What Are Peel and Place Metal Dome Arrays?

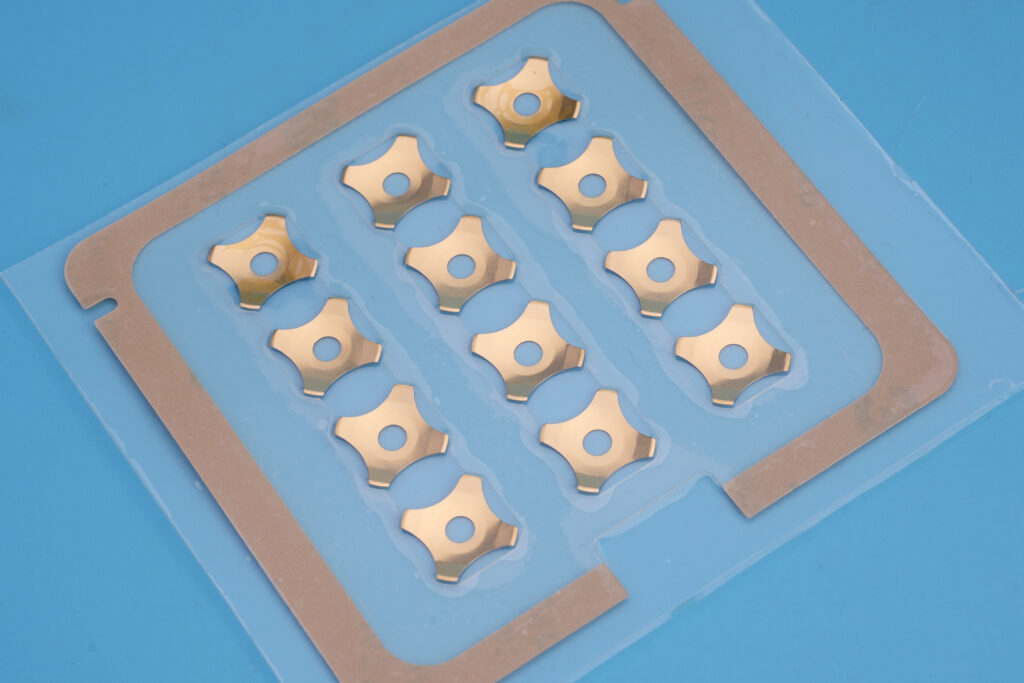

A peel and place metal dome array is a pre-positioned sheet containing multiple metal snap domes fixed on an adhesive carrier. The array is designed for easy application onto circuit boards or membrane switch layers. Each dome is seated in precise alignment, ready for placement on a printed circuit board (PCB), flexible circuit, or other tactile interface surfaces.

The “peel and place” concept means that the entire array can be peeled from its liner and applied directly onto the circuit in a single motion. It saves time, reduces manual alignment errors, and ensures consistency in large-scale assembly.

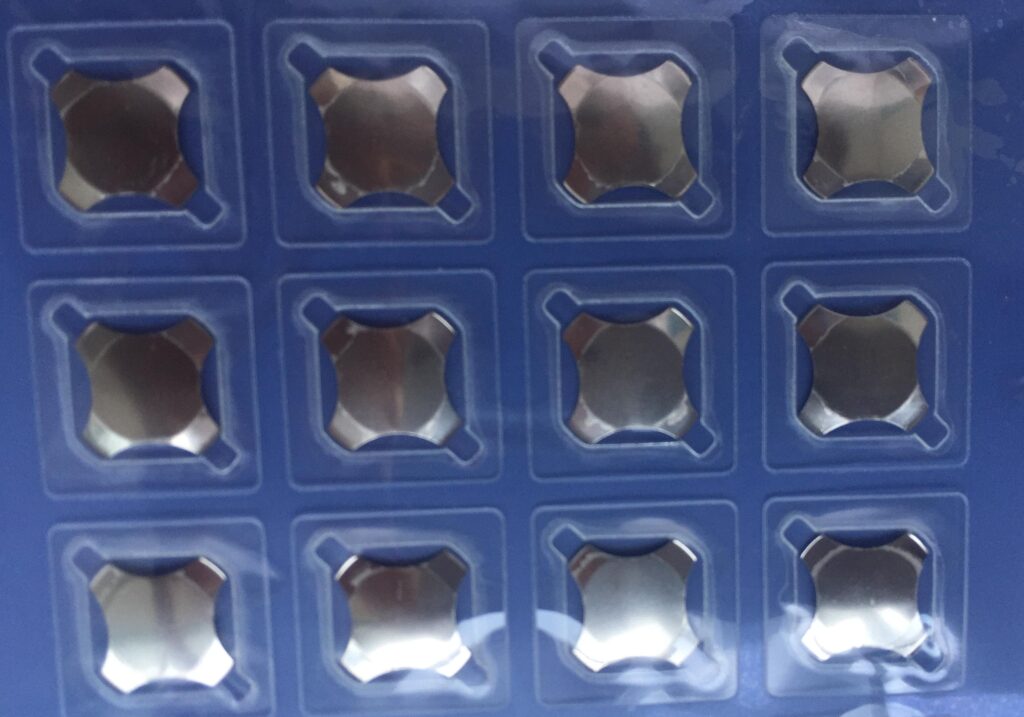

Each metal snap dome acts as a momentary contact switch. When pressed, the dome collapses, connecting the circuit underneath, and instantly returns to its original shape after release.

Peel and place arrays are often produced in customized layouts, depending on the product’s button structure. They can be made as full multi-key sheets or as single key dome arrays, also known as one key dome arrays, for smaller products or repair purposes.

Why Choose Peel and Place Metal Dome Array for PCB Design?

In PCB design, precision and speed matter. Each dome’s position is controlled within tight tolerances — usually within ±0.05mm.

Peel and place metal dome arrays simplify the entire assembly process. Instead of placing each dome by hand, the entire sheet can be aligned and applied in one step. This saves time and ensures every dome is placed correctly over its contact pads.

The adhesive film holding the domes in position keeps them secure during transport and assembly. It also prevents contamination or misalignment, ensuring a longer lifespan for the finished product.

For high-volume PCB assembly, peel and place arrays are a natural choice. They integrate smoothly into automated production lines and minimize rework caused by human errors.

How Is a Metal Snap Dome Applied to Circuits?

Applying a metal snap dome to a circuit can be done manually or by automation, depending on production scale. In a peel and place array, each dome is pre-located on an adhesive sheet.

The process begins with preparing the PCB or membrane switch layer. The contact pads are cleaned to ensure a dust-free surface. Next, the protective liner from the dome array is removed, exposing the adhesive side. The array is then carefully aligned over the circuit using registration marks or positioning holes.

Once aligned, gentle pressure is applied to fix the domes in place. For high-volume production, automated peel and place machines handle this task, placing thousands of domes per hour with unmatched precision.

The final step involves covering the domes with a top overlay or spacer layer, protecting them from moisture, dust, and physical wear. This layered structure completes the tactile switch assembly, resulting in a durable and responsive interface.

What Makes Metal Dome Keyboard Performance Better?

A metal dome keyboard (also known as a metal dome keypad) is not a traditional typing keyboard. It’s a tactile interface built for precision control, often used in industrial, automotive, and medical devices.

Its superior performance comes from the structure and materials of the metal dome array itself. Each dome, made from stainless steel or phosphor bronze, is formed to exact force and click specifications. When pressed, it provides a distinct tactile snap, which gives the user immediate feedback.

Users can feel each actuation, reducing errors in operation. The domes also recover instantly after release, maintaining consistent performance even after millions of presses.

Metal dome keyboards also support flexible design. The domes can be customized for different actuation forces, heights, and shapes, depending on product requirements.

The structure also protects the circuit from contamination. The overlay and spacer layers seal the domes inside, preventing dust or moisture from interfering with contacts.

Where Are Dome Switches Commonly Used?

Dome switches are found in many products around us. Their versatility makes them ideal for any device that needs a reliable tactile response.

- In consumer electronics, dome switches appear in remote controls, handheld devices, and portable instruments.

- In industrial environments, metal dome keyboards and snap dome switches are used in control panels, diagnostic devices, and communication systems.

- Medical equipment is another key field. The precision and cleanliness of dome arrays make them suitable for use in medical monitoring devices and surgical interfaces.

- Automotive controls, navigation systems, and security panels also rely on metal dome arrays.

- From compact handheld units to large equipment panels, dome switches ensure every touch is accurate and responsive.

What Are the Advantages of Peel & Place Dome Assembly?

The peel & place dome assembly process offers multiple advantages that benefit both manufacturers and end users.

- First, it improves accuracy. Each dome is placed in its correct position through pre-aligned arrays.

- Second, it speeds up production. Instead of picking and placing each dome manually, a single array can be applied in seconds. Automated machines can achieve placement speeds up to 100,000 domes per hour.

- Third, it saves costs. Labor time is reduced, waste is minimized, and the risk of misplacement or contamination is nearly eliminated.

- Fourth, it enhances durability. Domes in peel and place arrays are less likely to be damaged during assembly.

- Fifth, it improves product reliability. Because each dome is applied under clean, controlled conditions, the final tactile performance remains stable throughout its lifespan.

- Finally, it offers design flexibility. Arrays can be customized for any layout, from a single key dome array to a full multi-key sheet.

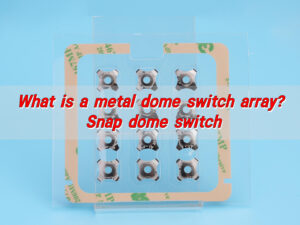

Who Should Use Single Key or One Key Dome Array?

Not every project requires a full dome sheet. In some cases, a single key dome array or one key dome array is a better fit.

These are small pre-cut sections of peel and place metal dome arrays containing only one dome. They are ideal for prototypes, repair work, or devices with few control buttons.

Single-key arrays are often chosen for frequent testing or small-batch assembly because they save time and avoid dealing with loose domes. The adhesive backing ensures the dome stays in place during application, offering the same precision as full arrays.

In repair scenarios, they allow easy replacement of a damaged dome without replacing the whole sheet. For custom or specialized electronics, single key dome arrays also make layout modification easier.

How Is Metal Dome Packing Done Efficiently?

Efficient metal dome packing is essential for maintaining product quality during storage and shipping. Domes are sensitive to dust, moisture, and static electricity, so controlled packaging methods are used.

The most common method for high-speed automation is Tape & Reel packaging. In this method, each dome is seated in a pocket on a continuous tape and wound onto a reel. The domes can then be automatically picked and placed by SMT equipment, ensuring consistency and reducing human contact.

For peel and place metal dome arrays, the arrays are usually packed with anti-static liners and vacuum-sealed pouches. This prevents oxidation and contamination. Each batch is labeled with part numbers, force values, and traceability codes for quality tracking.

Proper packing ensures that domes arrive at the assembly line in perfect condition. It also simplifies handling, reducing the need for manual inspection or cleaning before use.

Best Technology Co., Ltd. provides professional metal dome arrays, peel & place domes, and metal dome packing solutions with over 18 years of experience in the field.

If you’re looking for reliable peel and place metal dome arrays or customized tactile switch solutions, contact us today at sales@metal-domes.com