Choosing the right Top 10 dome array manufacturers in Sweden can significantly influence the performance, durability, and user experience of your electronic products. From industrial control panels to medical devices and consumer electronics, dome arrays play a crucial role in delivering consistent tactile feedback and long-term reliability.

Are you facing the following problems?

As a Dome Array manufacturer serving Nordic customers for many years, we deeply understand the pain points that local companies often encounter in design, prototyping, and mass production, including:

- High costs for small-batch trial production, yet still long lead times

- Manufacturers unable to provide professional engineering guidance when customizing Dome structures

- Poor consistency in button feel, with significant differences between batches

- Quality issues such as unstable Dome Array adhesion, delamination, and misalignment

- High-demand industrial products failing to achieve a lifespan of over one million cycles

- Slow supplier communication and untimely after-sales technical support

BEST Technology’s solution

End-to-end process guarantee from requirements to delivery

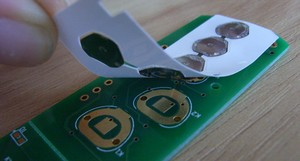

As a professional Dome Array manufacturer, we provide a complete process from engineering evaluation —> structural design —> material selection —> prototyping and verification —> mass production —> quality inspection —> packaging and delivery, ensuring that every step is controllable, transparent, and reliable for our customers.

Through strict ISO9001 processes, million-cycle lifespan testing, ±0.05mm precision control, and Tape & Reel high-speed mounting and packaging solutions, we provide a stable and reliable delivery experience for our customers’ mass manufacturing in Sweden.

Why choose us?

- 20 years of professional experience: Focusing on metal domes and Dome Array manufacturing, with industry cases covering industrial control, medical electronics, communication equipment, consumer electronics, and other fields.

- Strong engineering capabilities: Providing engineering support such as structural optimization, tactile feel simulation, and material selection to help customers reduce costs and minimize iteration cycles.

- Million-cycle stable lifespan: Our self-developed Dome structure has a lifespan of over 1,000,000 cycles, maintaining consistent click feel and rebound speed.

- ±0.05mm precision: High-standard bonding process and die-cutting technology ensure precise Dome positioning and higher stability.

- High-speed delivery advantage: Tape & Reel packaging + automated assembly shortens lead time to 7 days (industry average 15 days).

- International customer recognition: Exporting to over 40 countries in Europe and America, stably supplying multiple electronics companies in Sweden.

Top 10 dome array manufacturers in Sweden

| Company Name | Process Capabilities | Advantages |

|---|---|---|

| BEST Technology | Dome design, custom metal Dome, Dome Array lamination, Tape & Reel SMT packaging, million-cycle life testing | Fast delivery, high precision, stable pricing, strong engineering team, free samples provided |

| Intertech Electronics | Membrane switch & Dome Assembly | Suitable for small and medium batches, can assist with structural design |

| Bergstrom Innovations | Industrial button structures, bump sheet design | Rich experience in industrial control products |

| Nordic Switch Solutions | Button structural components, metal sheet assemblies | Stable delivery, custom sizes available |

| Swedtech Manufacturing | Assembly OEM, button component assembly | Strong comprehensive processing capability |

| KeyDome AB | Metal Dome, button die-cutting | Suitable for small and medium electronic factories |

| NorDesign Components | Small batch Dome component manufacturing | Flexible order acceptance, fast response |

| ScandiTouch Interface | Customized touch + button modules | Supports hybrid interface design |

| DomeForm Scandinavia | Dome bending, lamination processing | Stable Dome precision |

| Nordic Flextronics | Electronic modules, button component processing | Basic Dome structure assembly capability |

How to choose a Sweden DOME ARRAY manufacturer?

- Does the manufacturer have independent metal dome production capabilities?

- Can they provide engineering support (tactile feel, travel distance, structural optimization)?

- Has the dome lifespan been verified for millions of cycles?

- Is the bonding accuracy achievable at ±0.05mm?

- Can they provide Tape & Reel packaging to improve assembly efficiency?

- Do they provide thorough sample testing and reports?

- Do they have ISO9001 standard processes?

- Is the delivery time transparent and controllable?

- Can they handle customized projects?

- Can they provide stable supply for 1-5 years or more?

Core Pain Points of Sweden DOME ARRAY Manufacturers (BEST Technology’s Solutions)

- Difficulty controlling tactile consistency —> We use precision stamping and strict QC monitoring for stable tactile feel across batches.

- Risk of dome misalignment and delamination —> ±0.05mm bonding technology + automated process

- Lifespan less than one million cycles —> Self-developed dome structure achieves over one million cycles

- Long lead times for small batches —> 7-day delivery, free initial samples

- Lack of technical communication —> 48-hour engineering response mechanism

- High overall cost —> Supports Tape & Reel automated assembly, saving 37%+ in labor costs

- Large batch variations —> Complete batch tracking and fully automated testing system

BEST Technology, through its mature processes, automated production lines, and engineering team, comprehensively addresses the quality and delivery issues that Sweden customers care about most.

How to evaluate a Sweden DOME ARRAY manufacturer’s production capabilities?

- Do they have an independent dome stamping production line?

- Can they perform material tensile strength, lifespan, and tactile feel tests?

- Do they have control over die-cutting precision?

- Do they have automatic or semi-automatic bonding equipment?

- Is the Dome Array dimensional tolerance controllable within ±0.05mm?

- Can they handle complex shapes or high-density key layouts?

- Can they provide reliability test reports?

- Can they consistently deliver large quantities?

- Can they provide SMT-ready Tape & Reel packaging?

- Is the QC process complete and transparent?

BEST Technology possesses independent capabilities in dome production, die-cutting, bonding, testing, and SMT Tape & Reel packaging, fully meeting all the above evaluation criteria and making us a trustworthy partner for Sweden customers.

How to evaluate the delivery time of Sweden Dome Array manufacturers?

- Do they have their own production lines (no outsourcing risks)?

- Can they handle both small and large batches quickly?

- Is the sample delivery time ?7 days?

- Is mass production delivery stable within 7–15 days?

- Do they provide real-time production progress feedback?

- Do they accept urgent orders?

- Do they have automated production equipment to improve efficiency?

- Are there diversified logistics options (air freight/express/sea freight)?

- Do they have a safety stock mechanism?

- Do they have experience shipping to the European region?

BEST Technology relies on high-speed automated bonding, Tape & Reel packaging, and a mature supply chain system to achieve expedited 7-day delivery, enabling Swedish customers to achieve timely mass production in urgent projects.

Sweden Dome Array Manufacturer Frequently Asked Questions (FAQ)

- Q1: Why is the tactile feel of my product inconsistent?

A: This is mostly due to inconsistencies in Dome batch precision or bonding deviations. We ensure consistency through strict Dome stamping precision and ±0.05mm bonding process.

- Q2: What if the Dome Array easily delaminates?

A: The key lies in adhesive selection and bonding pressure control. We use industrial-grade adhesives and perform constant temperature bonding to ensure firmness and stability.

- Q3: Why doesn’t the lifespan reach one million cycles?

A: Lifespan is affected by materials, structure, and process. We use high-strength stainless steel and optimized structural design, which can easily reach over one million cycles.

- Q4: Can you make special shapes or high-density buttons?

A: Yes, we support complex structures and customized die-cutting solutions.

- Q5: Are samples free?

A: BEST Technology supports free initial samples and provides complete technical parameters.

- Q6: Why is the delivery time unstable?

A: This is often due to outsourcing or insufficient equipment. We use a fully integrated factory process, ensuring stable and controllable delivery times.

- Q7: Can you provide Tape & Reel packaging for SMT use?

A: Yes, we support standardized SMT packaging, significantly improving placement efficiency.

- Q8: Do you comply with environmental regulations?

A: We provide full ROHS/REACH certification, suitable for the European market.

This article comprehensively analyzes the top 10 dome array manufacturers in the Swedish market and helps engineers quickly understand how to choose the most suitable supplier. BEST Technology is also a trusted top 10 dome array manufacturer partner for Swedish electronics companies.