At Best Technology, we don’t just manufacture metal domes—we help you create products that feel right from the first press. Our strength lies not just in products, We offer free samples, but in service.

As a trusted metal dome supplier with over 18 years of experience, we specialize in high-quality tactile metal domes that deliver precision, durability, and perfect tactile response.

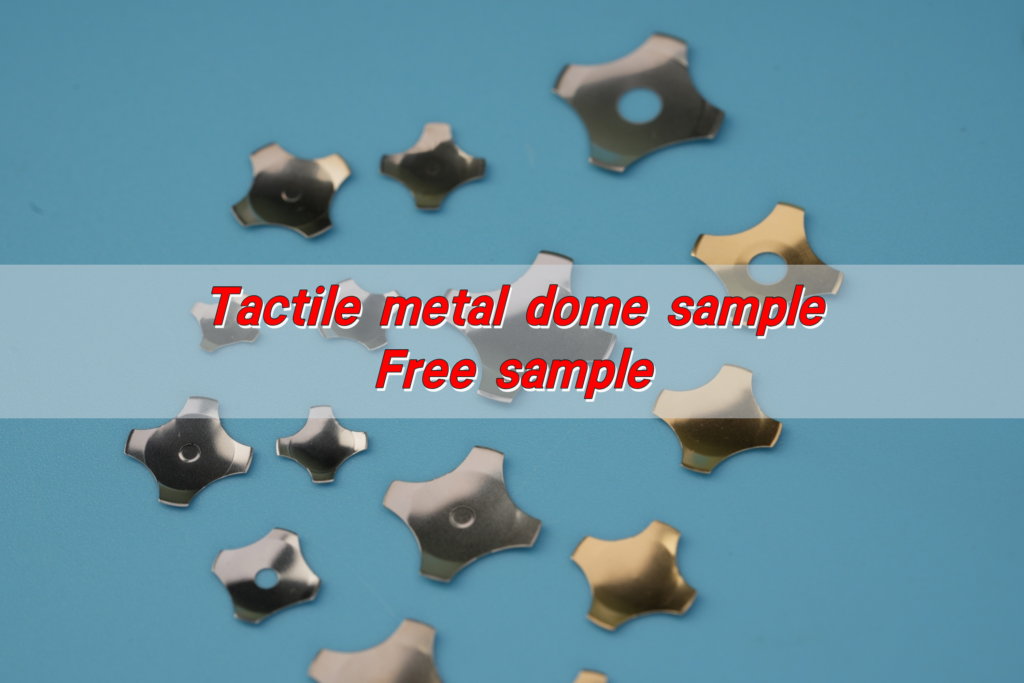

What is a tactile metal dome sample?

Tactile metal dome sample is a small test component used to check the feel and performance of metal domes before large-scale production. These domes are critical parts of membrane switches, control panels, and custom keypads. They are made of stainless steel and provide the crisp, tactile feedback users feel when pressing a button.

Samples come in various sizes, shapes, and forces to help engineers and designers verify what works best. Instead of guessing, the sample provides a real-world test that ensures the chosen dome matches the product’s needs. By using samples, you can avoid mismatched performance or customer complaints caused by poor tactile feel.

Why use a snap dome sample?

Snap dome samples allow you to physically test the button feel, response force, and click sound. Some domes are soft and silent. Others are sharp and loud.

The sample shows exactly how it performs. Whether you’re building a medical device, industrial keypad, or consumer electronics, getting the right feel is vital. A dome that’s too light may be triggered by accident. One that’s too heavy may cause user fatigue. By testing early, you avoid wrong decisions.

How to select the right metal dome?

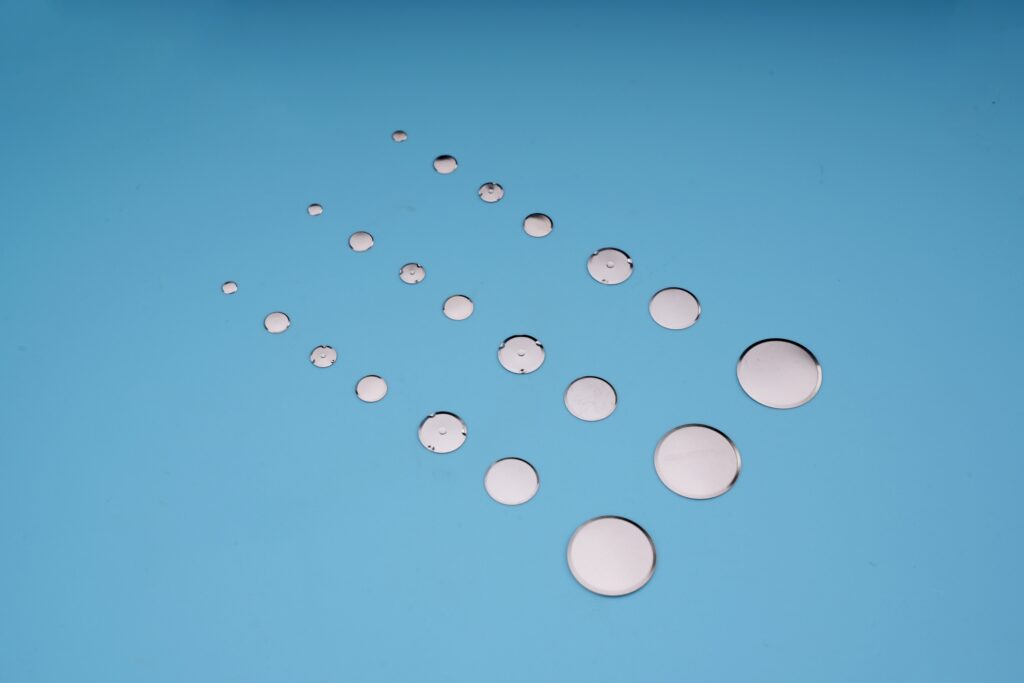

Selecting the right dome means finding the right feel. The actuation force matters most. Common options range from 180g to 520g. A lower force feels soft, suitable for light-touch applications. A higher force delivers firm feedback, perfect for outdoor or glove-use devices.

Next is the dome shape. Four-leg domes are the most stable and widely used. Round domes offer softer actuation. Triangle domes save space. Oblong domes are good for narrow button layouts.

You also want to look at the click ratio. A higher ratio means a sharper, louder click. Lower ratios give smoother, quieter presses.

Dome size also impacts height and tactile feel. A larger dome feels broader. A smaller one feels faster.

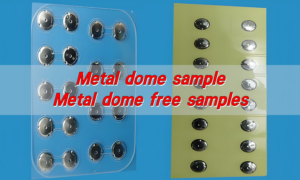

Why test dome arrays before mass use?

Dome arrays are sheets of domes mounted on PET film. They represent how the domes will function in your final product. Testing the array helps identify problems early. You can check if the alignment is correct. You can feel if all buttons give equal response.

Samples let you test layout spacing, sheet thickness, and assembly fit. They also allow signal testing on actual circuits. Without testing, you risk getting hundreds of faulty units. Reworking these later adds time and cost.

Dome array sample can simulate the real usage experience. It lets you validate function and feel under pressure.

Can samples be custom-made?

Yes, they can. Every product is different. That’s why dome samples are available in custom specifications. If you need a 360g force, 10mm four-leg dome, we can make it.

If you want a softer, quiet dome for a hospital keypad, we’ll match that too. You can also customize dome layout, PET size, adhesive type, and overall sheet structure.

For fast machine assembly, domes can be packed in tape & reel. You can request domes mounted on your layout drawing. The goal is to let you test the exact performance, not a generic sample.

Custom dome samples reflect your product’s final look and feel. You get accurate feedback and real-time user experience.

How do dome samples aid testing?

They give instant answers. You can measure press force, check for bounce, and confirm actuation signal. Connect it to your circuit and test how fast the dome responds.

Some domes may trigger too easily. Others may feel sluggish. The sample exposes these flaws early.

You also test durability. Press the dome a thousand times. See if the click remains consistent. You can spot sticking points, misfires, or uneven feedback. Testing gives you data. You avoid tooling errors and reduce the risk of product failure.

Conclusion:

Tactile metal dome samples help you test feel, force, sound, and layout before mass production. With free or custom samples available, you can test, compare, and improve faster. Whether it’s a single dome or full dome array, using a sample early saves time, cost, and stress.

Contact us now at sales@metal-domes.com for your free tactile metal dome sample.