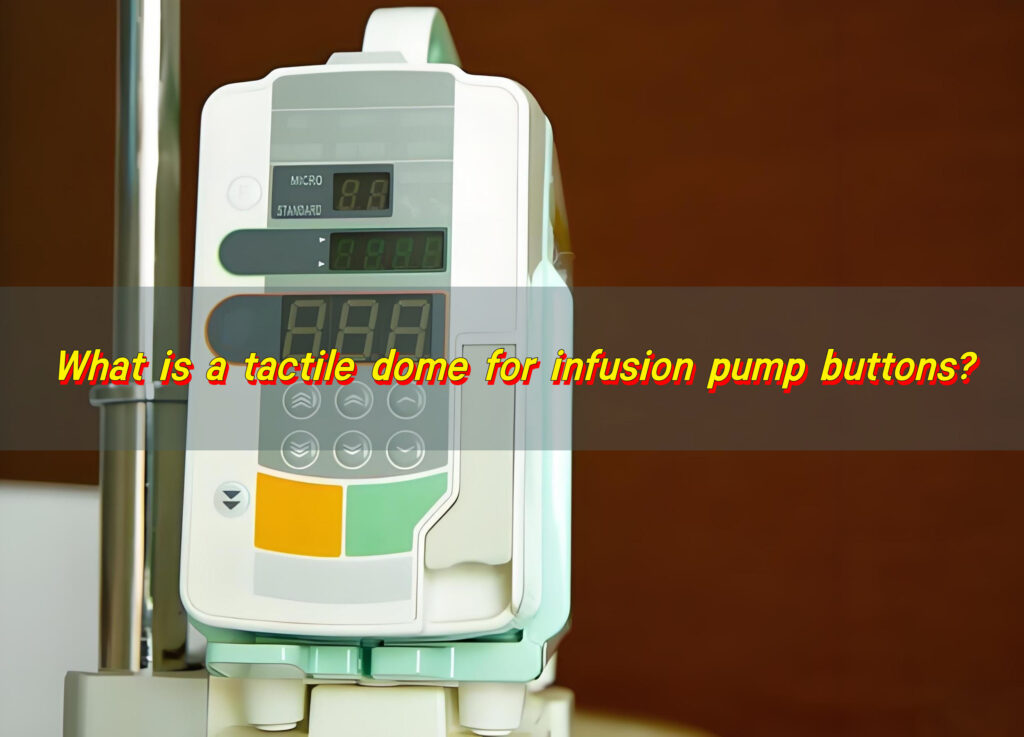

Tactile dome for infusion pump buttons is a small metal snap dome that provides clear tactile feedback when a button is pressed. The distinct “click” confirms that the input has been registered, helping medical staff operate the pump accurately and confidently.

In infusion pumps, tactile domes are built into membrane or metal dome array structures to ensure consistent force, fast response, and long service life.

What are tactile buttons?

Tactile buttons are buttons that give physical feedback when pressed. You feel a clear response. It may be a snap. It may be a click.

In daily life, tactile buttons are everywhere. Remote controls use them. Industrial panels rely on them. Medical devices depend on them the most. The reason is simple. Feedback reduces doubt.

When a nurse presses a button on an infusion pump, they cannot guess. They must know the command went through. A tactile button answers that need. The finger feels the action. The brain gains confidence.

Tactile buttons are not about sound. They are about feel. Some are silent. Some are soft. Some are firm.

In healthcare, gloves are common. Lighting may be low. Alarms may sound nearby. In such conditions, touch becomes critical. A tactile button cuts through noise and distraction.

That is why tactile buttons are standard in tactile medical pumps. They support fast operation. They reduce errors. They help users stay focused.

What is a tactile dome switch?

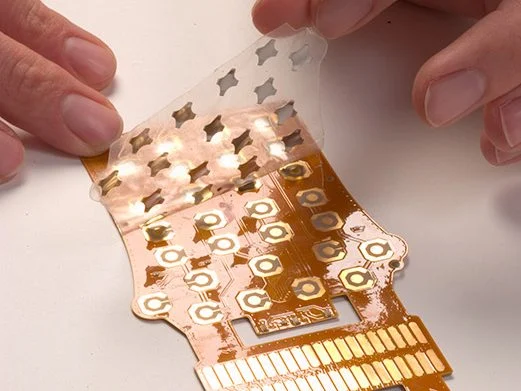

Tactile dome switch is the core part inside a tactile button. It is usually a small metal dome. Some people call it a snap dome. When pressed, it collapses and makes contact. When released, it returns to shape. This movement creates the tactile response. The snap feeling comes from the dome’s structure.

A tactile dome switch is thin. It saves space. It fits well into compact devices like infusion pumps. Despite its size, it is strong. It can handle repeated pressing without losing shape.

The dome sits between a printed circuit and a top layer. When pressed, it bridges contacts on the board. That completes the circuit. Different domes create different feels. A sharp snap feels crisp. A softer snap feels gentle.

Are membrane switches tactile?

Membrane switches can be tactile. They can also be non-tactile. The difference lies in the structure.

A basic membrane switch uses flat layers. When pressed, two layers touch. There is little feedback. The press feels smooth and quiet. This works for simple panels.

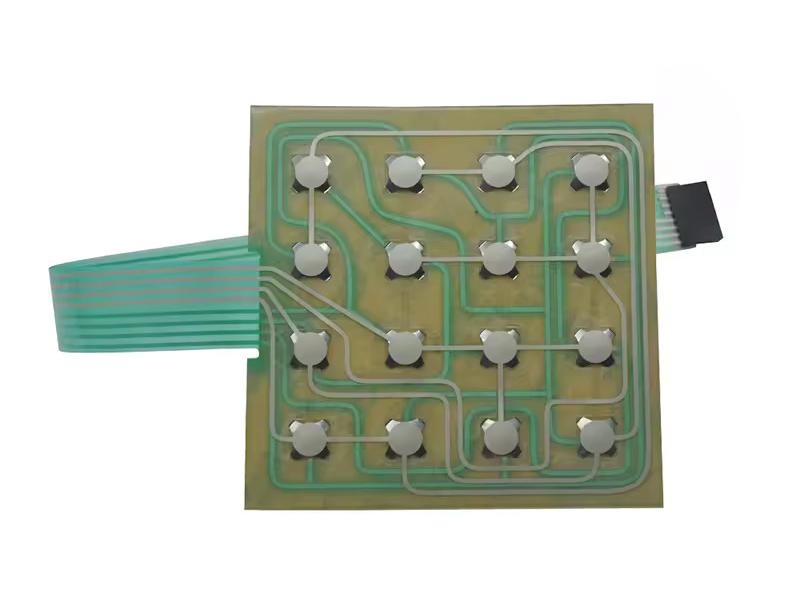

To add feedback, designers place a tactile dome under the membrane. The dome provides the snap. The membrane protects the surface. Together, they form a tactile system.

In infusion pumps, this combination is common. The membrane keeps the surface sealed. It resists liquid and dust. The tactile dome underneath gives clear feedback. This design supports hygiene. It also supports durability. There are no open gaps. Cleaning is easier. Reliability improves.

So yes, membrane switches can be tactile. When paired with a metal dome array, they meet medical standards well.

What is a tactile dome switch used in infusion pumps?

In infusion pumps, tactile dome switches control key functions. These include start, stop, rate setting, and menu navigation.

The tactile dome for infusion pump buttons ensures that every press counts. It prevents accidental input. It helps users feel each step.

Infusion pumps often run for long hours. Adjustments may happen at night. Lighting may be dim. In such moments, touch guides the user.

A tactile dome switch also supports speed. Nurses move quickly. They cannot pause to confirm every screen change. The snap confirms the action right away.

In short, tactile dome switches work reliably and consistently, ensuring accuracy at all times.

Why use a tactile dome switch in tactile medical pumps?

Medical pumps demand trust. Buttons are the main point of contact. Using a tactile dome switch adds confidence. The user knows the device responded. There is no need to double press. That reduces mistakes.

Tactile domes also support consistency. Each press feels the same. In emergencies, every second matters. A clear tactile response saves time.

From a design view, tactile domes are reliable. They handle high cycles. They resist wear. They suit long service life.

For tactile medical pumps, these qualities matter. Devices must perform day after day.

What are the benefits of tactile dome switches in medical pumps?

- The benefits start with feedback. Clear feedback improves accuracy. Users trust what they feel.

- Another benefit is durability. A quality tactile dome can last over one million presses.

- Space saving is another plus. Tactile domes are thin. Designers can keep pumps compact and lightweight.

- Hygiene also improves. Domes work well with sealed membranes. This supports cleaning and infection control.

- There is also design freedom. Different dome shapes offer different forces. From a production view, metal dome arrays support efficient assembly. They align well. They reduce placement errors.

All these benefits support safer pumps. They also support better user satisfaction.

How does a metal dome array work in infusion pumps?

Metal dome array groups multiple domes on a carrier layer. Each dome aligns with a circuit contact. This creates a grid of switches.

In an infusion pump, the array sits under the button panel. When a button is pressed, the matching dome collapses. The circuit closes. The command is sent.

Using an array improves consistency. Each dome sits in the right position. Spacing stays accurate.

Arrays also simplify assembly. Automated machines can place them quickly. This reduces human error.

For maintenance, arrays offer stability. Domes stay fixed. They do not shift over time.

In high-use devices, this matters. Stable input keeps performance steady. That protects both device and patient.

Which tactile dome is best for infusion pump buttons?

The best tactile dome depends on the pump design and user needs.

- Force level is key. Some pumps need a lighter touch. Others need firmer feedback. The choice must match the context.

- Shape also matters. Round domes offer even force. Triangle domes guide finger placement. Four-leg domes support clear contact.

- Material quality is critical. Medical devices need stable metal. Consistent performance matters more than cost.

- Compatibility with the membrane is also important. The dome must work smoothly with the top layer.

For infusion pumps, reliability leads the decision. A proven tactile dome switch supports safety and trust.

Conclusion:

Tactile domes play a quiet yet vital role in infusion pumps. They turn simple button presses into confident actions. They support accuracy, speed, and trust.

From tactile buttons to metal dome arrays, each part serves a purpose. Together, they create a reliable user interface for tactile medical pumps.

If you would like expert support or samples for your project, please contact our team. Email: sales@metal-domes.com