What is surface mounted device?

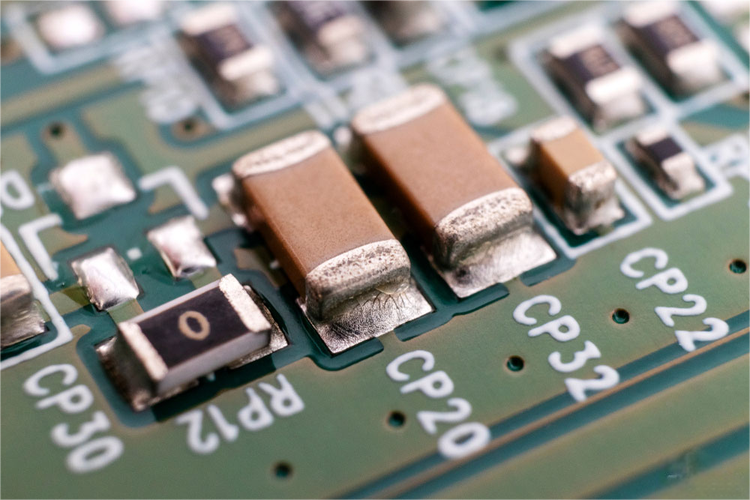

Surface mounted device (SMD) is an electronic component designed to be placed directly onto the surface of a printed circuit board (PCB). Unlike traditional through-hole components, which require leads to pass through drilled holes, SMDs use flat metal pads that attach straight to the PCB surface.

The surface mount device meaning lies in its efficiency and compactness. By eliminating the need for drilled holes, manufacturers can create boards with higher component density. This allows for smaller, lighter, and faster devices without sacrificing performance.

SMDs come in a variety of forms, including resistors, capacitors, diodes, LEDs, transistors, integrated circuits, and more specialized devices such as SMD dome switches. Each component has standardized dimensions and contacts designed for automated placement, which makes large-scale production both feasible and cost-effective.

The surface-mount devices definition focuses on two main ideas: miniaturization and direct surface attachment. With SMDs, electronics designers can achieve complex, high-performance circuits while maintaining smaller overall product sizes.

What does surface mount installation mean?

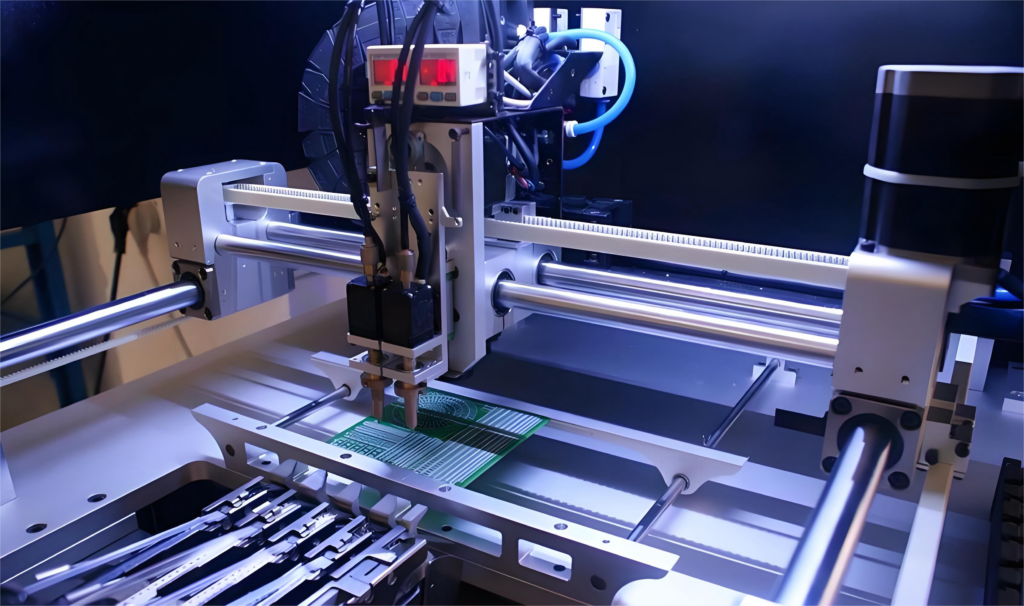

Surface mount installation is the process of attaching SMD components to a PCB using surface mount technology (SMT). It involves multiple automated steps to ensure components are placed accurately and soldered reliably.

The first step is solder paste printing, where a stencil applies solder paste precisely on the PCB pads. Next, SMD machines, also known as pick-and-place machines, carefully position each component onto the paste. Once placement is complete, the PCB enters a reflow oven. Heat melts the solder paste, creating a strong mechanical and electrical connection.

Surface mount installation allows for high-speed production. Thousands of components can be placed in minutes with precision that is impossible to achieve manually. This method also supports boards with components on both sides, further increasing circuit density.

Compared to through-hole assembly, surface mount installation is lighter, faster, and more flexible. It reduces material usage and allows for modern compact designs without compromising reliability.

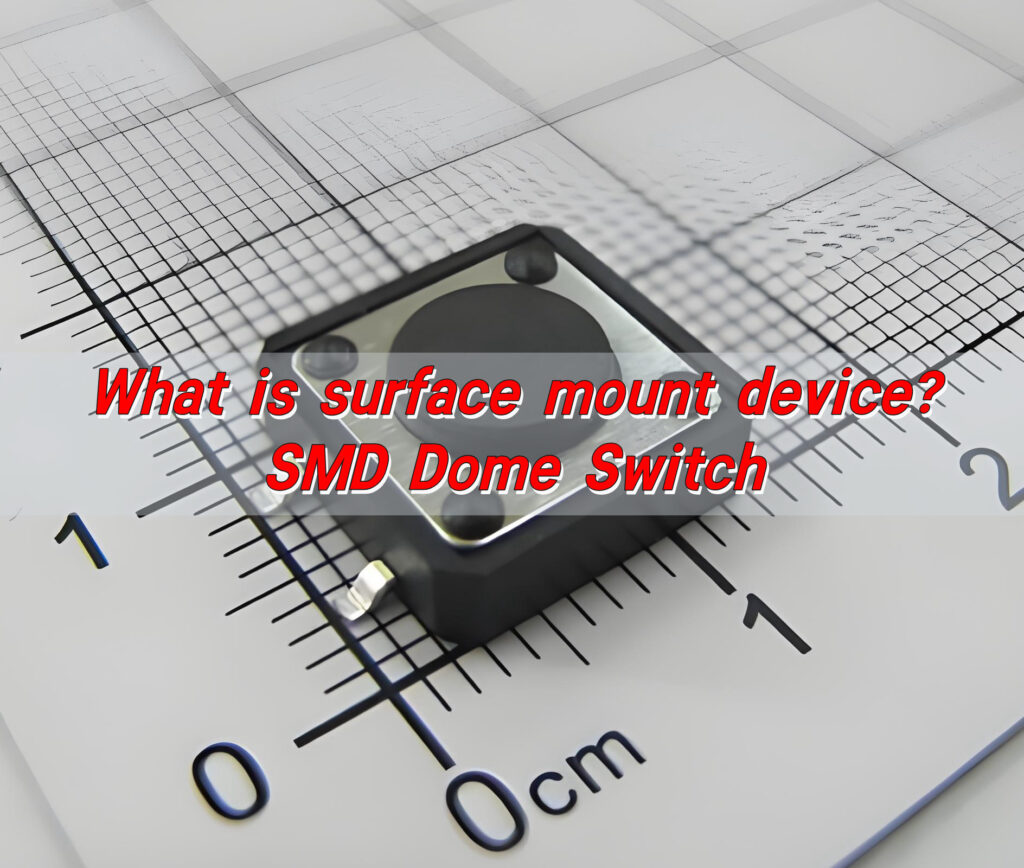

What is an SMD dome switch?

An SMD dome switch is a type of tactile switch mounted on the PCB using surface mount technology. It provides a responsive, click-like feedback when pressed, making it a preferred choice for human-machine interfaces.

Inside the switch is a metal dome that deforms under pressure. Pressing the dome closes the circuit, sending a signal to the device. Releasing the dome restores its original shape, opening the circuit. This gives users both tactile feedback and electrical functionality.

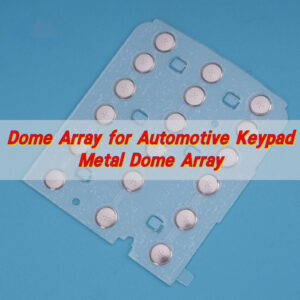

SMD dome switches are widely used in consumer electronics, automotive panels, medical devices, and industrial control systems. Their compact design allows them to fit in tight spaces while supporting automated placement alongside other surface mount components.

Unlike traditional mechanical switches, SMD dome switches can be soldered during the same reflow process as other SMDs. This reduces assembly steps and increases reliability. High-quality dome switches can withstand millions of presses, making them durable and long-lasting.

What does a surface mount do?

The primary role of a surface mount is to electrically connect components to the PCB. But beyond that, surface mount technology enables numerous advantages in design and production.

SMDs allow for smaller footprints, letting designers fit more functionality into less space. Shorter electrical paths reduce resistance and inductance, improving circuit performance and signal integrity.

Surface mount design also supports double-sided PCBs, which increases design flexibility. Components can be placed on both sides of the board without additional holes, maximizing usable space.

From a manufacturing perspective, surface mounting supports automated assembly, which ensures precision, uniformity, and repeatability. Boards can be produced faster and with fewer defects than manual soldering methods.

What are the disadvantages of surface mounting?

While surface mounting offers many advantages, it comes with a few limitations.

One challenge is manual repair and rework. Due to the small size of SMDs, replacing a component requires magnification tools and precise instruments. Handling such tiny parts can be difficult without specialized equipment.

Another consideration is mechanical strength. SMDs may not handle high stress as well as through-hole components. Connectors or components subject to physical force often require through-hole mounting for added durability.

Heat sensitivity is also a factor. Some SMD components may be sensitive to the reflow process and require careful temperature control.

Despite these drawbacks, the disadvantages are minor compared to the benefits. Proper design, assembly, and quality control ensure reliable performance in nearly all applications. The positive impact of SMDs on size, efficiency, and production speed far outweighs these few limitations.

What is an example of a surface-mounted device?

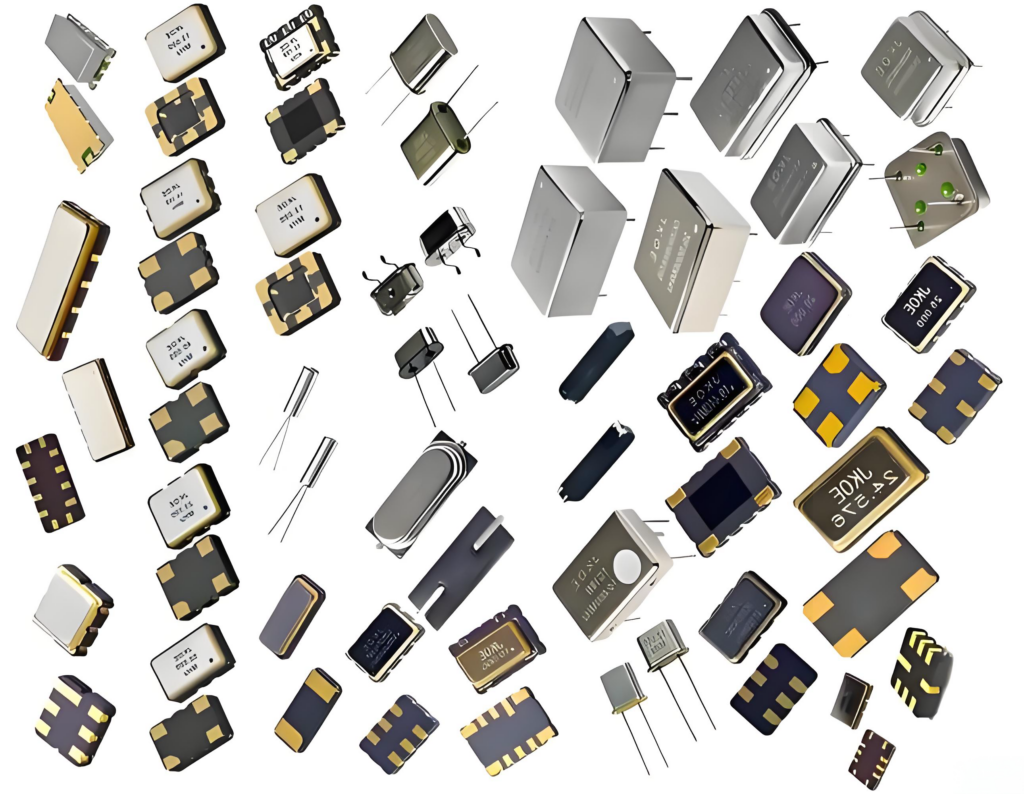

Examples of surface-mounted devices are abundant. Each SMD plays a specific role in modern electronics.

Common examples include:

- SMD resistors: tiny components that regulate current.

- SMD capacitors: store and release electrical energy.

- SMD diodes and transistors: control signal flow and power switching.

- SMD integrated circuits (ICs): contain microprocessors or memory functions.

- SMD LEDs: provide bright, compact lighting and indicators.

- SMD dome switches: offer tactile control in user interfaces.

Each component has an SMD symbol in schematics, guiding designers and assembly machines during placement.

From smartphones and laptops to car dashboards and medical devices, surface-mount devices enable products to be smaller, lighter, and more efficient.

What’s the difference between SMD and SMT?

The terms SMD and SMT are closely related but not identical.

- SMD (Surface Mount Device): refers to the actual component, such as a resistor, LED, or dome switch.

- SMT (Surface Mount Technology): refers to the process used to attach those components to the PCB.

Think of it this way: SMDs are the parts, and SMT is the method that places and solders them. SMDs cannot be efficiently mounted without SMT, and SMT has no purpose without SMDs.

SMD identifies the component, while SMT identifies how it becomes part of the circuit. Together, they form the foundation of modern PCB assembly.

Where are SMDs commonly used?

SMD components are widely used in common electronic products. Their compact size, reliability, and efficiency make them essential in various industries.

- Consumer electronics: smartphones, tablets, laptops, and wearable devices.

- Automotive electronics: dashboards, sensors, lighting, and control modules use SMDs for vibration resistance and heat tolerance.

- Medical devices: compact monitoring tools, diagnostic instruments, and portable equipment often use SMD LEDs, ICs, and dome switches.

- Industrial automation: SMDs support controllers, sensors, and communication modules in factories and production lines.

- Telecommunications: routers, 5G modules, and servers rely on high-density SMD assemblies for high-speed signal transmission.

SMDs are the invisible backbone of modern electronics. From everyday gadgets to critical industrial equipment, they provide functionality, efficiency, and compact design.

Surface mount devices (SMDs) offer functionality, efficiency, and compact design, ranging from everyday gadgets to critical industrial equipment.

Conclusion:

Surface mount devices make devices smaller, faster, and more reliable. Among them, SMD dome switches provide precise tactile feedback, compact design, and long-lasting performance.

For high-quality SMD dome switches that combine reliability and precision, contact our team at sales@metal-domes.com