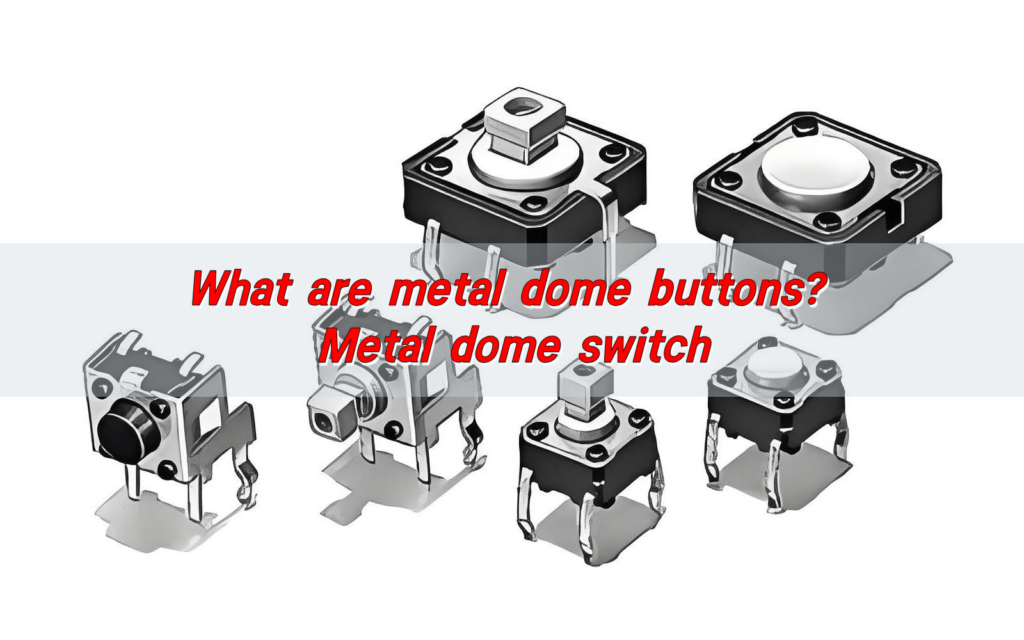

Metal dome buttons are switches that use the elastic deformation of metal domes to switch the circuit on and off. The core is the metal dome. When the button is pressed, the dome is deformed by pressure and contacts the circuit to conduct; when released, it returns to its original shape and the circuit is disconnected. Metal dome switches provide precise tactile feedback and high durability, and are widely used in membrane switches, PCB circuit boards, home appliances and electronic equipment.

What is a dome switch button?

Dome switch button is a type of mechanical switch that uses a dome-shaped metal disc to open or close an electrical circuit. When you press it, the dome flexes and makes contact with a conductive surface underneath. That simple movement sends a signal to the device.

When the pressure is released, the dome returns to its original shape. This quick snap creates a sharp tactile click. Dome switch buttons are often used in interfaces where feedback matters, like remote controls, keyboards, or industrial equipment. The snap sound and feel improve both usability and accuracy.

How to make a metal dome?

Metal domes are made using high-precision stamping or laser forming techniques. First, thin sheets of stainless steel, often SUS301, are prepared. Then they are stamped or laser-cut into dome shapes with careful control over thickness and curvature.

Every tiny detail matters. The dome’s size, height, and force rating are designed to deliver a specific response. If even one part is off, it can affect the whole device’s performance.

Some domes are also plated with gold or nickel to improve conductivity. Others get black oxide treatment to change their appearance and enhance durability. Every process is tuned for high quality and reliability.

Are metal dome buttons tactile?

Yes, they are extremely tactile. Tactile feedback means you can feel and hear when the button has been pressed. Metal dome buttons are designed to offer a crisp snap. This snap is both mechanical and sensory.

The feel is consistent across uses. That’s why tactile metal dome switches are used in medical panels, keypads, and handheld controls. They offer a sense of control that touchscreen-only devices can’t provide.

What are the benefits of metal dome buttons?

The advantages of metal dome buttons are powerful. First, they deliver excellent tactile response. The user instantly knows the switch has been activated.

They are also reliable. Domes are built to withstand millions of presses without losing performance. That makes them ideal for long-term applications like remote controls and keypads.

Their compact size is another major plus. They allow for slim and modern device designs. Even in small spaces, they work perfectly.

Another key benefit is their clean construction. Domes are usually sealed in layers, which keeps dirt and moisture out. This leads to higher reliability in tough conditions.

They’re customizable too. You can select the force, shape, size, and coating to suit your specific needs. Whether you need a soft touch or a strong snap, there’s a dome for that.

Finally, they are cost-effective. Despite their precision, they are affordable for large-scale production. That’s why you see them across consumer electronics, medical tools, and even aerospace systems.

What materials are metal dome buttons made of?

Most metal domes are made from SUS301 stainless steel. This material is chosen for its strength, flexibility, and ability to return to shape after each press. It’s corrosion-resistant and performs well in tough environments.

Some dome types are also plated. Nickel plating adds durability and helps conductivity. Gold plating, used in some sensitive applications, boosts performance and reduces resistance.

For specific design needs, black metal dome buttons are also available. These are domes treated with black oxide or other coatings. This changes their appearance while increasing oxidation resistance.

All these materials are chosen to improve function, extend life, and meet industry demands. From the inside out, each dome is built to deliver results.

Do metal dome buttons have a long lifespan?

Yes, they have an impressively long lifespan. Metal dome buttons can endure over one million presses—some even more. The secret lies in their snap design. When the dome is pressed, it flexes and snaps back, without warping or bending out of shape.

The materials used, especially stainless steel, are meant to handle repetitive stress. The dome doesn’t wear out quickly. It keeps giving the same sharp click even after years of use.

In sealed designs, dust and moisture can’t reach the contacts. This adds extra protection and extends life. Unlike other switches that may degrade or fail, metal domes are stable and consistent over time.

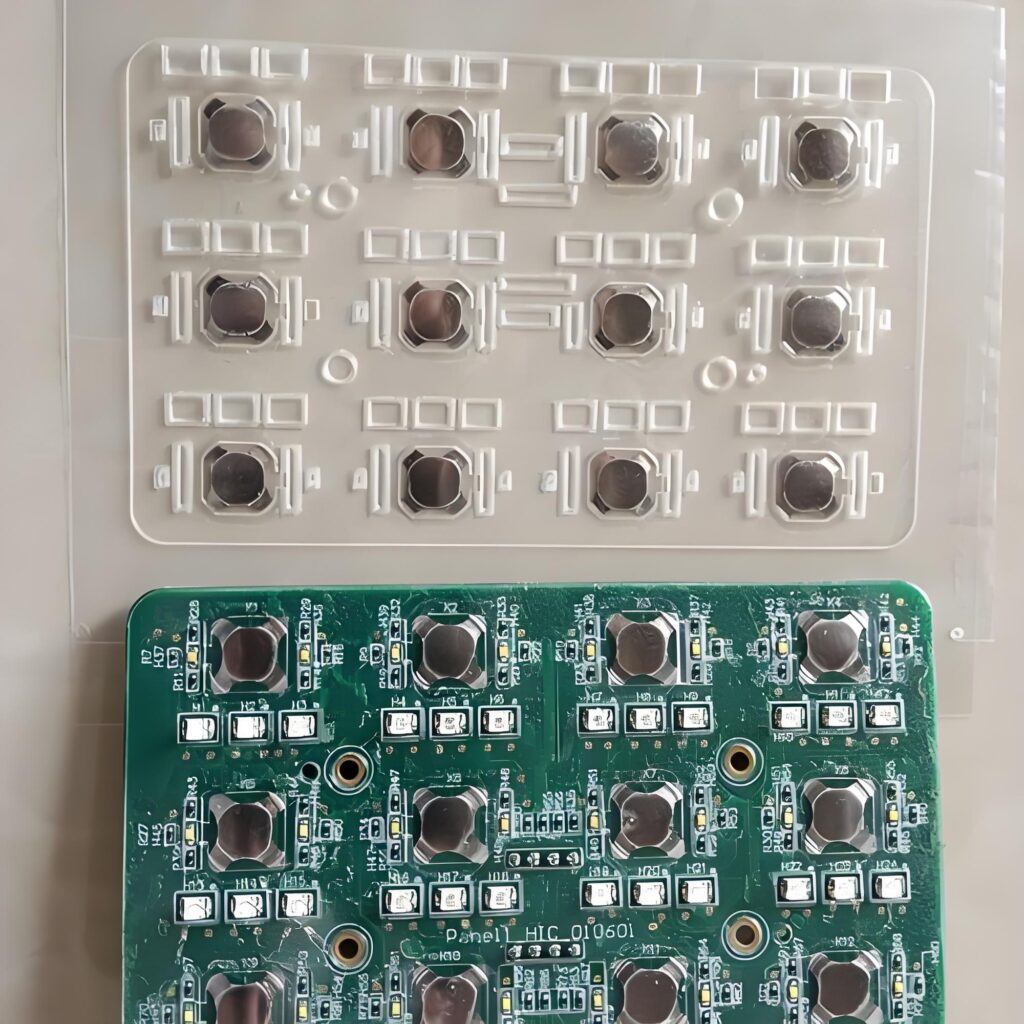

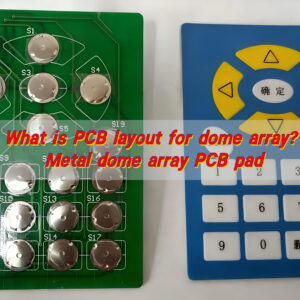

How do metal dome switches work?

When you press the metal dome, it collapses downward and connects with a conductive layer beneath. This contact completes the circuit. A signal is sent, and the action is registered.

When you release the button, the dome returns to its original shape, breaking the connection. This reset action is fast, reliable, and repeatable.

Dome switches are typically placed inside a layered structure. These layers often include a top graphic layer, an adhesive spacer, a printed circuit, and the dome itself.

The structure is thin, clean, and easy to assemble. And because there are no bulky moving parts, the system stays efficient and lightweight.

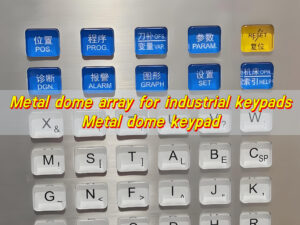

Where are metal dome push buttons used?

In consumer electronics, they appear in mobile phones, game controllers, and remote controls. Their small size and satisfying feel make them a favorite.

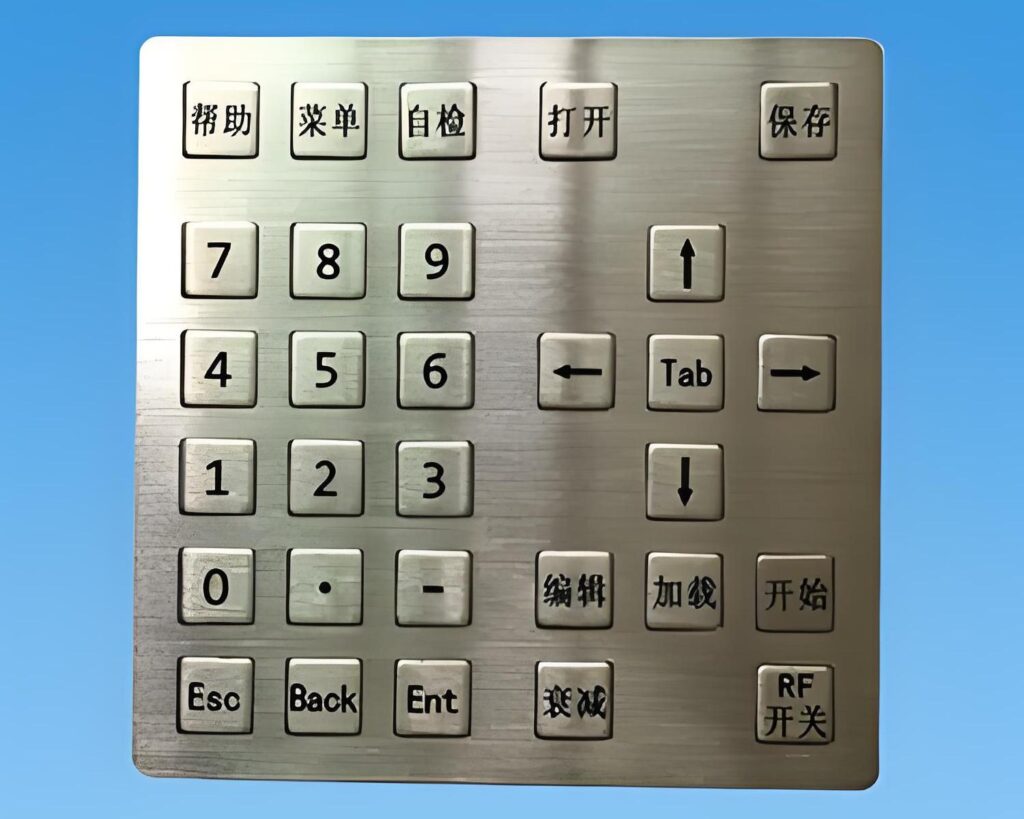

In industrial environments, you’ll find them on control panels and handheld testers. Here, their durability and resistance to dust make them ideal.

In medical devices, dome switches ensure precise input where every touch matters. The tactile feedback helps avoid mistakes in critical settings.

In automotive dashboards, they control lights, air, and entertainment systems. Even in tough climates, they keep working.

Security systems and access control panels also use them. They respond instantly and don’t wear out like rubber or silicone buttons.

What are black metal dome buttons for?

Black metal dome buttons are designed for special applications. They’re often used when appearance matters just as much as performance.

The black finish comes from oxide treatment or black plating. This doesn’t just look sleek—it adds a layer of protection too.

They are used in high-end electronics, luxury remote controls, and designer interfaces. The matte black color reduces light reflection, making them ideal for control rooms and displays.

They also resist wear better. The finish protects the surface from scratches and helps maintain the button’s appearance over time.

Conclusion:

Metal dome buttons are small, but they bring big benefits. They offer crisp tactile response, long lifespan, and powerful durability. From everyday gadgets to high-end machinery, these dome switches improve control, comfort, and reliability.

For custom solutions or more information, contact us at sales@metal-domes.com