flexibility |

| Hellenic Electronics Parts | Metal stamping | Lower cost |

| Patras Precision Metals | Stainless steel forming | Customization capability |

| Aegean Industrial Devices | Electronics assembly | System integration |

| TechHellas Components | Dome processing | Local communication |

| MedTech Switch Systems | Medical applications | Compliance experience |

| Ionian Electronics | Small array | Fast sample service |

| Balkan Keypad Solutions | Outsourced production | Price competitiveness |

How to choose a Greece dome array manufacturer?

- Does the manufacturer have array positioning accuracy control capabilities?

- Does the manufacturer provide life cycle testing and pressure curve data?

- Does the manufacturer support automated assembly and packaging methods (Tape & Reel)?

- Does the manufacturer have a mature engineering support team?

- Does the manufacturer have experience in delivering to international customers?

- Can the manufacturer provide rapid prototyping?

- Does the manufacturer provide material and certification documents?

- Does the manufacturer have the capacity for large-scale mass production?

Why is EBest Circuit (Best Technology) the best choice?

We not only meet all the above conditions, but also significantly lead in array stability, automated packaging, delivery speed, and technical response capabilities. For customers who require a long-term stable supply chain and high-yield production, we can provide lower overall procurement costs and higher assembly efficiency.

Core pain points of Greece dome array manufacturers

- Insufficient process stability —> We use standardized stamping modules and multi-point inspection

- Large array alignment deviation —> Array positioning accuracy controlled within ±0.05mm

- Insufficient life cycle testing —> Million-cycle press testing for each batch

- Low degree of automation —> Provides Tape & Reel high-speed assembly solutions

- Low engineering communication efficiency —> Technical feedback within 48 hours

- Limited expansion capacity —> Dual factory capacity scheduling

- Uncontrollable delivery time —> Standard orders completed within 7 days

How to analyze the production capacity of a Greece dome array manufacturer?

- Monthly production capacity

- Ratio of automated equipment

- Number of molds and maintenance system

- Number of engineering personnel

- Quality inspection process

- Batch consistency control

- Raw material sources

- Does it support multiple packaging methods?

- Does it have international logistics experience?

EBest Circuit (Best Technology) possesses: a mature automated production line, a stable raw material supply chain, a standardized quality system (ISO9001:2015), and has long-term service experience with European and American customers, with the ability to deliver large quantities and high consistency simultaneously.

How to evaluate the delivery time of a Greece dome array manufacturer?

- Prototyping cycle

- Mold development cycle

- Raw material inventory

- Does it support parallel production?

- Does it have backup production capacity?

- Does it offer expedited options?

- Does it have historical delivery records?

- Does it support international direct shipping?

EBest Circuit (Best Technology) can achieve:

- Samples: 2–3 days

- Small batches: 5–7 days

- Bulk orders: Stable production scheduling + pre-booked capacity

Frequently Asked Questions (FAQ) about Greece dome array manufacturers

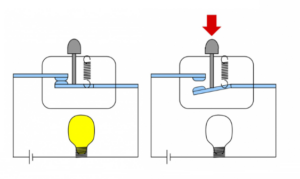

- Q1: Why do array domes often have inconsistent tactile feel?

A: This usually stems from different material batches or excessive alignment tolerances. It is recommended to choose a manufacturer with pressure curve testing capabilities.

- Q2: Is Tape & Reel packaging mandatory?

A: If using high-speed SMT placement equipment, it is strongly recommended, as it can increase assembly efficiency by four times.

- Q3: What is the standard for Dome lifespan testing?

A: For industrial applications, ?500,000 cycles are recommended; for high-reliability applications, ?1,000,000 cycles are recommended.

- Q4: Is it possible to customize different actuation forces?

A: Yes, this can be achieved through adjustments to material thickness, structural shape, and molds.

- Q5: How to avoid delivery delays?

A: Choose a supplier with stable production capacity and a dual-factory layout.

- Q6: Are certification documents required?

A: For export projects, ROHS, REACH, and material reports are recommended.

Conclusion:

When choosing Greece Metal dome array manufacturers, what truly determines the long-term value of the partnership is not the price, but rather stability, delivery capability, and engineering support level. EBest Circuit (Best Technology) is a reliable partner among many Greece Metal dome array manufacturers that can simultaneously meet the requirements of high precision, long lifespan, and fast delivery.