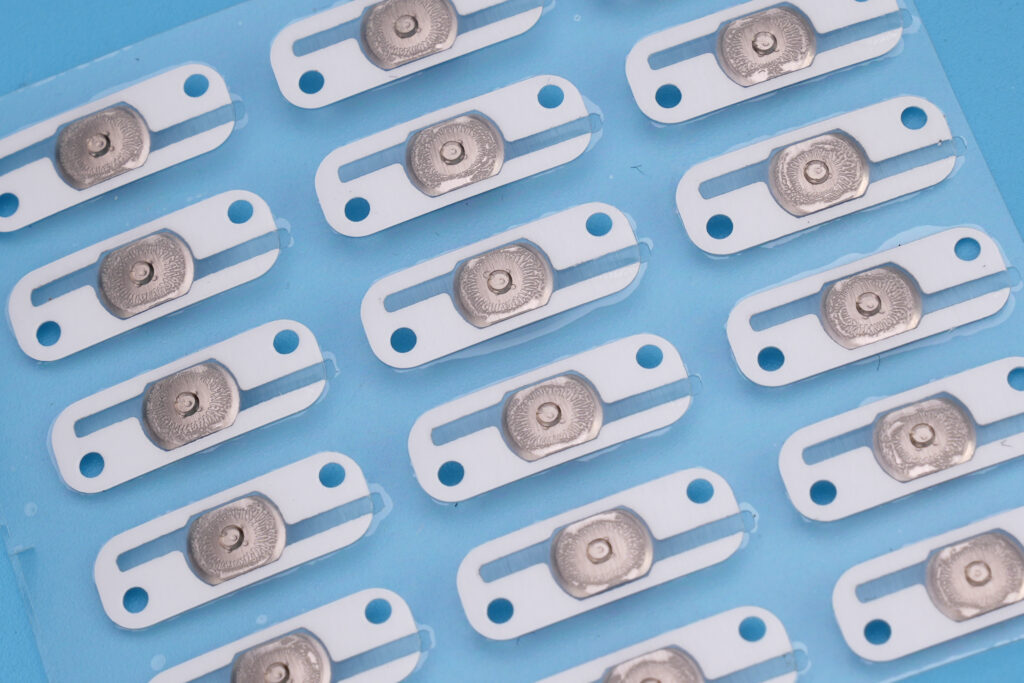

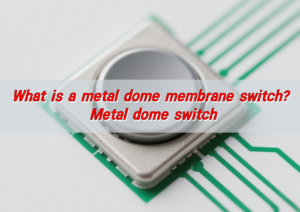

Dome Array Manufacturers in Lithuania are gaining attention as demand grows for reliable tactile switch solutions in industrial control, medical devices, and consumer electronics.

Are you facing the following problems?

- Long prototyping cycles and repeated revisions: Local suppliers lack a deep understanding of dome force, rebound curves, and other parameters, often requiring multiple sample adjustments, severely delaying project progress.

- Disconnection between design and manufacturing: The dome array design phase lacks manufacturability assessment, leading to poor fit and inconsistent tactile feel during mass production.

- Inconsistent consistency and unstable lifespan: Different batches of dome arrays have noticeable differences in feel, and insufficient lifespan test data poses potential after-sales risks.

- Uncontrollable delivery cycles: Small batch orders are repeatedly delayed, and there is a lack of rapid response capabilities for urgent projects.

- Insufficient technical support: When problems arise, the solution is often limited to “remaking a batch,” rather than fundamentally addressing the issue from a structural, material, and process perspective.

End-to-End Process Guarantee from Demand to Delivery

As a professional dome array manufacturer, EBest Circuit (Best Technology) helps customers reduce risks and improve efficiency through end-to-end control of the design, prototyping, mass production, and delivery process:

- Involvement in dome structure and tactile design from the initial project stage

- Simultaneous lifespan, rebound, and tactile consistency testing during the prototyping phase

- Completion of DFM/DFA manufacturability verification before mass production

- Provision of stable batch management and rapid replenishment capabilities during the delivery phase

This is not just manufacturing capability, but an engineering system that takes responsibility for the delivery results.

Why choose us? EBest Circuit (Best Technology) Core advantages

- 20+ years of focused experience in dome arrays: Deep understanding of high-reliability applications in industrial control, medical, and automotive electronics.

- High-consistency manufacturing capabilities: Dome force, tolerances, and rebound curves are fully controlled, and batch stability is significantly better than the industry average.

- Fast prototyping and technical response: Fast sample delivery, and solutions to engineering problems provided within 48 hours.

- Scalable mass production and cost advantages: China + Vietnam manufacturing system, balancing stable quality and cost control.

- International compliance and complete documentation: Provides complete technical documentation such as ROHS/REACH, facilitating export and certification.

Top 10 Dome Array Manufacturers in Lithuania

| Company Name | Process Capability | Advantage |

|---|---|---|

| EBest Circuit (Best Technology) | High-precision dome array prototyping, small-batch customization, mass production; Supports various materials (silicone, rubber, etc.) and custom specifications; Integrated SMT assembly services | Leading technology, high product yield; Fast delivery (2-3 days); Full-process customization service; Comprehensive after-sales service system; Good industry reputation |

| Lithuania Precision Electronics Co., Ltd. | Mass production of standard dome arrays; Supports simple customization; Basic inspection capabilities | Local production, rapid response; Significant cost advantage for bulk orders; Streamlined cooperation process |

| Baltic Dome Tech | Medium-high precision dome array prototyping and production; Supports some special material customization; Basic SMT supporting services | Professional technical team; Strong product adaptability; Convenient regional logistics |

| Vilnius Electronic Components Manufacturing | Mass production of standard dome arrays; Simple prototyping services; Basic quality inspection | Rich production experience; High supply stability; Cost-effective |

| Kaunas Advanced Dome Solutions | High-precision dome array customization; Complex structure product development; Supporting design services | Strong R&D capability; High degree of customization; Good compatibility for high-end products |

| Lithuania Microelectronic Tech | Small-batch dome array prototyping; Standard specification mass production; Diverse material options | Short prototyping cycle; High cost-performance ratio; Excellent service attitude |

| Sigulda Electronic Manufacturing Group | Large-volume dome array production; Standardized production; Basic customization services | Large production scale; Strong supply capacity; Preferential policies for long-term cooperation |

| Taurage Precision Components Co. | Medium-precision dome array prototyping and production; Supports conventional material customization; Independent inspection laboratory | Strict quality control; High product consistency; Timely technical support |

| Klaipeda Electronic Dome Manufacturing | Mass production of standard dome arrays; Simple prototyping; Supporting logistics services | Port logistics advantage; High delivery efficiency; Low cooperation threshold |

| Panevezys Tech Components Ltd. | Small-batch dome array customization; Conventional mass production; Basic technical transformation services | High flexibility; Adapts to SME needs; Flexible payment methods |

How to choose a Lithuania Dome Array manufacturer?

- Does the manufacturer have integrated Dome design and manufacturing capabilities?

- Does it provide quantifiable lifespan and tactile feel test data?

- Can it identify and mitigate mass production risks during the prototyping phase?

- Does it have a batch consistency control system?

- Can it support fast delivery and urgent orders?

- Does it have experience serving international clients for a long time?

Why is EBest Circuit (Best Technology) the best choice?

We not only meet all the above conditions, but also ensure that every batch of Dome Arrays is “predictable, reproducible, and deliverable” through upfront engineering, data-driven manufacturing, and scaled production lines.

Core Pain Points of Lithuania Dome Array Manufacturers

- Lack of engineering verification in the design phase —> We integrate DFM (Design for Manufacturability) in the design phase.

- Poor batch consistency —> Full process force and tolerance control.

- Insufficient lifespan data —> Stable lifespan verification of over one million cycles.

- Unstable delivery times —> Standardized production lines + rapid production scheduling.

- High communication costs —> Direct communication with a professional engineering team.

- Costs fluctuate with order volume —> Scaled manufacturing locks in long-term costs.

How to analyze the production capacity of a Lithuania Dome Array manufacturer?

Does it have independent Dome stamping and forming capabilities?

Does it have Array alignment and bonding precision control?

Does it have batch traceability and quality records?

Does it support multi-structure, multi-specification Domes?

Can it maintain stable mass production in the long term?

Is it ISO quality system certified?

Does it have international project experience?

EBest Circuit (Best Technology) has a mature system in all the above dimensions and has achieved long-term stable supply for clients in multiple countries.

How to evaluate the delivery time of a Lithuania Dome Array manufacturer?

- Is prototyping standardized?

- Is there a safety stock mechanism?

- Is the production line flexible and adjustable?

- Does it support urgent orders?

- Is there a clear delivery time commitment?

- Can it shorten the communication and confirmation cycle?

EBest Circuit (Best Technology), relying on its mature production lines, can achieve fast sample delivery in 2-3 days, significantly shortening the customer’s project cycle.

Frequently Asked Questions (FAQ) about Lithuania Dome Array Manufacturers

- Q1: Why is there a large difference in tactile feel between batches of Dome Arrays?

A: This usually stems from insufficient process control; we solve this through full-process parameter locking.

- Q2: Why are prototypes always repeatedly modified?

A: Lack of upfront engineering verification; we complete manufacturability assessment in the design phase.

- Q3: Are small batch orders neglected?

A: At EBest Circuit (Best Technology), even small batches follow standard procedures, ensuring consistent quality.

- Q4: How do you ensure stable long-term supply?

A: This is achieved through multiple production lines and standardized management.

If you are looking for a partner among the top 10 dome array manufacturers in Lithuania that truly possesses engineering capabilities and delivery guarantees, EBest Circuit (Best Technology) is a trustworthy long-term choice and one of the few professional manufacturers among the top 10 dome array manufacturers in Lithuania that can simultaneously address design, manufacturing, and delivery issues.