Metal dome manufacturers in Germany are known for precision, durability, and tight actuation-force control. Many offer custom dome arrays with tailored layouts, PET layers, and adhesive options for industrial, automotive, and medical devices.

Are you facing the following problems?

- Long prototyping cycles (over 7 days), unable to quickly respond to urgent project needs?

- Poor compatibility between metal dome design and PCB pads, resulting in an assembly pass rate below 95%?

- Unstable manufacturing processes, resulting in large fluctuations in product contact resistance and a lifespan of less than 500,000 cycles?

- Small-batch custom orders (<500pcs) rejected, making it difficult to meet product development or niche market needs?

- Unprofessional material selection, unable to adapt to special scenarios such as high temperature (>85?) and high humidity (>90% RH)?

- Delayed after-sales response, no effective solution received within 72 hours of a quality issue occurring?

Why Choose Us? (BEST Technology)

With 20+ years of experience in the German metal dome industry, BEST Technology ranks among the top 10 core enterprises in the German metal dome supply chain, serving over 500 German and European companies. It boasts leading technological expertise and a renowned industry reputation.

- Extremely fast prototyping capabilities: Samples are delivered within 48 hours of core parameter confirmation. The design team provides PCB pad adaptation optimization solutions, ensuring a stable assembly pass rate exceeding 99.5%.

- Using imported SUS301/SUS304 stainless steel, combined with precision stamping (tolerance ±0.01mm) and vacuum heat treatment processes, products achieve a lifespan of over 1 million cycles, with contact resistance ?50? and fluctuation ?10%.

- No minimum order quantity (MOQ=1): Supports customized production from 1-10,000pcs. From design to mass delivery, a dedicated account manager provides one-on-one follow-up, with real-time progress updates.

- Full system certification guarantee: Certified by ISO9001, RoHS, and IATF16949. Certified products meet the stringent requirements of high-end applications such as automotive electronics, industrial control, and medical equipment.

- Exceptional after-sales service includes 24-hour technical support, solutions for quality issues within 48 hours, and technical rectification; zero-risk cooperation.

List of German Metal Dome Manufacturers

| Company Name | Process Capabilities | Core Advantages |

|---|---|---|

| BEST Technology | Precision Stamping (±0.01mm), Vacuum Heat Treatment, Gold/Nickel Plating Surface Treatment, PCB Adaptation Design, Customized Prototyping (48h Rapid) | No MOQ Restriction, 1 Million Cycles Lifespan, Full-Scenario Certification, 24h After-Sales, European Local Storage |

| Schurter GmbH | Metal Precision Molding, Contact Optimization, Mass Stamping, Assembly Integration | Industrial-Grade Quality Benchmark, Strong Mass Delivery Capability (Daily Capacity 100k+), Full Coverage of EU Environmental Standards |

| TE Connectivity Germany | Precision Metal Stamping, Electroless Nickel/Gold Plating, Reliability Testing (Salt Spray/High and Low Temperature) | Globally Renowned Brand, Deep Cooperation in Automotive Electronics, High Supply Chain Stability |

| Phoenix Contact GmbH & Co. KG | Stamping Molding, PCB Integration Design, Industrial-Grade Contact Manufacturing | Strong Adaptability to Industrial Control Scenarios, Complete Technical Documentation, Stable Delivery Cycle (±1 Working Day) |

| Harting Technology Group | Precision Metal Processing, Harsh Environment Resistant Surface Treatment, Custom Molding | Resistant to High and Low Temperatures (-40?~125?), Anti-Vibration and Shock, Advantages in Industrial Connector Matching |

| Festo SE & Co. KG | Micro Metal Dome R&D, Precision Stamping, Miniaturized Assembly | Rich Experience in Medical Equipment/Sensor Adaptation, Product Size Can Be as Small as 2mm×2mm |

| Siemens AG (Component Division) | Metal Stamping, Heat Treatment, Full-Process Quality Control | High-End Manufacturing Standards, Full Coverage of Automotive/Industrial Electronics Scenarios, Complete Certification System (ISO/IATF/RoHS) |

| Pepperl+Fuchs GmbH | Explosion-Proof Metal Dome Manufacturing, Precision Molding, Reliability Verification | Adaptation to Explosion-Proof Scenarios (Ex II), High Quality Stability (Defect Rate <0.1%), Professional Technical Support |

| Leuze electronic GmbH + Co. KG | Metal Stamping, Surface Treatment, Small-Batch Customization | Advantages in Sensor Matching, Flexible Delivery, Small-Batch Order Friendly (MOQ=50) |

| Balluff GmbH | Precision Metal Contact Manufacturing, PCB Lamination Optimization, Industrial Automation Adaptation | 20 Years of Experience in Industrial Automation, Timely After-Sales Service (48h On-Site in Germany) |

How to Choose a German Metal Dome Manufacturer?

- Verify Core Certifications: Prioritize manufacturers certified by ISO9001 (basic quality), RoHS (environmental protection), and IATF16949 (automotive electronics);

- Assess Technical Compatibility: Confirm whether they offer PCB pad design optimization and 3D simulation assembly services to avoid compatibility issues;

- Examine Prototyping and Customization Capabilities: Focus on prototyping lead time (?72 hours is ideal) and whether they support small-batch customization (MOQ?100pcs);

- Verify Core Product Parameters: Require test reports for contact resistance (?50?), lifespan (?500,000 cycles), and dimensional tolerance (within ±0.02mm);

- Investigate Manufacturing Processes and Materials: Prioritize manufacturers using SUS301/SUS304 stainless steel and precision stamping + vacuum heat treatment processes;

- Assess Delivery Stability: Check the on-time delivery rate over the past 6 months (?98%). Ideally, have backup production lines and safety stock of raw materials;

- Assess after-sales service: Confirm response time (?24h), quality issue handling solutions (e.g., free returns and exchanges), and technical support capabilities;

- Refer to customer case studies: Prioritize manufacturers with experience working with high-end clients in the same industry (e.g., automotive electronics, industrial control);

- Confirm price transparency: Avoid hidden fees (e.g., custom development fees, logistics fees), and request detailed quotations and warranty agreements;

Core pain points for German metal dome manufacturers

- High investment costs in precision equipment; insufficient process precision in small and medium-sized manufacturers, leading to easily exceeding dimensional tolerances (>±0.02mm);

- Large fluctuations in raw material prices (stainless steel strip increases by 10%-20%/year), with some manufacturers using inferior materials to control costs, resulting in shortened product lifespan;

- Design teams lack PCB adaptation experience, resulting in poor product-pad fit and assembly pass rates below 90%;

- Low production efficiency and high costs for small-batch orders, with most manufacturers setting high… MOQ (?1000pcs), rejecting small orders;

- Improper heat treatment process control leads to rapid product fatigue, with actual service life only 50%-70% of the claimed value;

- Immature surface treatment technology results in easy peeling of nickel/gold plating, affecting conductivity and corrosion resistance;

- Unstable cross-border supply chain and long raw material import cycle (>30 days) cause order delivery delays;

- An incomplete quality inspection system lacks full-process traceability, resulting in a high defect rate (>0.5%);

- Weak technical support capabilities prevent providing value-added services such as design optimization and installation guidance;

- Slow after-sales response and long quality issue handling cycle (>7 days) lead to high costs for cross-border rights protection.

How to assess the production capacity of a German metal dome manufacturer?

- Verify production equipment configuration: Confirm whether core equipment such as high-precision stamping presses (accuracy ? ±0.01mm), vacuum heat treatment furnaces, and surface treatment production lines are available;

- Require a process capability report (CPK): A CPK ? 1.33 for core processes (stamping, heat treatment) is considered acceptable, and ? 1.67 is considered excellent;

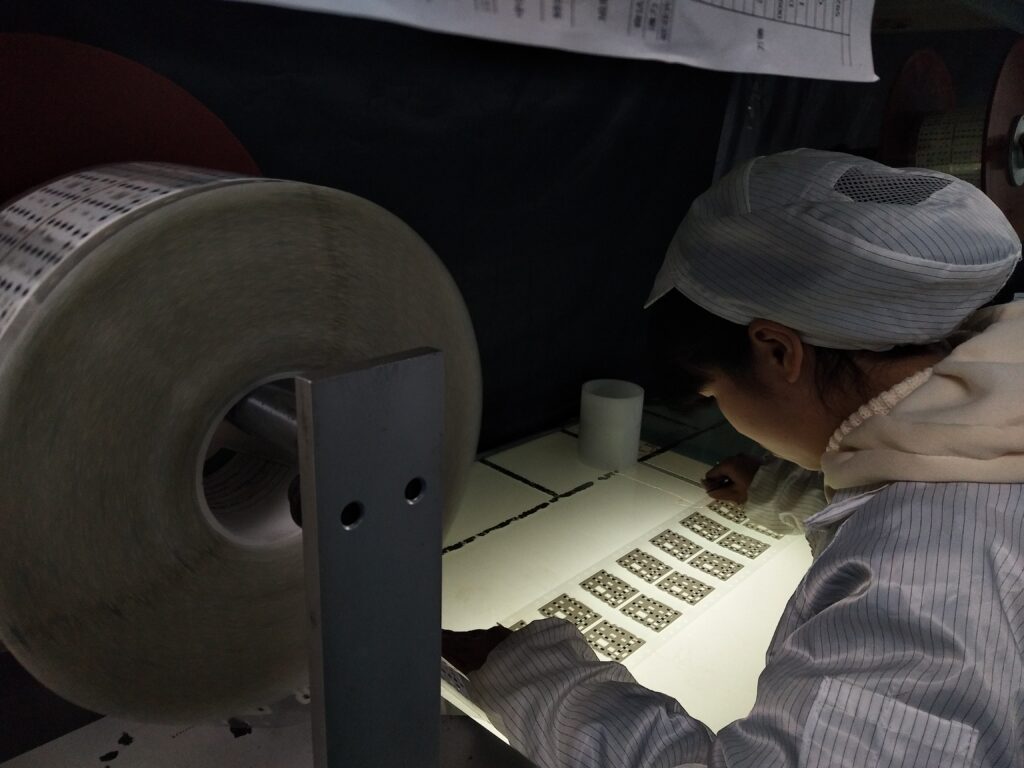

- Verify testing equipment and processes: Confirm whether professional equipment such as projectors, contact resistance testers, and lifespan testers are available, and whether full inspection (100% inspection) or sampling inspection (AQL 0.65) is performed;

- Assess R&D team strength: Confirm the percentage of R&D personnel (?10% is preferred), their ability to provide customized designs and process optimization solutions, and the R&D cycle (?15 days is preferred);

- Examine workshop management and capacity planning: Review the implementation of 5S management, and whether there is a clear production schedule and equipment maintenance plan;

- Conduct small-batch trial production verification: Achieve a yield of 100-500 pieces. Trial production: Testing product dimensional tolerances, contact resistance, assembly pass rate, and other indicators;

- Verification of certification and compliance capabilities: Confirming whether the product meets the environmental and safety standards of the target market (e.g., the EU) and whether it can provide testing reports;

- Assessing supply chain stability: Understanding the number of core raw material suppliers (?2), the configuration of alternative production lines, and the ability to cope with unforeseen risks.

How to assess the delivery time of a German metal dome manufacturer?

- Define clear standard delivery cycles: Require manufacturers to provide written commitments regarding sampling time (ideally ?72 hours) and bulk delivery time (ideally ?15 working days);

- Assess emergency order response capabilities: Confirm whether expedited services are supported, the expedited timeframe (e.g., sampling 24-48 hours), and the corresponding fees;

- Check raw material inventory: Confirm whether there is sufficient safety stock of core materials (stainless steel strip, plating materials) to avoid delays due to raw material shortages;

- Understand production scheduling transparency: Confirm whether a channel for tracking order production progress can be provided (e.g., online system, real-time synchronization with account managers);

- Assess logistics partnerships: Confirm whether there are long-term partnerships with international logistics providers such as DHL, UPS, and DB Schenker, and whether dedicated logistics lines can be provided;

- Check historical delivery data: Request on-time delivery rate and the percentage of delayed orders for the past 6 months, and analyze the reasons for delays (e.g., raw material or equipment failures);

- Assess backup capacity: Confirm whether there are backup production lines and whether rapid switching is possible in case of a single equipment failure to ensure delivery schedules;

- Clarify delay compensation policies: Stipulate liability for delayed delivery in the contract (e.g., 0.5% of the order amount per day). (Compensation), reducing cooperation risks;

- Negotiation of phased delivery solutions: For large-volume orders, confirm whether phased delivery is supported (e.g., 30% per month) to meet project phase requirements.

German Metal Dome Manufacturer Common Questions and Solutions (FAQ)

- Q: Frequent contact problems occur after metal dome installation. How to handle this?

A: ? First check the fit between the product and the PCB pads. If it’s a design compatibility issue, contact the manufacturer for a free PCB pad optimization solution; ? If it’s a product quality issue (e.g., excessive contact resistance), provide a test report, and the manufacturer will resend qualified products within 48 hours and bear the round-trip shipping costs; ? Subsequently, select manufacturers that support 3D simulation assembly confirmation to avoid compatibility issues in advance.

- Q: Most manufacturers refuse to accept small-batch custom orders (<500pcs). How to solve this?

A: ? Choose a manufacturer without MOQ restrictions (such as BEST Technology) and communicate customization needs and technical parameters in advance; ? Negotiate a small customization development fee with the manufacturer (usually 500-1000 Euros), which can be deducted after bulk orders; ? Consolidate multiple small orders and place a single order to increase order value and gain manufacturer support.

- Q: The product’s elasticity decreases after 6 months of use, and its lifespan does not reach the claimed 1 million cycles. How can I protect my rights?

A: ? Provide the manufacturer with proof such as usage scenarios and lifespan test data, based on the warranty agreement (usually 1-3 years); ? After verification, the manufacturer will replace the product with a qualified one free of charge and provide a product lifespan optimization plan (such as changing materials or adjusting heat treatment processes); ? Subsequently, choose manufacturers that provide third-party lifespan test reports (such as SGS, TÃœV) to ensure the authenticity of the parameters.

- Q: The delivery cycle for cross-border orders is as long as 45 days, far exceeding expectations. How can this be shortened?

A: ? Choose manufacturers with local warehousing in Germany to prepare inventory in advance, shortening the delivery cycle to 3-7 days; ? Negotiate with manufacturers to use dedicated logistics services (such as DHL Express) to shorten the cross-border delivery cycle to 15-20 days; ? Sign long-term cooperation agreements, agreeing on safety stock levels to ensure rapid response to urgent orders.

- Q: How to prevent the metal dome from detaching from the PCB after soldering?

A: ? Control soldering parameters: soldering temperature ?260?, soldering time <3 seconds to avoid high-temperature damage to the product; ? Choose products with nickel/gold plating (stronger adhesion), and request the manufacturer to provide a plating adhesion test report; ? The manufacturer provides soldering process guidance, recommends the type of flux used, and provides customized soldering positioning fixtures if necessary.

- Q: After customized design, the sample product does not match the required parameters (such as size, flexibility), how to handle this?

A: ? Sign a technical confirmation form with the manufacturer before prototyping, clearly defining core parameters (dimensions, elasticity, contact resistance) and acceptance standards; ? If the prototyping product does not meet the requirements, the manufacturer will reproduce it free of charge until the requirements are met, and optimize the design communication process (e.g., provide 3D model confirmation); ? Require the manufacturer to conduct small-batch assembly testing (?10pcs) during the prototyping stage to ensure product compatibility.

- Q: What if the product rusts in a high-temperature and high-humidity environment (e.g., an industrial workshop)?

A: ? Select a metal dome that meets IP65 protection standards, and require the manufacturer to use gold/nickel plating + passivation treatment; ? The manufacturer should provide a salt spray test report (?48 hours) to ensure the product’s corrosion resistance; ? Rusted products will be replaced free of charge according to the warranty policy, and the storage environment will be optimized afterwards (e.g., sealed packaging, placement of desiccant).

- Q: What if 10% of the products in a bulk order have dimensional tolerances exceeding the tolerance limit (?±0.02mm)?

A: ? Require the manufacturer to unconditionally return or replace non-conforming products and bear related losses; ? Require the manufacturer to optimize production processes (such as adjusting stamping dies), and add a full inspection step to subsequent orders to ensure dimensional tolerances ? ±0.01mm; ? Sign a quality agreement stipulating a maximum defect rate (e.g., ?0.1%), with proportional compensation for exceeding the limit.

- Q: Products need to comply with automotive electronics IATF16949 certification, but some manufacturers do not possess it. How to resolve this?

A: ? Prioritize manufacturers that have passed IATF16949 certification and request certification certificates and automotive electronics customer cooperation cases; ? If the manufacturer has not yet obtained certification, negotiate with a third-party authoritative organization (such as TÃœV Rheinland) to issue a product compliance test report; ? Require the manufacturer to provide product traceability documents (such as batch management records and raw material certificates of conformity) to meet the requirements of the automotive electronics industry.

- Q: Encountering installation technical problems, and the manufacturer’s after-sales response is slow (>48 hours). How to resolve this efficiently?

A: ? Choose a manufacturer that provides 24-hour technical support and sign a service agreement to specify the response time; ? Request the manufacturer to provide detailed installation manuals, video tutorials, and other materials to avoid common problems in advance.