When choosing a Metal dome array manufacturer in Spain and a Conductive film manufacturing partner in Spain, the key is not whether they are “local,” but whether they truly understand the structural logic, application scenarios, and mass production risk control of dome arrays.

Are you facing the following problems?

- Frequent modifications during the prototyping phase, with the root cause remaining unidentified.

- Dome arrays work in the sample stage, but the feel and lifespan fluctuate significantly after mass production.

- Poor coordination between the conductive film and dome structure, resulting in unstable press feedback.

- Local suppliers offer high prices but have limited investment in customization and technical support.

- Engineering problems can only be “passively repaired,” lacking proactive risk assessment.

- Once a project is expedited, delivery times become completely uncontrollable.

These are not single-process problems, but systemic risks caused by insufficient coordination in dome array design, materials, and processes.

End-to-End Process Guarantee: Our Solution

- BEST Technology’s work doesn’t start only when we “receive the drawings,” but rather from understanding the application scenario and usage frequency.

- We will clearly define the dome force range, rebound curve, conductive film matching method, array arrangement density, and assembly method before entering the prototyping and mass production stages.

Through this proactive engineering decision-making + stable mass production process model, customers in Spain can significantly reduce trial-and-error cycles and avoid the common problem of “samples working, but mass production failing.”

Why Choose Us? (Key Advantages)

- Deep understanding of dome array application scenarios

We don’t just make products; we understand the real requirements for feel and lifespan in different scenarios such as industrial control, medical equipment, and consumer electronics.

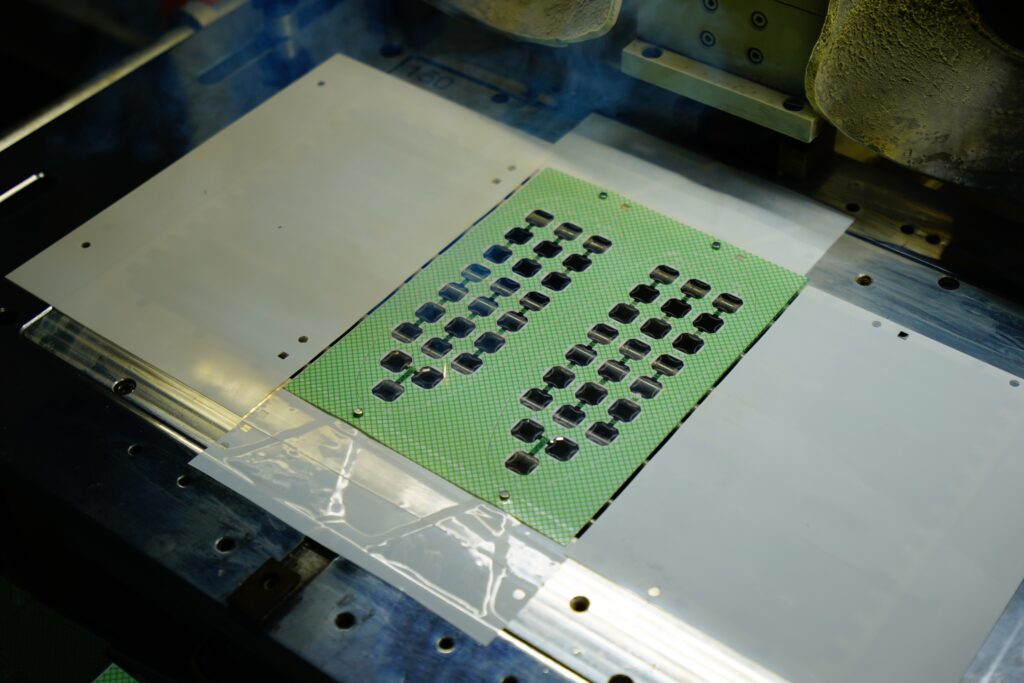

- Collaborative design capabilities for domes and conductive films

We avoid hidden problems such as unstable conductivity and delayed rebound from a structural level, rather than resorting to post-mortem fixes.

- Parametric dome management system

Each type of dome’s force value, travel, and rebound rate has clear data standards, ensuring batch consistency.

- Mass production-oriented prototyping logic

Prototyping is carried out according to mass production processes, avoiding “samples that look good but are not reproducible.”

- Supports efficient automated assembly

Provides solutions such as Tape & Reel to reduce manual assembly costs and improve overall production efficiency.

- Mature international project experience

Familiar with the actual requirements of European customers regarding documentation, compliance, and delivery stability.

The core goal of these advantages is only one: to ensure the project is successful from the first mass production run.

List of dome array manufacturers in Spain

Top 10 dome array manufacturers in Spain

| Company Name | Process Capability | Advantage |

|---|---|---|

| BEST Technology | Dome design / Array manufacturing / Conductive film | Focus on dome array, full process control |

| Ficosa | Automotive electronic components | Strong engineering capability |

| Gestamp Electronics | Industrial electronics | Stable manufacturing system |

| Jabil Spain | EMS | Large-scale manufacturing |

| Celestica Spain | EMS | Global delivery experience |

| Grupo Antolin Electronics | Automotive electronics | High-reliability applications |

| Premo Group | Electronic components | R&D oriented |

| Ikor | EMS | Multi-industry service |

| Asteelflash Spain | EMS | Batch delivery capability |

| Sisteplant | Industrial solutions | Automation capability |

How to choose a Spain dome array manufacturer?

- Do they participate in manufacturability assessments of dome force, travel, and tolerances during the design phase?

- Can they complete stress distribution and rebound consistency analysis before array layout?

- Do they use molds and materials identical to those used in mass production for prototyping?

- Do they have a clear plan for the long-term contact stability of the conductive film and dome?

- Can they provide life cycle test data instead of verbal promises?

- Do they have parameter locking and version management mechanisms in mass production?

- Do engineering changes have a traceable process, rather than temporary adjustments?

Why is BEST Technology a better choice?

Because we implement mass production-oriented decision-making mechanisms from the early stages of the project:

- For every dome array project, we lock in the dome force range, rebound curve, and tolerance window before prototyping.

- Array layout is not simply copying drawings, but rather optimizing based on pressing area, contact point position, and usage frequency.

- Prototyping uses mass-production-grade molds and materials to ensure that sample results are reproducible in mass production.

- This allows customers to avoid the typical risk of “samples passing but mass production failing” in their Spain projects.

Core Pain Points of Spain Dome Array Manufacturers

- Dome feel fluctuates significantly between different batches.

- Inconsistent rebound of different keys within the array.

- Unstable conductivity after long-term contact between the conductive film and the dome.

- Life cycle issues only become apparent after mass production.

- Engineering problems can only be repaired, not predicted in advance.

- Experience cannot be reused between different projects.

How does BEST Technology address these pain points one by one?

- Consistency issues: We control batch differences through graded management of dome parameters (force/travel/rebound rate), rather than relying on manual experience.

- Array internal differences: Local stress equalization design is performed during the layout phase to avoid different feedback between edge domes and center domes.

- Unstable conductivity issues: The conductive film is not a general selection, but rather matched and life-cycle tested based on dome material and usage frequency.

- Life cycle risk issues: Accelerated life cycle testing is completed before mass production to expose failure modes in advance, rather than dealing with them after delivery.

- Slow engineering response issues: Each project has independent engineering records, allowing problems to be quickly traced to specific parameters and process nodes.

How to evaluate the production capabilities of a Spain dome array manufacturer?

- Dome Forming Consistency Control Method

- Array Alignment Accuracy and Repeatability

- Availability of Lifetime and Tactile Testing Equipment

- Conductive Film Material Stability

- Mass Production Yield Control Method

- Availability of Parameters and Process Documents

- Ability to Support Long-Term Stable Supply

- Maintaining the Same Quality Standard During Production Expansion

How does BEST Technology meet these conditions?

- Dome forming uses a fixed parameter mold system to avoid deviations caused by manual adjustments.

- The array alignment process uses a standardized positioning method to ensure the repeatability of each array.

- All projects undergo double confirmation through lifetime testing and tactile verification.

- The conductive film comes from a long-term stable material system, not a temporary substitute.

- Each mass production project has complete process and parameter documents to support long-term reproduction and expansion.

This allows our Spanish customers to receive consistent product performance even after years of repeat purchases.

How to estimate the delivery time of a Spanish dome array manufacturer?

- Does prototyping require new mold opening?

- Are there multiple outsourced processes?

- Is the process standardized?

- Can multiple projects be processed in parallel?

- Will engineering changes require rescheduling?

- Does packaging affect the shipping schedule?

Why can BEST Technology achieve fast delivery?

- Our dome and array processes are highly standardized, eliminating the need to establish new processes for each project.

- Core processes are completed internally, reducing waiting time for outsourcing.

- Engineering and production proceed in parallel, rather than sequentially.

- Because parameters are locked in early, engineering changes do not repeatedly disrupt production schedules.

- Therefore, in custom dome array projects, BEST Technology can achieve prototype delivery in 2-3 days and maintain a stable pace during mass production.

Spain Dome Array Manufacturer Frequently Asked Questions (FAQ)

- Q: Why do samples pass but mass production fails?

A: This is usually because the design did not consider mass production tolerances and consistency.

- Q: Does the conductive film affect the tactile feel?

A: Yes, it must be designed in conjunction with the dome parameters.

- Q: Is customization always slow?

A: When the process is mature, customization does not necessarily mean delays.

- Q: How to reduce the rework rate?

A: The key lies in early engineering decisions, not end-of-line inspection.

- Q: How to ensure long-term consistency?

A: Through parametric management and standardized processes.

When evaluating the top 10 dome array manufacturers in Spain, the ability to truly reduce project risk lies in a deep understanding of dome array structure, parameters, and mass production logic; this is why BEST Technology stands out among the top 10 dome array manufacturers in Spain as a more reliable long-term partner.