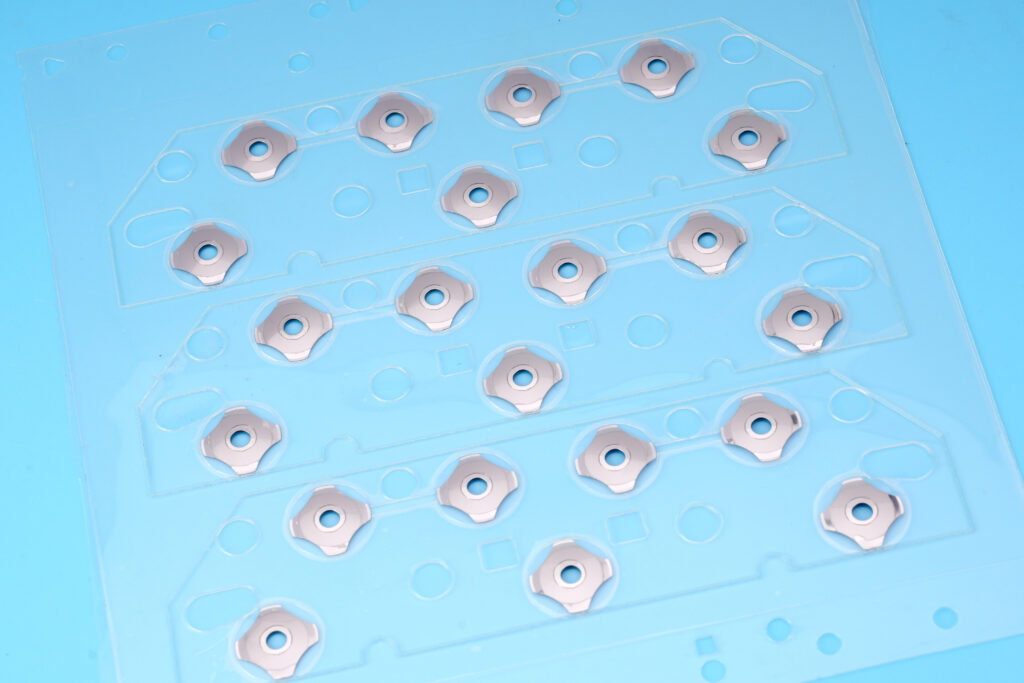

South Korean dome array manufacturer stand out for offering no-MOQ production, making them ideal for rapid prototyping and small-batch builds. With precise actuation, stable quality, and quick turnaround, BEST Technology provide flexible, reliable dome array solutions for electronics brands of all sizes.

Are you facing any of the following problems? (Dome array core pain points)

- Long prototyping cycles (average 7-15 days), unable to meet the needs of rapid project iteration, missing market windows;

- Insufficient support for customized design, making it difficult to accurately implement complex structures (such as miniaturization, high thermal conductivity requirements);

- Low manufacturing yield (especially for products with precision dimensional tolerances within ±0.01mm), resulting in high production costs;

- Inconsistency deviations during mass production, affecting the assembly accuracy and lifespan of end products;

- Limited material selection, with unstable supply of high-end environmentally friendly and high-wear-resistant materials, unable to meet industry certification standards;

- High technical communication barriers, manufacturers lack a thorough understanding of the needs of special application scenarios (such as automotive, medical devices).

Why choose us? (BEST Technology Core Advantages)

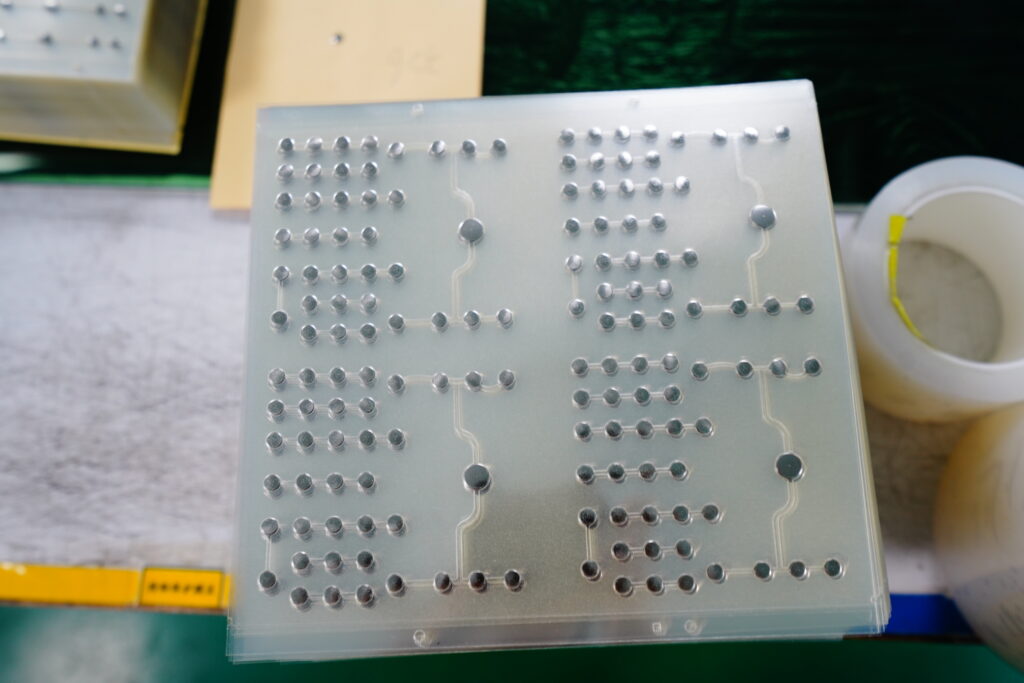

- Technological Leadership: With over 20 years of experience in the South Korean top 10 dome array industry, BEST Technology possesses core technologies in precision stamping and laser cutting, maintaining a yield rate consistently above 99.5% and meeting ultra-high precision requirements of ±0.005mm.

- Full-Process Customization Service: From prototyping (delivery within 24 hours) to mass production, BEST Technology provides integrated solutions for design optimization, material selection, and mold development, adaptable to both small-batch trial production and large-scale mass production.

- Top-Tier Supply Chain Resources: Direct partnerships with core material suppliers for South Korean top 10 dome arrays ensure a stable supply of special materials such as those with high thermal conductivity and resistance to high and low temperatures. BEST Technology also boasts comprehensive environmental certifications (RoHS, REACH).

- Capacity Guarantee: BEST Technology operates 3 automated production lines with a monthly capacity of 5 million sets, capable of handling urgent orders. On-time delivery rate has remained above 98% for five consecutive years.

- Industry Reputation: BEST Technology has served leading South Korean companies such as Samsung and LG, completing over 2000 projects. Customized projects;

- Dedicated after-sales support: Equipped with a 24/7 technical team, providing real-time order tracking throughout the entire lifecycle, offering solutions to quality issues within 48 hours, and lifetime technical upgrade consultation.

South Korean Dome Array Manufacturer List

| Company Name | Process Capabilities | Core Advantages |

|---|---|---|

| BEST Technology | Precision Stamping (±0.01mm), Vacuum Heat Treatment, Gold/Nickel Plating Surface Treatment, PCB Adaptation Design, Customized Prototyping (48h Rapid) | No MOQ Restriction, 1 Million Cycles Lifespan, Full-Scenario Certification, 24h After-Sales, European Local Storage |

| Schurter GmbH | Metal Precision Molding, Contact Optimization, Mass Stamping, Assembly Integration | Industrial-Grade Quality Benchmark, Strong Mass Delivery Capability (Daily Capacity 100k+), Full Coverage of EU Environmental Standards |

| TE Connectivity Germany | Precision Metal Stamping, Electroless Nickel/Gold Plating, Reliability Testing (Salt Spray/High and Low Temperature) | Globally Renowned Brand, Deep Cooperation in Automotive Electronics, High Supply Chain Stability |

| Phoenix Contact GmbH & Co. KG | Stamping Molding, PCB Integration Design, Industrial-Grade Contact Manufacturing | Strong Adaptability to Industrial Control Scenarios, Complete Technical Documentation, Stable Delivery Cycle (±1 Working Day) |

| Harting Technology Group | Precision Metal Processing, Harsh Environment Resistant Surface Treatment, Custom Molding | Resistant to High and Low Temperatures (-40?~125?), Anti-Vibration and Shock, Advantages in Industrial Connector Matching |

| Festo SE & Co. KG | Micro Metal Dome R&D, Precision Stamping, Miniaturized Assembly | Rich Experience in Medical Equipment/Sensor Adaptation, Product Size Can Be as Small as 2mm×2mm |

| Siemens AG (Component Division) | Metal Stamping, Heat Treatment, Full-Process Quality Control | High-End Manufacturing Standards, Full Coverage of Automotive/Industrial Electronics Scenarios, Complete Certification System (ISO/IATF/RoHS) |

| Pepperl+Fuchs GmbH | Explosion-Proof Metal Dome Manufacturing, Precision Molding, Reliability Verification | Adaptation to Explosion-Proof Scenarios (Ex II), High Quality Stability (Defect Rate <0.1%), Professional Technical Support |

| Leuze electronic GmbH + Co. KG | Metal Stamping, Surface Treatment, Small-Batch Customization | Advantages in Sensor Matching, Flexible Delivery, Small-Batch Order Friendly (MOQ=50) |

| Balluff GmbH | Precision Metal Contact Manufacturing, PCB Lamination Optimization, Industrial Automation Adaptation | 20 Years of Experience in Industrial Automation, Timely After-Sales Service (48h On-Site in Germany) |

How to Choose a South Korean Dome Array Manufacturer?

- Matching of Manufacturing Capabilities with Product Requirements (e.g., compatibility with precision tolerances, material types, and structural complexity);

- Core Certifications (Does the manufacturer possess industry certifications such as ISO9001, RoHS, REACH, automotive IATF16949, and medical ISO13485);

- Historical Yield and Quality Control Data (Provide yield reports for the past 6 months and third-party testing reports);

- Production Capacity and Order Suitability (Small-batch prototyping capabilities, peak mass production capacity, and response speed for urgent orders);

- Customized Design Support Capabilities (Does the manufacturer offer free design optimization and case studies of solutions for complex scenarios);

- Material Supply Chain Stability (Does the manufacturer source core materials in-house? Is there a backup supplier system?);

- On-time Delivery Rate and After-Sales Response Speed ??(Historical delivery data, after-sales problem resolution time, and technical support timeliness);

- Industry Reputation and Cooperation Cases (Has the manufacturer served the top 10 South Korean manufacturers?) (Compatibility between enterprise and end-user application areas);

- Cost control capabilities (pricing transparency, bulk purchase discount policies, no hidden costs);

- Technological iteration and R&D investment (keeping up with new industry technologies, R&D team size, number of patents).

Key Pain Points for South Korean Dome Array Manufacturers:

- 1. Reliance on imported high-end precision materials (such as high-elasticity stainless steel and thermally conductive silicone), resulting in long supply cycles and volatile prices.

- 2. Miniaturized and thin-film products (thickness <0.1mm) face high manufacturing difficulty, limiting yield improvement (some companies have yields below 90%).

- 3. High production costs for small-batch customized orders (<1000 sets), low production line switchover efficiency, and a lack of economies of scale.

- 4. Technological iteration lags behind end-user demand, resulting in insufficient adaptation to the special requirements of high-end fields such as automotive and medical applications (e.g., shock resistance and sterility).

- 5. Long mold development cycles (average 3-4 weeks), failing to meet customers’ needs for rapid prototyping and product iteration.

- 6. Inadequate quality control systems, leading to product consistency deviations during mass production (dimensional tolerance fluctuations exceeding ±0.02mm).

- 7. Weak supply chain coordination capabilities, resulting in an inadequate emergency response mechanism when upstream materials are scarce or downstream orders fluctuate.

- 8. High international logistics and tariff costs, and uncontrollable delivery cycles for export orders, impacting customer willingness to cooperate.

How to assess the production capacity of South Korean dome array manufacturers?

Advanced Production Equipment (Is it equipped with imported precision stamping machines, laser cutting machines, and automated testing equipment Equipment service life < 5 years);

Core Process Yield Data (Precision product yield ? 98%, regular product yield ? 99%, providing batch test reports for the past 3 months);

Production Capacity and Utilization Rate (Monthly production capacity ? 1 million sets, capacity utilization rate ? 70%, order range covering 1-10 million sets);

Quality Control System (Is it certified to ISO9001/IATF16949 Does it have SPC statistical process control Full inspection/sampling inspection ratio);

R&D Investment and Technology Reserves (R&D team accounts for ? 15%, annual R&D investment ? 5% of revenue, possessing ? 10 Dome array-related patents);

Material Supply Chain Stability (Number of core material suppliers ? 3, strategic partners account for ? 50%, material inventory turnover days < 30 days);

Customized Production Capability (Does it support complex structural designs, special material replacements, mold development cycle ? 2 months); Weekly testing capabilities (whether equipped with high and low temperature, abrasion resistance, and shock resistance testing equipment, and able to provide product reliability reports);

Production site management (whether 5S management, visualized production scheduling, and real-time order progress tracking system are implemented);

Employee professional competence (?90% of skilled workers hold valid certificates, receive regular skills training, and have a quality awareness assessment pass rate of ?95%).

How to assess the delivery time of South Korean dome array manufacturers?

- On-time delivery rate (on-time delivery rate ?95% in the past 6 months, with no major delays (>7 days));

- Order processing efficiency (order confirmation time ?24 hours, design confirmation cycle ?3 days, sample delivery cycle ?7 days);

- Production scheduling flexibility (whether it supports expedited production for urgent orders, priority production for small batch orders, and order change response speed ?48 hours);

- Supply chain collaboration capability (signing priority supply/transportation agreements with material suppliers and logistics providers, with core material preparation cycle ?7 days);

- Emergency response mechanism (whether it has developed contingency plans for material shortages, equipment failures, natural disasters, etc., and clearly defined compensation plans for delayed delivery);

- Inventory management capability (safety stock of core components ?15 days, finished goods inventory turnover days <15 days, avoiding inventory backlog or shortages);

- Logistics and distribution solutions (whether it provides multiple logistics channel options, international order customs clearance assistance, and cargo protection measures during transportation);

- Order progress visualization (whether it provides an online order tracking system and regularly synchronizes production progress (at least once a week)). (Times), advance notice before delivery);

- Bulk delivery capability (delivery cycle ? 30 days for large-scale orders (>1 million sets), flexible batch delivery options);

- Customer feedback and improvement (whether customer satisfaction with delivery time is collected, and continuous optimization of production scheduling and supply chain collaboration processes).

South Korean Dome Array Manufacturer Frequently Asked Questions (FAQ)

- Q: What is the delivery cycle for small-batch sampling (100-500 sets)? Can it be expedited?

A: The standard sampling cycle is 3-5 days. Expedited orders can be delivered within 24 hours. Product dimensions, materials, and structural requirements need to be clearly defined in advance. We will prioritize the allocation of mold and production line resources and simultaneously initiate material procurement and production preparation.

- Q: Can you meet the high shock resistance (?10G) and high temperature resistance (-40?~125?) requirements for automotive dome arrays?

A: We can provide customized automotive-grade solutions, using high-elasticity stainless steel and high/low temperature resistant silicone materials. Our products have passed multiple rounds of shock resistance and high/low temperature cycling tests (test reports are provided with the goods). We are IATF16949 certified and meet automotive industry standards.

- Q: The product dimensional tolerance requirement is ±0.005mm. Can this be consistently achieved? How do you ensure batch consistency?

A: We are equipped with imported precision stamping machines (accuracy ±0.001mm) and automated testing equipment (100% full inspection). Our core processes utilize SPC statistical process control. We provide 3 batches of samples for confirmation before mass production, and conduct sampling inspections every 2 hours during production to ensure dimensional fluctuations are ?±0.003mm.

- Q: Do the materials meet environmental standards? Can you provide relevant certification documents?

A: All materials are RoHS and REACH certified. Some products meet California Proposition 65 standards. We can provide material testing reports (MSDS, ICP) before cooperation. Bulk orders include copies of environmental certifications, and third-party re-inspections are supported.

- Q: What happens if design modifications are needed during order production?

A: Design modifications are available free of charge up to 3 days before production. After 3 days, mold adjustment costs and timelines need to be assessed (generally 1-2 days). A dedicated technical liaison is provided for real-time communication regarding modification details, ensuring adjustments do not affect core delivery milestones.

- Q: How are after-sales services handled for quality issues with bulk orders?

A: We respond within 24 hours of receiving feedback and provide a solution within 48 hours. For quality issues not caused by the customer, we offer free replacement of qualified products or a full refund. We have established a quality traceability system, allowing tracking of production equipment, material batches, and testing data for each batch of products.

- Q: Can you provide design optimization suggestions to reduce production costs?

A: We provide a free design optimization report within 3 days of order acceptance, reducing costs from three dimensions: material selection, structural simplification, and process adaptation (average cost reduction of 10%-15%). Drawing on our experience as a top 10 dome array manufacturer in South Korea, we optimize mold structure and production processes without affecting product performance.

- Q: How are logistics and customs clearance for international orders guaranteed?

A: We have long-term cooperation agreements with DHL and FedEx, ensuring a delivery cycle of 3-7 days for international orders; we provide complete commercial invoices, packing lists, and certification documents to assist customers with customs clearance; and we offer a variety of trade terms such as FOB and CIF to mitigate cost risks in response to tariff fluctuations.