As a key component widely used in electronic control and human-machine interfaces, New Zealand’s dome array manufacturers are attracting increasing attention from both local and international customers.

Considering manufacturing experience, technical capabilities, and delivery performance, few of New Zealand’s top 10 dome array manufacturers possess complete solution capabilities, and EBest Circuit (Best Technology) is a proven and reliable choice for long-term partnerships.

Are you facing the following problems?

- Long prototyping cycles, repeated communication, and designs that require multiple revisions

- Small batch production is possible, but mass production consistency is poor, and yield is unstable

- Inconsistent dome tactile feel, and difficulty controlling rebound force and lifespan

- Uncontrollable delivery times, with project plans repeatedly delayed by the manufacturing side

- Limited capabilities of local suppliers, and low cooperation from overseas suppliers

End-to-end assurance from requirements to delivery: Our solution

From the customer’s initial structural requirements, tactile feel requirements, and lifespan standards, EBest Circuit (Best Technology) intervenes in the Design for Manufacturability (DFM) assessment of the Dome Array, mitigating risks in the design phase.

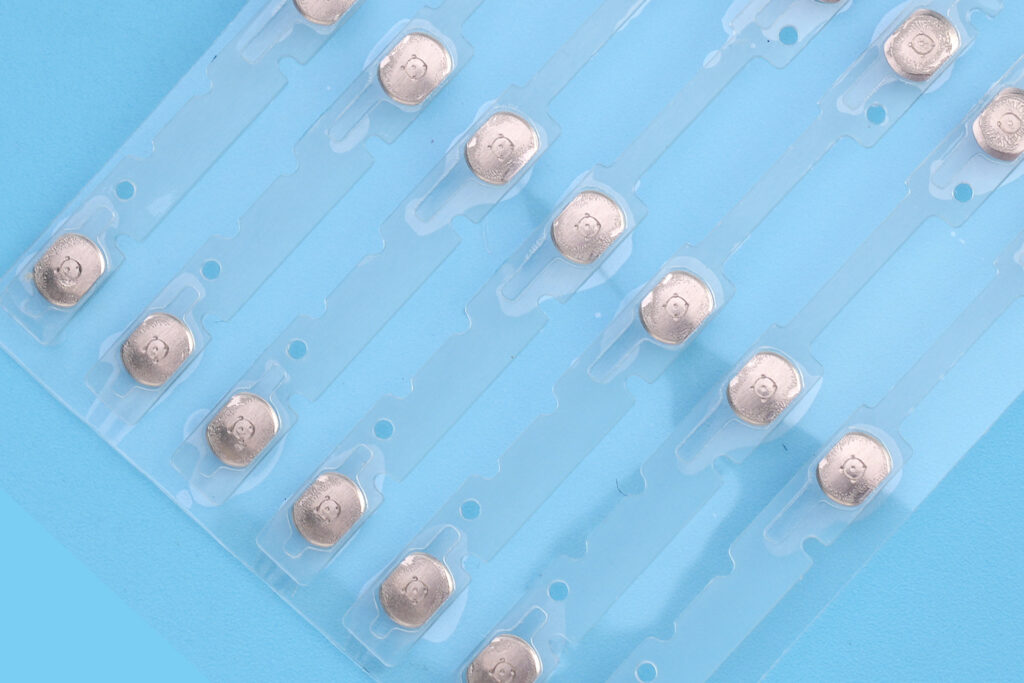

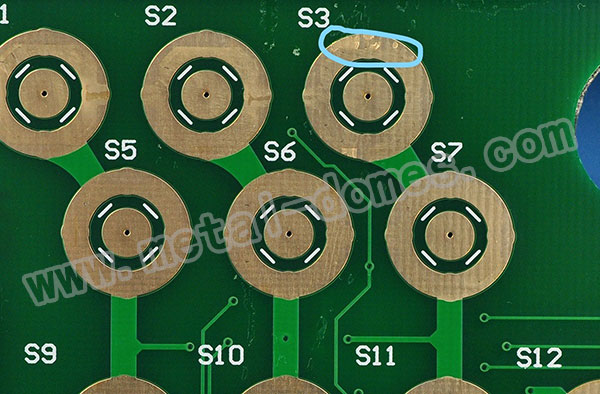

Through integrated management of our own mold development, metal dome forming, bonding, and testing processes, we ensure that every Dome Array remains completely consistent during both prototyping and mass production. At the same time, a professional engineering team provides full support, shortening communication channels and allowing customers in New Zealand to enjoy a highly efficient, predictable, and reproducible Dome Array delivery experience.

Why choose us? EBest Circuit (Best Technology)’s core advantages

- 20+ years of Dome Array manufacturing experience: Long-term service to industrial control, medical, communication, and automotive electronics customers

- Integrated design and manufacturing: From dome structure and tactile feel to array layout, the entire process is controllable

- High-consistency mass production capabilities: Lifespan of over 1,000,000 cycles, stable batches

- Fast prototyping and delivery: Quick sample response, no project delays

- International compliance standards: Full support for ISO9001, RoHS, and REACH

- Dedicated engineering support: Not sales representatives, but engineers directly solving problems

These advantages lead customers to entrust their orders to us for long-term partnerships after their initial collaboration.

Top 10 dome array manufacturers in New Zealand

| Company Name | Main Business / Process Capability | Advantage Notes |

|---|---|---|

| EBest Circuit (Best Technology) | Dome Array Design / Sample Prototyping / Mass Production / Tape & Reel Packaging | High-precision array, fast delivery, full-process manufacturing |

| Active Components Ltd | Electronic component supply and technical support | Local inventory and technical consultation support, quick access to components and samples |

| 2 Way Industries Ltd | Precision metal processing, manufacturing subcontracting | Precision metal component manufacturing, can provide processing for Dome Array structural parts |

| Adept Ltd | End-to-end solutions from design to manufacturing | Provides contract manufacturing and engineering support, can interface with electronic component production |

| Jaycar New Zealand | Electronics and electromechanical component distribution | Provides switch and related electronic component inventory support |

| ManufacturingNZ Member Manufacturers Collection | Multi-domain manufacturing resource directory | Provides customizable manufacturing services |

| Element14 NZ | Electronic component distribution and design support | Global component supply and technical consultation |

How to choose a New Zealand dome array manufacturer?

- Do they possess design capabilities for dome determinants (tactile feel, rebound, lifespan)?

- Can they support the complete process from prototyping ? small-batch production ? mass production?

- Do they have stable mold and stamping process control?

- Can they provide consistency and lifespan data support?

- Do they have experience with international customer projects?

- Do they have clear and executable delivery time commitments?

Why is EBest Circuit (Best Technology) the best choice?

We don’t just get involved at the array assembly stage; we participate from the very beginning, defining the dome’s structure and tactile parameters. Our engineering team reverse-engineers the dome diameter, pressure curve, rebound height, and lifespan requirements based on the customer’s application scenario (industrial, medical, consumer electronics, etc.), and completes manufacturability verification during the design phase.

This approach of controlling from the source means that customers don’t need to repeatedly change suppliers or redesign during the prototyping, trial production, and mass production stages, which is a key reason why we become long-term partners.

Core pain points of New Zealand dome array manufacturers

- Mass production not considered during the design phase, leading to frequent modifications later

- Significant differences in dome feel between different batches

- Delivery time dependent on outsourcing, making planning uncontrollable

- Insufficient process capabilities, resulting in low yield

- Multiple communication channels, unclear responsibilities

EBest Circuit (Best Technology)’s solutions:

- Early DFM (Design for Manufacturability) assessment to avoid designs that are not manufacturable

- In-house stamping and testing to ensure consistent tactile feel

- Key processes are handled internally, ensuring independent control of delivery times

- Standardized quality processes to improve yield

- Single point of contact for engineering, ensuring efficient communication

How to analyze the production capabilities of a New Zealand dome array manufacturer?

- Do they own their own stamping equipment?

- Can they control dome tolerances?

- Do they have lifespan testing capabilities?

- Do they support various array forms?

- Do they have batch stability?

- Do they have a quality traceability system?

EBest Circuit (Best Technology) fully meets all the above conditions and, through years of project accumulation, has formed a mature dome array manufacturing system that can stably support long-term, large-volume orders.

How to evaluate the delivery time of a New Zealand dome array manufacturer?

- Is the prototyping cycle clearly defined?

- Is the mass production cycle stable?

- Are there any outsourced key processes?

- Do they have emergency production scheduling capabilities?

- Can they support project milestone delivery?

EBest Circuit (Best Technology), through internal collaboration and a mature production scheduling system, can achieve rapid sample delivery in 2-3 days, helping customers significantly shorten project cycles. At the same time, because all core processes are completed in-house, we can flexibly adjust the production sequence according to customer project priorities, rather than being constrained by the schedules of external factories.

New Zealand Dome Array Manufacturer Frequently Asked Questions

- Q1: Why are Dome Array prototypes always subject to repeated revisions?

A: This is often due to the lack of consideration for mass production feasibility in the initial design phase. We intervene in the design stage to reduce rework.

- Q2: What if the feel of the Dome Arrays varies between different batches?

A: This requires a stable stamping and testing system. We have full process internal control to ensure consistency.

- Q3: What if small-batch production is possible, but mass production cannot keep up?

A: This is a typical process discontinuity problem. EBest Circuit (Best Technology) operates according to mass production standards from the very beginning.

- Q4: What if unstable delivery times affect the project?

A: In-house manufacturing of key processes, avoiding reliance on outsourcing, is the core reason for our stable delivery times.

When choosing a Dome Array supplier in the New Zealand market, the key is not the quantity, but the capability and reliability; among the top 10 dome array manufacturers in New Zealand, EBest Circuit (Best Technology) stands out as a trustworthy choice due to its stable manufacturing, fast delivery, and long-term partnership capabilities.