How to make a membrane switch? The production of membrane switches involves key steps such as design, material selection, printing and assembly, which require precise operation to ensure its function and performance. Metal dome switches can be used as an upgrade option for membrane switches. They provide tactile feedback through the elastic deformation of metal domes, enhance the operating experience, and are suitable for devices that require clear button feedback.

What is a membrane switch?

A membrane switch is a low-profile electrical switch that activates or deactivates a circuit when pressed. It doesn’t use traditional mechanical parts like springs or metal levers. Instead, it relies on layers of flexible materials.

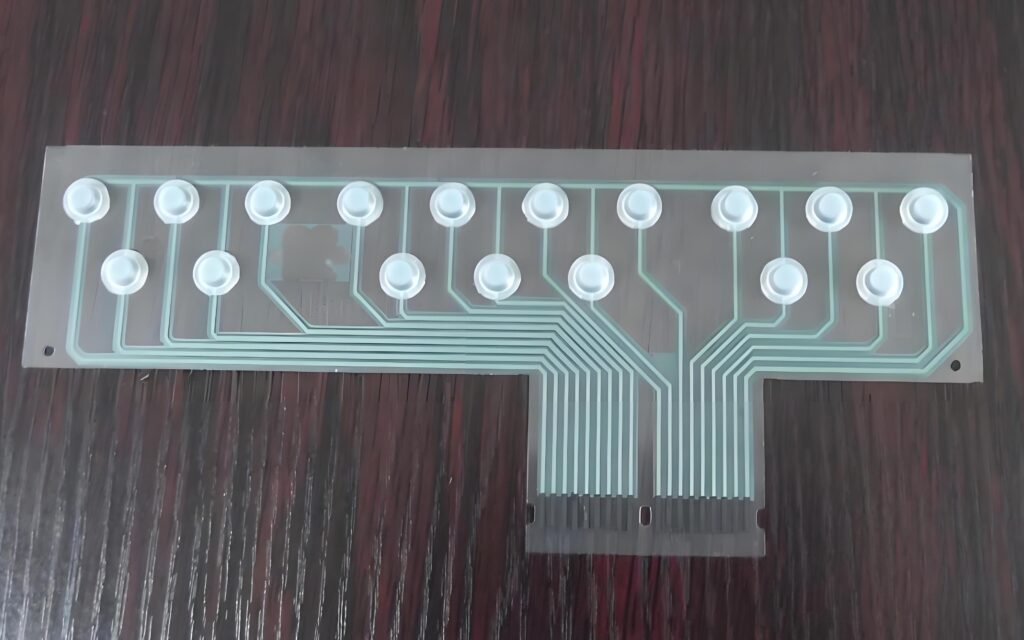

Most commonly, it has four layers:Graphic overlay (the outer layer you press)?Spacer?Circuit layer?Rear adhesive. Each time you touch it, you complete a circuit. That’s how a command is sent.

Unlike bulky mechanical switches, membrane switches are slim, smooth, and sealed. They’re easy to clean and built for tough environments.

How are membrane switches made?

Once the design is approved, here’s what follows:

- Printing the circuit layer – This is usually done on polyester (PET) using conductive inks like silver or carbon.

- Laminating the spacer – This layer ensures the top and bottom circuits don’t touch unless pressed.

- Attaching the graphic overlay – This is the face of the keypad. It shows the symbols or icons.

- Adding tactile domes – If tactile feedback is needed, small metal or polyurethane domes are placed beneath the overlay.

- Finishing and testing – The assembled switch is cut to size, inspected, and tested for accuracy.

This layered build gives membrane switches their strength and flexibility. The quality of each layer matters.

What are the different types of membrane switches?

Membrane switches aren’t all the same. There are different types. Choosing the right one depends on your application.

- Non-tactile membrane switches – These offer no physical feedback. They’re silent and sleek. Perfect for flat surfaces.

- Tactile membrane switches – These use metal domes or embossed designs to give you a ‘click’ feeling.

- Backlit membrane switches – Ideal for dark environments. They use LEDs or light guides to illuminate keys.

- Capacitive membrane switches – Activated by touch, not pressure. Smooth and modern, like your smartphone.

- Waterproof membrane switches – Sealed for harsh conditions. Used in outdoor and medical environments.

How to design a membrane keypad?

Designing a membrane keypad isn’t just about looks—it’s about function. You want it to feel good under your fingers, respond instantly, and last through thousands of touches.

Decide on tactile or non-tactile. Tactile domes offer that satisfying click. Non-tactile is more subtle.

Choose materials wisely. The overlay material affects feel and durability. Polyester offers better chemical resistance than polycarbonate.

Design the graphics. Use high-contrast colors. Make labels clear and intuitive. Avoid visual clutter.

Plan the circuit layout. Routes should be short and efficient. Use shielding if electromagnetic interference is a concern.

Think about lighting. If backlighting is needed, plan for LEDs, light guides, or fiber optics.

Test and refine. Always prototype. Test for feel, speed, and lifespan. Make improvements before final production.

How to make membrane keypad?

- Create the design files – Use software like AutoCAD or Altium. Include layers for graphics, circuit, and tactile elements.

- Print the circuit – Use screen printing or digital printing to lay down conductive traces.

- Prepare the overlay – Print the top layer using durable inks on PET or polycarbonate.

- Apply the spacer – Cut precise holes for keys to flex. Stick it between the overlay and the circuit.

- Add tactile domes (if needed) – Place domes in exact positions under key areas.

- Lamination – Carefully layer all components using heat or pressure.

- Attach connectors – Flat flex cables or ZIF connectors are common.

- Test the keypad – Check for responsiveness, accuracy, and electrical performance.

How to make a membrane keyboard more responsive?

Here’s how to boost it:

- Use high-quality tactile domes – They offer crisp feedback and better rebound.

- Adjust the actuation force – Make it lighter or heavier based on user preference.

- Choose better overlay materials – Thinner overlays can make the switch more sensitive.

- Reduce key travel distance – Less movement means faster response.

- Optimize spacer thickness – Too thick, and the response slows down. Too thin, and it might short.

What is the advantage of membrane switch?

Simplicity. Durability. Clean design. These switches have no exposed parts, so they resist dirt and moisture. They’re sealed. That makes them perfect for medical devices, kitchen appliances, and outdoor gear.

They’re thin and light. Great for compact devices. They can be made flexible, curved, or even transparent.

And they’re affordable. Mass production is efficient, bringing down cost without sacrificing quality. When designed right, they last millions of presses.

How do membrane switches work?

When you press a key, the top circuit layer flexes down. It touches the bottom layer, closing the circuit. Electricity flows, and the signal is sent. Once you release the pressure, the spacer pushes the top layer back up. The circuit opens again.

In tactile designs, metal domes give feedback. You feel the “click.” In backlit designs, LEDs shine through the layers to guide your touch.

What are the applications of membrane switch?

Membrane switches are everywhere. Their applications stretch across industries.

- Medical equipment – Smooth and sealed for hygiene. Perfect for hospitals and labs.

- Industrial control panels – Withstand vibration, chemicals, and temperature shifts.

- Consumer electronics – Remote controls, microwaves, washing machines.

- Fitness machines – Durable under sweat and pressure.

- Automotive interfaces – Sleek dashboards and control buttons.

Wherever precision and durability are needed, you’ll find them.

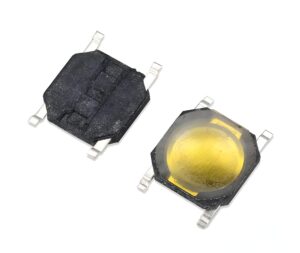

What is the difference between membrane and dome switch?

A membrane switch is a complete system. It uses flexible layers and circuits to register input. It may include tactile domes or not.

A dome switch, on the other hand, refers specifically to the metal or rubber dome that gives tactile feedback. It’s a component inside a membrane or mechanical switch.

So, dome switches are part of some membrane switches—but not all. Think of the dome as an upgrade to the feel and performance.

If your device needs feedback—go for tactile dome switches. If you want a flat, silent surface—choose non-tactile membrane.

Conclusion:

Membrane switches might look flat, but they pack a powerful punch. With thoughtful membrane keypad design, they become reliable, responsive, and ready for anything.

Still have questions? Want to explore custom solutions for your business? Reach out to us at sales@metal-domes.com