Slovenia manufacturer of dome array solutions typically serves European OEMs that require stable tactile feedback, consistent actuation force, and long product lifecycles. In industrial control panels, medical devices, and communication equipment, dome arrays must deliver precise snap ratios and reliable electrical contact while meeting strict EU compliance standards.

Are you facing the following problems?

- Long prototyping cycles for dome arrays, unable to quickly respond to product development progress, delaying project launch time.

- Manufacturing precision is substandard, resulting in poor adhesion between the dome and the PCB board, leading to unstable button sensitivity and affecting the quality of the final product.

- Lack of targeted design solutions, unable to optimize the dome array layout based on product structure and usage scenarios, resulting in the risk of button interference.

- Significant quality fluctuations during mass production, resulting in high defect rates, increasing production and rework costs.

- Unreliable delivery times, with delays during peak seasons or for urgent orders, disrupting production plans.

End-to-end process guarantee from demand to delivery: EBest Circuit (Best Technology)

We deeply understand the core role of dome arrays in electronic devices and are always guided by customer needs. Our professional team provides full-process support, precisely controlling every aspect: during the demand phase, we thoroughly communicate product parameters, usage environment, and performance requirements to provide customized solutions; during the production phase, we use high-precision equipment and strict quality control standards to ensure product consistency; during the delivery phase, we cooperate with high-quality logistics partners to guarantee on-time delivery. Choose us, and make your dome array procurement easier and more reliable.

Why choose us? The advantages of EBest Circuit (Best Technology)

- Over 20 years of professional experience in the industry: As a seasoned dome array manufacturer in Slovenia, we have a mature production system and rich project experience, and have provided high-quality products to customers in various fields such as consumer electronics, industrial control, and automotive electronics.

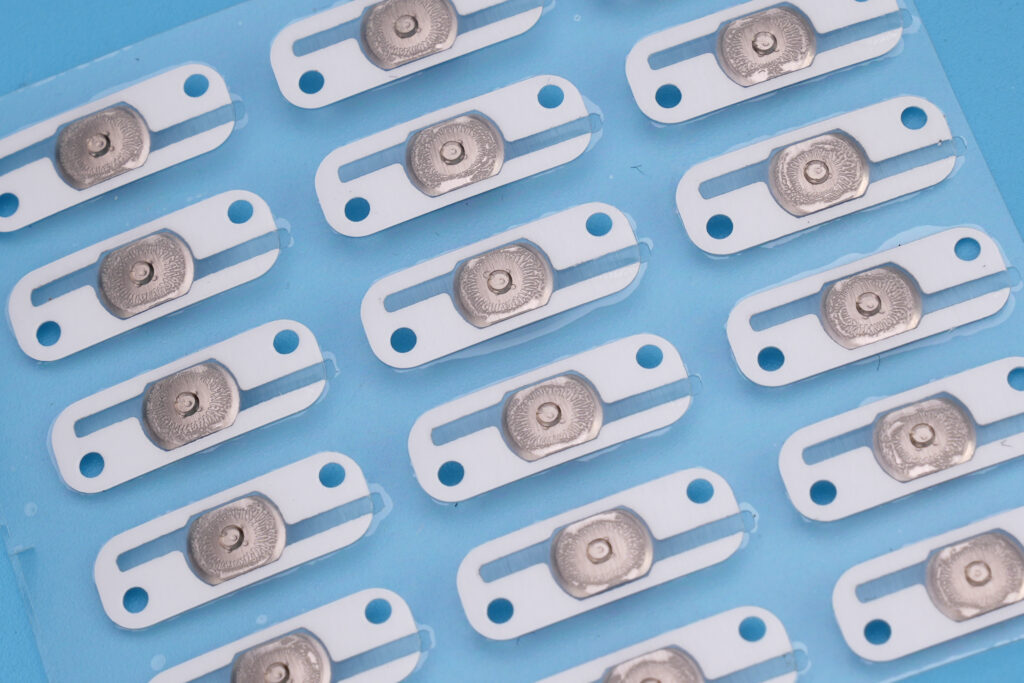

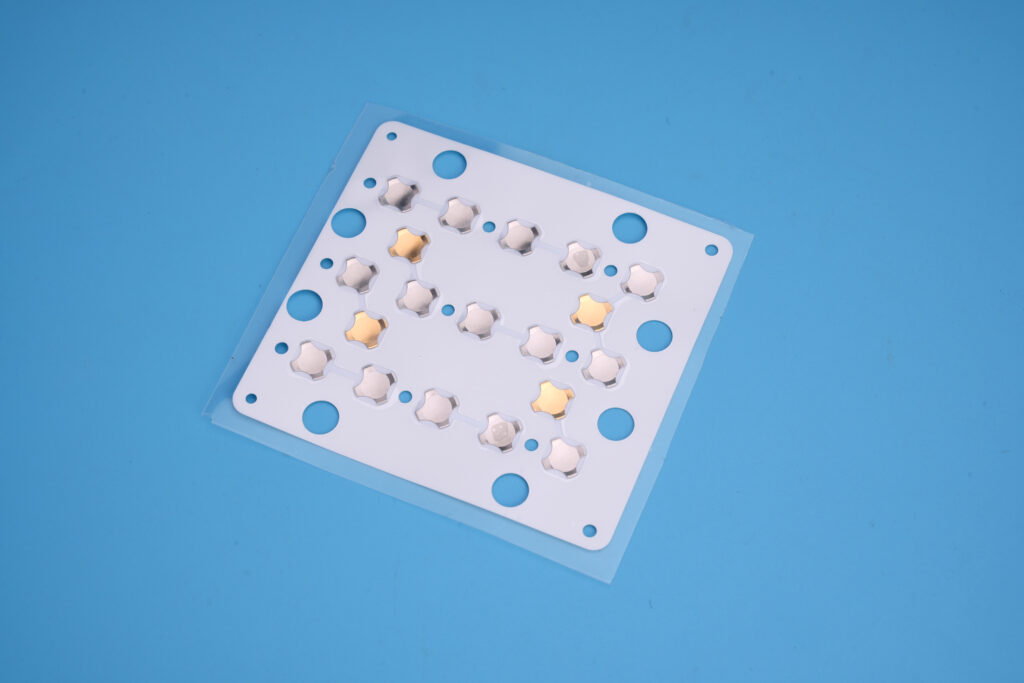

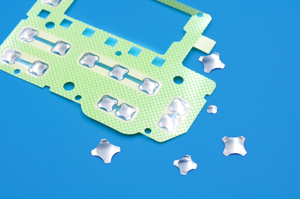

- High-Precision Production Equipment and Processes: Equipped with imported precision stamping equipment, automated assembly lines, and professional testing instruments, we achieve stringent standards of ±0.005mm thickness tolerance and ±0.1mm positioning accuracy for domes, ensuring stable product performance.

- Fully Customized Service Capabilities: We provide fully customized services from solution design and prototyping to mass production based on customer PCB drawings, button layouts, and pressure requirements, flexibly meeting the personalized needs of different products.

- Strict Quality Control System: We have established a three-level quality inspection process from raw material procurement and production to finished product delivery. All raw materials are made of high-elasticity, long-life stainless steel, and the finished product defect rate is controlled below 0.3%, ensuring that every batch of products delivered meets the standards.

- Fast Response and Delivery Capabilities: Our professional design team responds to requests within 24 hours, with a minimum prototyping cycle of 1 day, and regular mass orders delivered within 3-7 days. Urgent orders can be expedited within 24 hours, ensuring timely project completion for our customers.

- Comprehensive After-Sales Service System: We provide free technical consulting, product trials, and free returns and exchanges for defective products. We continuously follow up on product usage after delivery and promptly resolve any issues, giving our customers peace of mind.

List of dome array manufacturers in Slovenia

Top 10 dome array manufacturers in Slovenia

| Company Name | Process Capability | Advantage |

|---|---|---|

| EBest Circuit (Best Technology) | Precision stamping (Tolerance ±0.005mm), automated assembly, laser cutting, 100% full inspection; Can process 0.05-0.15mm thickness stainless steel, supports 1-100 key Dome array customization | 20+ years industry experience, fully customized service, 1-day sample delivery, defect rate <0.3%, comprehensive after-sales guarantee |

| Slovenia Metal Dome Co., Ltd. | Standard stamping forming, manual-assisted assembly, supports standard model Dome array production, material thickness 0.08-0.12mm | Sufficient local production capacity, standard products available in stock, cost-effective, suitable for bulk standard orders |

| Euro Dome Solutions | Precision stamping, semi-automated assembly, simple customization capability, can handle special shape Dome design, inspection accuracy ±0.2mm | Mature European market channels, convenient logistics, focused on mid-to-high-end consumer electronics |

| Techno Press Slovenia | Multi-station stamping, mold development, supports Dome array mold customization, materials include stainless steel, copper alloy | Strong mold development capability, suitable for long-term customized projects, high efficiency in mass production |

| Elite Dome Manufacturing | Automated stamping, finished product inspection, supports small batch customization, sample lead time 2-3 days, material thickness 0.06-0.15mm | Quick response for small batch orders, stable quality, focused on industrial control equipment |

| Slovenia Precision Components | Precision stamping, manual assembly, can produce high-pressure Dome array, suitable for special industrial scenarios | Mature high-pressure product technology, excellent wear resistance, targeted customized solutions |

| Dome Tech Europe | Standard stamping, standardized assembly, supports PCB design suggestions for Dome array, complete inspection process | Provides integrated supporting services, professional technical consultation, suitable for new customers |

| Metallic Dome Slovenia | Semi-automatic stamping, batch assembly, mainly produces standard model Dome array, stable capacity | Significant bulk price advantage, stable delivery cycle, suitable for large-scale standardized orders |

| Pro Dome Manufacturing | Precision stamping, laser engraving, can achieve special marking customization on Dome surface, inspection accuracy ±0.15mm | Outstanding special process capability, detailed customization, suitable for high-end product support |

| Slovenia Electronic Components | Standard stamping, simple assembly, supports repair/replacement parts production for Dome array, universal materials | Ample stock of replacement parts, fast response, low cost, suitable for maintenance market demand |

How to choose a Slovenia dome array manufacturer?

- Examine the manufacturer’s industry experience: Prioritize manufacturers with a long history in the industry and extensive project experience to avoid product issues due to lack of experience.

- Evaluate production equipment and process level: Understand whether the manufacturer is equipped with precision stamping equipment, automated production lines, and professional testing instruments. Equipment precision directly affects product quality.

- Confirm customization capabilities: Inquire whether they can design solutions and provide samples according to customer needs, and whether they can flexibly handle personalized parameter requirements.

- Verify quality control system: Understand the manufacturer’s quality inspection process, raw material procurement standards, and defect rate control, and request relevant quality certification documents.

- Understand delivery capabilities: Clarify the sampling cycle and mass production delivery cycle, and confirm whether they can handle urgent orders to avoid project delays.

- Examine after-sales service: Inquire whether they provide technical consulting, product trials, and defective product handling services. Comprehensive after-sales service can reduce subsequent cooperation risks.

- Refer to customer reviews and reputation: Understand the manufacturer’s reputation through industry cases and customer feedback, and choose a manufacturer with high market recognition.

- Compare price reasonableness: While ensuring quality and service, choose a manufacturer with transparent pricing and high cost-effectiveness, avoiding low-price, low-quality traps.

EBest Circuit (Best Technology) is the optimal choice for selecting a Slovenia dome array manufacturer. We fully meet all the above selection criteria and have core advantages in multiple dimensions. Our fully customized team responds to needs 24/7, and our fast delivery capabilities adapt to various order rhythms. Choosing us means choosing a stable, efficient, and professional dome array supply partner.

Core Pain Points of Slovenian Dome Array Manufacturers

- Unstable raw material supply: Core raw materials such as high-quality stainless steel rely on imports, resulting in long procurement cycles and significant price fluctuations, impacting production plans and cost control.

- Difficulty in controlling production precision: Dome arrays have stringent dimensional tolerance requirements, and ordinary equipment struggles to consistently meet precision standards, leading to quality fluctuations.

- Insufficient customization capabilities: Lack of a professional design team prevents quick responses to customers’ personalized needs, making it difficult to handle customized orders with complex structures.

- Low production efficiency: Some manufacturers still use manual or semi-automatic production modes, resulting in limited capacity, inability to meet large-scale order demands, and long delivery cycles.

- Incomplete quality inspection system: Lack of full-process testing equipment and standards leads to a high defect rate in finished products, resulting in increased customer complaints and rework costs.

- Lagging technological updates:Â Failure to respond promptly to the demand for dome arrays in new electronic devices, coupled with outdated processes and design concepts, results in a lack of competitiveness.

- Lack of after-sales service:Â Prioritizing production over service, slow response to customer technical inquiries and defective product handling negatively impacts customer loyalty.

EBest Circuit (Best Technology), with its comprehensive system and core advantages, can fully address the above pain points:

- 1) Establishing long-term strategic partnerships with global high-quality raw material suppliers, signing stable supply agreements, locking in price fluctuations, and ensuring sufficient raw material supply;

- 2) Investing heavily in imported precision stamping and testing equipment, establishing standardized production processes, and achieving stable precision control;

- 3) Building a professional customized design team equipped with advanced design software to quickly respond to various personalized needs;

- 4) Adopting fully automated production lines to significantly improve production efficiency, increase capacity reserves, and shorten delivery cycles;

- 5) Establishing a comprehensive after-sales service team to respond to customer needs 24/7, quickly resolving various issues and enhancing customer loyalty.

How to analyze the production capabilities of Slovenian dome array manufacturers?

- Review production equipment configuration: Understand the manufacturer’s stamping equipment, assembly equipment, and testing equipment models, precision, and quantity.

- Assess production capacity: Inquire about the manufacturer’s monthly and annual production capacity and understand the efficiency of their production lines.

- Evaluate the degree of production process standardization: Observe the manufacturer’s production site management and whether they have complete production process specifications and work instructions.

- Understand the technical team’s capabilities: Inquire about the number of technical personnel, their work experience, and professional qualifications.

- Verify quality testing capabilities: Understand the testing items, the precision of testing equipment, and the testing process, and whether full-batch and full-item testing is implemented.

- Examine the raw material supply system: Understand the raw material procurement channels, inventory reserves, and supplier qualifications.

- Review past production cases: Understand whether the manufacturer has undertaken orders similar to your needs, especially large-scale or highly complex customized orders.

- Assess emergency production capabilities: Inquire about the manufacturer’s solutions for handling urgent orders, equipment failures, raw material shortages, and other emergencies.

EBest Circuit (Best Technology) fully meets and exceeds the above production capacity analysis standards, possessing industry-leading production capabilities, establishing a strict production process standardization system, and having complete work instructions and on-site management specifications to ensure stable production and delivery.

How to Evaluate the Delivery Time of a Slovenia Dome Array Manufacturer?

- Clarify standard delivery times: Ask the manufacturer about their typical prototyping cycle, small batch order cycle, and large batch order cycle, and confirm if they have a clear time commitment.

- Assess production capacity: Understand the manufacturer’s current capacity utilization and whether they have additional capacity reserves.

- Evaluate the rationality of the production plan: Understand the manufacturer’s order scheduling system and whether they can reasonably arrange production based on customer order priorities.

- Review supply chain coordination capabilities: Understand the raw material procurement cycle and component supply situation.

- Inquire about emergency order processing capabilities: Confirm whether the manufacturer supports expedited production, the delivery cycle for expedited orders, and the corresponding charges.

- Understand logistics and distribution cooperation: Ask about the manufacturer’s logistics service providers and whether they have established logistics channels.

- Refer to past delivery records: Understand whether the manufacturer can fulfill delivery commitments through customer cases and feedback.

- Confirm delivery guarantee mechanisms: Ask the manufacturer if they have compensation measures for delivery delays.

EBest Circuit (Best Technology) has a significant advantage in delivery time guarantees, enabling fast delivery. Regular prototyping is completed in 1 day, small batch orders are delivered in 2-3 days, large batch orders in 3-7 days, and urgent orders can be expedited and delivered within 24 hours.

We have signed long-term agreements with core raw material suppliers to ensure timely supply of raw materials; we cooperate with 3 top-tier logistics service providers to provide fast delivery services covering Slovenia and Europe; our on-time delivery rate is 99.8%, fully guaranteeing the progress of customer orders. Choose us to completely eliminate your worries about delivery delays.

Frequently Asked Questions about Slovenia Dome Array Manufacturers

- Q: What is the lifespan of the dome array?

A: We use high-elastic stainless steel material, processed with precision technology. The dome’s pressing life can reach over 1 million cycles, far exceeding the industry average of 500,000 cycles, ensuring the long-term stable use of the end product.

- Q: What parameters are needed for custom dome arrays?

A: You need to provide PCB board drawings, key layout requirements, dome diameter/thickness/pressure value, installation method, usage environment (such as temperature, humidity, whether it comes into contact with liquids, etc.), order quantity, and delivery time requirements. We will provide a precise customized solution based on these parameters.

- Q: What is the minimum order quantity for bulk orders?

A: We have no strict minimum order quantity (MOQ) restrictions. We support small-batch trial production (minimum order quantity of 100 sets) and large-scale production, and can flexibly adjust according to customers’ actual needs, reducing their procurement costs and inventory pressure.

- Q: How are defective products handled?

A: If the received products have quality problems, please contact us within 7 working days after receiving the goods, providing samples of the defective products and relevant evidence. We will arrange testing immediately. After confirming that it is a production problem, we will resend the same quantity of products free of charge and bear the round-trip logistics costs; at the same time, we will initiate a quality traceability process to prevent similar problems from happening again.

- Q: Can you provide product quality certification documents?

A: Yes. Our products have passed ISO9001 quality management system certification, RoHS environmental certification, and other international standard certifications.

- Q: What if I don’t receive the goods after the delivery period?

A: If the delivery is delayed due to our reasons, we will pay liquidated damages as stipulated in the contract; at the same time, we will arrange a dedicated person to follow up on the production progress and do our best to expedite delivery.

This article focuses on dome array manufacturers in Slovenia, outlining the core pain points of the industry, selection criteria, and common questions. It recommends the top 10 dome array manufacturers in Slovenia, among which EBest Circuit (Best Technology), with its comprehensive solutions, six core advantages, and fast delivery capabilities, is a high-quality choice for dome array procurement in Slovenia.