Dome Array Manufacturers in Denmark support a wide range of high-reliability applications across the country’s electronics, medical, and industrial sectors. Danish OEMs rely on dome arrays that deliver consistent tactile feedback, stable actuation force, and long operational life, particularly in control panels, medical devices, and communication equipment where precision and durability are critical.

Are you facing the following problems?

When collaborating with local and overseas Dome array manufacturers in Denmark, purchasing and engineering teams often encounter the following core issues:

- Long prototyping cycles: Repeated modifications to initial Dome array prototypes, disconnect between design and production, leading to prolonged verification cycles.

- Inconsistent tactile feel: Significant differences in rebound force, travel distance, and lifespan of domes across different batches, affecting the end product experience.

- Insufficient design support capabilities: Manufacturers can only “produce according to drawings,” unable to provide engineering advice on dome selection, array structure, and positioning accuracy.

- Difficult transition from small-batch to mass production: Samples are qualified, but yield decreases, dimensional deviations, or assembly problems occur during mass production.

- Uncontrollable delivery times: Reliance on external suppliers for materials and dispersed production capacity lead to frequent delivery delays.

- Non-transparent cost structure: Low quotes but hidden costs for rework, re-prototyping, and delayed delivery, resulting in high overall project risk.

End-to-end process guarantee from requirements to delivery

As a professional Dome array manufacturer, EBest Circuit (Best Technology) provides Denmark customers with a one-stop solution from requirements confirmation to mass delivery:

- Preliminary engineering evaluation: Optimizing dome structure and parameters based on application scenarios (medical, industrial, consumer electronics)

- Precise prototyping: Quickly producing verifiable samples, ensuring structure, tactile feel, and lifespan are right the first time.

- Stable mass production system: Proprietary molds, stamping, bonding, and testing processes to avoid outsourcing risks.

- Controllable delivery: Standardized production plan + rapid logistics response to ensure project timelines.

- Continuous technical support: Engineers directly involved in both sample and mass production stages.

This is not simply “making domes,” but helping customers successfully integrate Dome arrays into their products and achieve stable market launch.

Why choose us? EBest Circuit (Best Technology)’s core advantages

Choosing EBest Circuit (Best Technology) means choosing a Dome array manufacturing partner that can truly support the long-term success of your project:

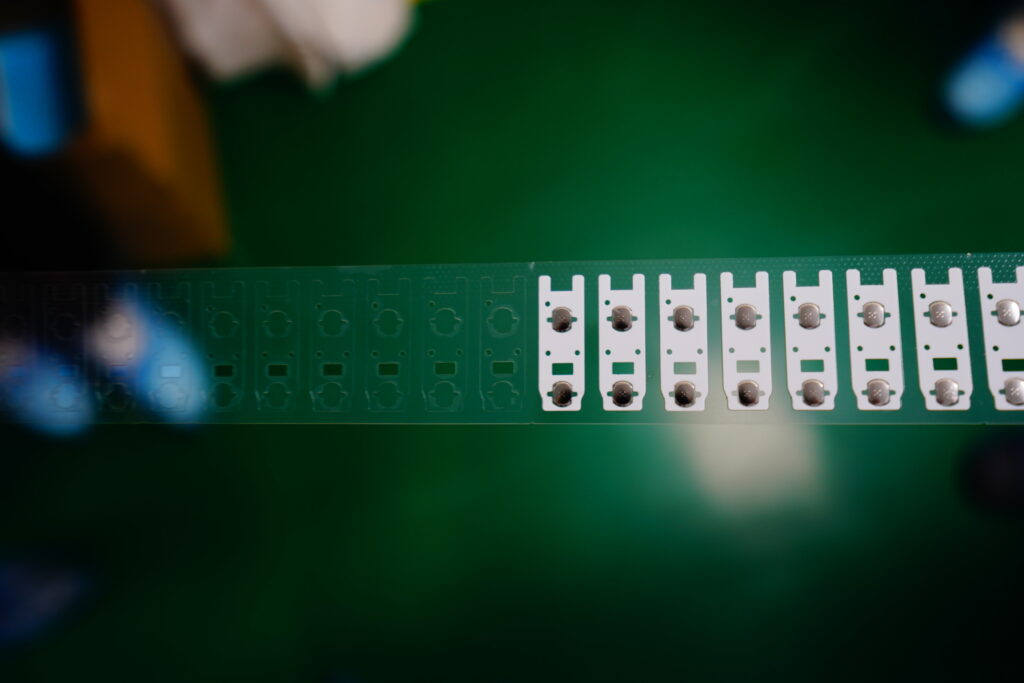

- ±0.05mm array positioning accuracy: Ensuring perfect alignment of domes with PCBs and conductive films, reducing assembly errors.

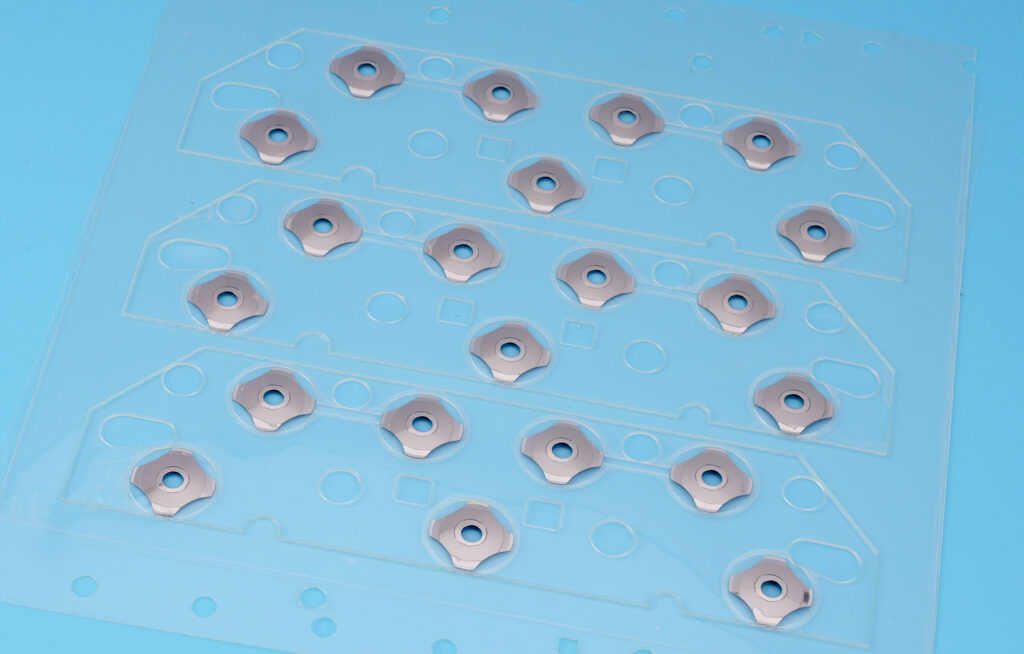

- Over 1 million press cycles lifespan: Meeting high-reliability application requirements through material and structural optimization.

- Fast prototyping capabilities: Free initial samples, complete technical parameter package, shortening project verification cycles.

- Adaptable to automated assembly: Supporting Tape & Reel packaging, significantly improving SMT assembly efficiency. Mature OEM/ODM experience: Deep understanding of different national markets and industry standards, reducing communication costs.

- Stable delivery and response mechanism: 48-hour technical feedback, standard delivery preparation completed within 7 days.

Top 10 dome array manufacturers in Denmark

| Company Name | Process Capability | Advantage |

|---|---|---|

| EBest Circuit (Best Technology) | Precision injection molding, SMT assembly, assembly and testing, custom design, rapid prototyping | 2-3 day fast delivery, ±0.01mm high-precision manufacturing, full-process quality control, no minimum order quantity (MOQ) restriction, 2-year warranty |

| Danish Dome Tech A/S | Standard specification Dome array manufacturing, simple assembly, routine inspection | Sufficient local production capacity, standard products available in stock, cost-effective pricing |

| Nordic Array Manufacturing ApS | Medium to high-precision manufacturing, small batch customization, prototyping service | Professional technical team, fast response, standardized cooperation process |

| DK Precision Dome Ltd | Precision assembly, quality inspection, customized process optimization | Comprehensive quality control system, low defect rate, timely after-sales response |

| Scandinavian Dome Solutions | Full-process manufacturing, design consultation, mass production | Large production scale, significant cost advantage for bulk orders, stable long-term cooperation |

| Elite Dome Denmark A/S | High-precision prototyping, customized manufacturing, special material processing | Wide range of material choices, strong technological innovation capability, high compatibility with high-end markets |

| Denmark Array Tech Co., Ltd | Conventional specification manufacturing, simple customization, fast shipping | Short delivery cycle, simple operation process, efficient customer service |

| Royal Dome Manufacturing ApS | Precision manufacturing, assembly and testing, full-process service | Good brand reputation, rich industry experience, strong service capability for major clients |

| Green Dome Denmark | Eco-friendly material manufacturing, conventional customization, batch production | Green environmental certification, complies with EU environmental standards, sustainable development concept |

| Fast Dome Solutions DK | Rapid prototyping, small batch manufacturing, emergency delivery | Strong emergency response capability, fast prototyping speed, high adaptability for urgent/replenishment orders |

How to Choose a Denmark Dome Array Manufacturer?

When choosing a Denmark dome array manufacturer, what truly determines the success or failure of a project is not the price, but whether the manufacturer possesses the systemic capabilities from design to mass production:

- Does the manufacturer have the capability to design the dome array structure and arrangement?

- Can they accurately control trigger force, rebound curve, and stroke consistency?

- Do they support rapid prototyping and guarantee that samples are representative of mass production?

- Do they have a compatible solution for automated assembly (SMT)?

- Do they have long-term stable mass production capabilities and a quality system?

- Can they provide engineering-level technical support, not just sales support?

- Are they familiar with the pace of international customer and multinational project delivery?

Why is EBest Circuit (Best Technology) the optimal choice?

Because we don’t just produce according to drawings; we get involved in engineering evaluation from the early stages of the project:

- We optimize dome specifications, array spacing, and positioning structures based on the customer’s PCB and application scenarios.

- We execute the prototyping phase using mass production processes to ensure reproducible verification results.

- We have established a flexible production scheduling mechanism to address the common needs of small batches and multiple models in the Denmark market.

This means that when customers choose EBest Circuit (Best Technology), they are actually reducing overall project risk, not just choosing a supplier.

Core Pain Points of Denmark Dome Array Manufacturers

From a professional manufacturing perspective, common core pain points in Denmark dome array projects include:

- Difficulty in maintaining array consistency over the long term

- Good sample performance, but decreased yield in mass production

- Misalignment between the dome and the PCB/conductive film

- Fluctuations in tactile parameters between batches

- Lack of design considerations for automated assembly

- Slow problem feedback and unclear responsibility boundaries

EBest Circuit (Best Technology)’s solution is “systematic control”:

- Through ±0.05mm array positioning accuracy, we ensure long-term stable alignment between the dome and contacts.

- We unify molds, materials, and stamping parameters to avoid batch differences.

- We consider SMT assembly and Tape & Reel directionality during the design phase.

- We establish a complete testing process for lifespan, rebound force, and consistency.

We don’t just solve individual problems; we prevent these problems from occurring in the first place.

How to analyze the manufacturing capabilities of a Denmark dome array manufacturer?

Evaluating the manufacturing capabilities of a Denmark dome array manufacturer requires focusing on the following key points:

- Dome stamping precision and stability

- Array bonding and positioning control capabilities

- Consistency in mass production

- Durability and tactile testing capabilities

- Compatibility with automated assembly

- Whether molds are owned in-house

- Completeness of quality control processes

- Coordination between engineering and production

EBest Circuit (Best Technology)’s advantage lies in “owning all key capabilities”:

- In-house stamping and array manufacturing system, avoiding quality control issues caused by outsourcing

- Mature dome array mass production experience, supporting long-term stable supply

- Coordination among engineering, production, and quality teams to ensure design intent is fully executed

This means that choosing EBest Circuit (Best Technology) allows customers to establish a sustainable supply chain node.

How to evaluate the delivery time of a Denmark dome array manufacturer?

Delivery time evaluation is not just about “how many days for delivery,” but whether deliveries can be made as promised every time:

- Whether they have a complete in-house production line

- Whether they rely on third-party processing

- Efficiency of switching between prototyping and mass production

- Material and mold preparation capabilities

- Production scheduling flexibility

- Project priority management capabilities

The core reason why EBest Circuit (Best Technology) can achieve fast delivery in 2-3 days is:

- Standardized dome array processes and a mature mold system

- Maintaining material and capacity reserves for commonly used specifications

- Project-based production scheduling management to avoid order disruption

- Technology and production proceed simultaneously, rather than through layered communication

Therefore, our “speed” is not achieved by compromising quality, but by leveraging efficiency advantages based on long-term manufacturing experience.

Denmark Dome Array Manufacturer FAQs

- Q1: Can the dome array be fully customized?

Yes, including dome specifications, array layout, mounting method, and packaging.

- Q2: Are small-batch projects supported?

Yes, we can quickly handle projects from prototyping to small-batch production.

- Q3: How do you ensure consistent tactile feel over the long term?

Through material control, mold consistency, and full-process inspection.

- Q4: Do you support automated SMT?

Yes, we provide Tape & Reel solutions.

- Q5: How are engineering issues communicated?

Engineers communicate directly, providing fast and clear responses.

If you are looking for one of the top 10 dome array manufacturers in Denmark, EBest Circuit (Best Technology) is an ideal long-term partner that combines precision, stability, delivery time, and engineering support.