Marine grade switches are specialized components designed to survive in the harsh, corrosive, and demanding environments encountered on boats and other marine vessels. This article explores the essential types, performance criteria, and selection guidelines for these critical components to ensure reliable operation in modern marine electrical systems.

At EBest Circuit (Best Technology), we specialize in precision metal dome technology, a core element in high-performance tactile switches. Our expertise enables superior marine grade push button switches that deliver consistent tactile feedback, long-cycle reliability, and robust environmental sealing. All metal dome, PCB, and SMT production lines operate under a fully integrated MES system, ensuring full traceability and strict process control. With certified manufacturing capabilities for both medical and aerospace applications, we provide engineering-level assurance for projects requiring exceptional quality and reliability. For bespoke metal dome fabrication or metal dome assembly solutions, please contact our engineering team at sales@metal-domes.com.

What Are Marine Grade Switches?

Marine grade switches are electrical controls engineered specifically to withstand the unique challenges of the marine environment, including constant exposure to saltwater spray, humidity, UV radiation, and corrosive salt-laden air. Unlike standard automotive or industrial switches, they incorporate specialized seals, corrosion-resistant materials, and robust construction.

Key Defining Features

- Environmental Sealing — Achieve high IP ratings (IP66, IP67, IP68) to prevent water and dust intrusion.

- Corrosion Resistance — Built from stainless steel, marine-grade polymers, or plated brass to resist galvanic and salt corrosion.

- Durability — Designed to withstand vibration, shock, and frequent operation on boats.

- Safety Compliance — Often engineered to meet ignition-protection and marine electrical safety standards.

Marine grade electrical switches are the cornerstone of a safe and dependable boat electrical system, preventing failures that could lead to system malfunction or safety hazards.

What Are the Key Types of Marine Grade Rocker Switches?

Rocker switches are among the most common and versatile controls on modern boats. Understanding their variations is key to proper system design, and they are a primary component in a well-organized marine grade rocker switch panel.

Common Classifications

- Circuit Function — SPST for basic on/off, SPDT for selecting between two circuits.

- Actuation Type — Momentary for spring-return actions (trim, starter), maintained for general equipment control.

- Configuration — On/Off, On/On, and multi-position options such as On/Off/On.

Selecting the correct type, such as compact marine grade rocker switches for tight panels or momentary versions for specific actions, ensures intuitive and reliable control.

What Defines the Performance of Marine Grade Rocker Switches?

The performance of these switches is determined by rigorous criteria that go beyond simple appearance. For the best marine grade switches, these parameters are essential.

Critical Performance Metrics

- IP Rating — Determines water and dust resistance; IP67 protects against temporary immersion, IP68 against prolonged submersion.

- Material & Finish — UV-resistant housings and gold-plated or silver-nickel terminals maintain long-term electrical integrity.

- Electrical Rating — Must exceed the load’s maximum current and voltage with a margin for safety.

- Mechanical Life — High-grade switches offer tens of thousands to millions of cycles.

High-quality construction, material science, and strict testing standards define the true performance of marine-ready rocker switches.

How Do Waterproof Marine Switches Resist Moisture and Salt Exposure?

The waterproof capability of marine switches is engineered through deliberate sealing and protection strategies.

Primary Resistance Mechanisms

- Multi-Layer Sealing — Silicone gaskets, rear panel seals, and internal actuator seals.

- Corrosion-Inhibiting Materials — Stainless steel components, dielectric-greased terminals, and UV-stable plastics.

- Sealed Terminations — Fully insulated terminals prevent salt creep and moisture intrusion.

This layered protection is what separates true waterproof marine switches from non-marine alternatives.

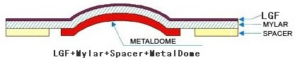

Why Are Marine Grade Push Button Switches Well-Suited for Metal Dome Technology?

Marine grade push button switches benefit greatly from metal dome technology, especially in high-use or safety-critical functions.

Synergistic Advantages

- Superior Tactile Feedback — Crisp, consistent “click” sensation, even with gloves or in rough seas.

- Excellent Sealing Potential — Dome assemblies integrate easily behind sealed rubber or silicone membranes.

- High Durability — Rated for millions of cycles with stable electrical performance and corrosion resistance.

This makes EBest Circuit’s metal dome technology ideal for custom marine push button switch panels requiring tactile precision and robust sealing.

When Should Marine Toggle Switches Be Used in Boat Electrical Systems?

Marine toggle switches offer unique advantages in specific scenarios aboard boats.

Ideal Application Scenarios

- High-Voltage or High-Current Circuits — Suitable for heavy-duty loads like windlass or main power feeds.

- Clear Positional Indication — Lever position offers unmistakable ON/OFF status.

- Vibration-Prone Areas — Robust detent construction resists accidental switching.

Toggle switches remain ideal for tasks requiring ruggedness and absolute clarity.

How Does a Marine Grade Switch Panel Improve On-Board Control?

A marine grade switch panel serves as a centralized control station, elevating the operability and safety of the vessel.

Key Improvements

- Centralized Organization — All controls grouped ergonomically in one location.

- Simplified Wiring — Fewer wire runs, integrated bus bars, and fewer failure points.

- Enhanced Safety — Built-in circuit protection and waterproof interfaces with clear labeling and lighting.

A well-designed switch panel significantly modernizes and stabilizes boat systems.

What Failure Modes Commonly Affect Marine Grade Electrical Switches?

Understanding typical failure modes enables better prevention and selection.

Primary Failure Mechanisms

- Terminal or Contact Corrosion — Due to poor seals or unprotected terminations.

- Seal or Gasket Degradation — UV exposure and temperature cycles damage sealing materials.

- Internal Contact Wear — Caused by switching inductive loads without proper ratings.

- Mechanical Breakage — Excessive vibration, force, or exceeding cycle life.

Quality component selection and proper installation dramatically reduce these risks.

How to Select the Best Marine Grade Switches for Boats?

Proper selection ensures long-term reliability in marine environments.

Selection Checklist

- Evaluate Environment — Define required IP rating and UV-resistant materials.

- Verify Certifications — ABYC, ISO, or NMEA compliance where applicable.

- Match Electrical Ratings — Use a switch rated at least 150% above the load.

- Choose Actuator Type — Rocker, toggle, or push-button based on function.

- Inspect Construction Quality — Focus on sealing design, plating, and housing.

Following these guidelines ensures dependable operation in demanding marine systems.

To sum up, marine grade switches are essential components that deliver control, safety, and reliability in harsh marine environments. This guide has outlined their types, standards, and selection criteria to support informed decisions.

For applications demanding exceptional tactile reliability and sealing—especially in marine grade push button switches—precision metal dome technology is the key. EBest Circuit (Best Technology) offers deep expertise to help manufacturers develop switches that exceed marine durability and performance expectations. For technical support or custom metal domes solutions, pls feel free to contact us at sales@metal-domes.com.