An EMI shielding metal dome is a tactile switch component designed to block electromagnetic interference (EMI) while maintaining precise electrical performance. Made from conductive stainless steel, it serves a dual purpose — providing tactile feedback for user interfaces and acting as a miniature EMI shield to protect circuits from unwanted noise and signal disruption.

What Is an EMI Shielding Metal Dome Used For?

An EMI shielding metal dome serves as a critical component for protecting electronic circuits from electromagnetic interference. It works as both a tactile element and a shielding structure. Inside a device, the metal dome sits under a keypad or switch, acting as a small conductive contact. When pressed, it completes the circuit, and its conductive material provides a path that can absorb or redirect unwanted electromagnetic signals.

In compact electronic systems, these domes create dual value. They provide tactile feedback for users and at the same time minimize EMI coupling between layers of circuitry. Devices such as medical equipment, automotive dashboards, and handheld controllers rely on them to maintain precision. Their thin, durable design helps preserve signal clarity without adding much weight or volume.

By preventing the escape or entry of interference, EMI shielding metal domes help maintain clean signals. This means fewer distortions, better accuracy, and longer product life.

How Does a Metal Dome Array Improve EMI Shielding?

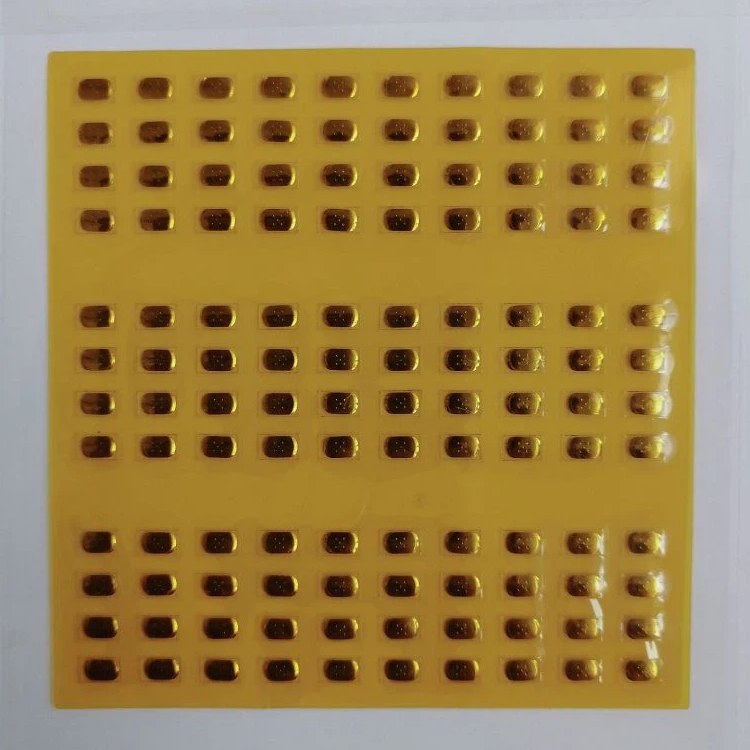

A metal dome array goes beyond individual dome protection. It combines multiple domes in one layout, often attached to a flexible adhesive sheet or polyester film. This structured design helps distribute EMI shielding more evenly across the entire keypad area.

Each dome in the array acts as a micro-shield, forming a continuous network of conductive paths. Together, they reduce cross-talk between traces and create a grounded barrier that reflects or absorbs interference. Because the array has uniform spacing and consistent metal layers, it maintains stable grounding throughout the device.

Another advantage lies in its simplicity. The metal dome array can be customized for different shapes, key forces, and circuit configurations. Whether for a rugged industrial controller or a sleek consumer gadget, its shielding performance remains strong.

In addition, dome arrays minimize assembly time. Since they come pre-aligned, manufacturers can integrate them directly into the control panel without manual placement of each dome.

What Makes Custom Metal Dome Array EMI Designs More Effective?

Custom metal dome arrays allow every feature, from dome geometry to material thickness, to be tailored to optimize shielding effectiveness.

When a device operates at specific frequencies, standard shielding may not fit the required bandwidth. Custom dome arrays can be tuned to block or absorb those exact frequencies.

The shape also matters. Flat, four-leg, or cross-type domes provide different pressure responses and surface contacts. A custom pattern ensures every dome sits precisely where EMI sources are strongest, providing targeted protection.

Thermal and mechanical stability is another reason to choose a custom design. In environments with high vibration or temperature changes, a tailored dome maintains its resilience and shielding consistency.

When the mechanical and electrical design align, the final product offers better tactile feel, longer lifespan, and stronger immunity against interference.

How Do Snap Dome Switches Reduce EMI Interference?

Snap domes, also known as tactile domes or metal snap domes, play an important role in EMI reduction. Their name comes from the sharp, tactile “snap” sensation felt when pressed.

When a snap dome is pressed, it forms a temporary electrical bridge. Its metal surface, being conductive, also forms a partial shield around the contact area.

Furthermore, when placed under a conductive overlay or grounded layer, snap domes redirect EMI back to ground. This prevents high-frequency noise from spreading through circuit traces. They can be plated with nickel or gold for enhanced conductivity and corrosion resistance.

In applications like wearable electronics, communication devices, or industrial keypads, EMI control must not compromise tactile response. Their reliability and precision make them suitable for compact designs where space for separate shielding enclosures is limited.

Which EMI Shielding Materials Perform Best Today?

Choosing the right EMI shielding material is very important in product design. Different materials offer unique conductivity, durability, and flexibility characteristics.

- 1. Stainless Steel – A popular choice for metal domes due to its high strength, corrosion resistance, and decent conductivity. It provides a balance between mechanical durability and EMI attenuation.

- 2. Nickel-Plated Copper – Offers exceptional conductivity and is widely used in sensitive devices where superior EMI reflection is required.

- 3. Aluminum Foil Laminates – Lightweight and easy to apply, suitable for flexible enclosures or array backings.

- 4. Silver-Plated Films – Used in advanced EMI shielding applications where ultra-low resistance and strong reflective capabilities are needed.

- 5. Conductive Fabrics – Ideal for flexible circuits or wearable devices that require shielding without adding rigidity.

The performance of these materials depends on how they are integrated into the overall structure. In many cases, combining conductive adhesive layers or grounding patterns enhances the shielding effect further.

What Is the Best EMI Shielding Material for Compact Devices?

In compact electronic products, such as wearables or smartphones, every millimeter counts. The best EMI shielding material must combine lightweight structure, high conductivity, and minimal thickness.

Nickel-plated stainless steel domes is very thin, yet durable, corrosion-resistant, and provides strong shielding performance. Their magnetic properties also help suppress both electric and magnetic field interference.

For flexible designs, silver-coated polymer films perform well. They can be patterned precisely and bonded onto substrates with conductive adhesives. These films reflect and absorb EMI across a broad frequency range while keeping the assembly ultra-light.

When thermal performance matters, copper foil composites come into play. They spread heat evenly while maintaining excellent shielding.

Compact devices often use a combination of domes, films, and grounding adhesives to create layered EMI protection. The goal is to achieve the best electrical contact with the lowest added weight and thickness.

How Does EMI Shielding Enclosure Design Affect Signal Stability?

A well-designed EMI shielding enclosure determines how effectively a product can resist electromagnetic noise. The structure must not only cover sensitive components but also ensure continuous grounding throughout.

Enclosures made from conductive materials like aluminum or nickel-plated steel act as Faraday cages. They block both incoming and outgoing interference.

Incorporating metal dome arrays or grounded snap domes into the enclosure adds extra protection. Each dome functions as a micro-contact point, helping to maintain continuous conductivity between layers.

In modern electronics, EMI shielding enclosures are becoming thinner and lighter, yet more precise. With the right design, they stabilize signal flow, prevent data errors, and protect against environmental fluctuations. The smoother the grounding and the tighter the shielding, the more stable the overall performance.

How to Evaluate EMI Shielding Material Performance Quickly?

Testing EMI shielding material performance is vital before mass production. A quick way to assess shielding effectiveness is through shielding effectiveness (SE) testing, typically measured in decibels (dB).

- Conductivity Testing – Higher conductivity usually means better EMI performance.

- Thermal Cycling – Testing materials under repeated temperature changes ensures they maintain stable conductivity and structural integrity.

- Adhesion and Flexibility Tests – For flexible circuits or dome arrays, these tests check whether the shielding material remains consistent after bending or stress.

- Frequency Sweep Measurements – Evaluate how well the material performs across low and high frequencies, as EMI sources vary by application.

By using standardized tests early, fast evaluation saves time, reduces rework, and ensures predictable performance once production begins.

Conclusion:

EMI shielding metal domes, arrays, and enclosures play a vital role in preserving signal integrity, improving durability, and enhancing user experience.

Custom designs, reliable materials, and proper enclosure planning all contribute to stronger EMI resistance. Whether it’s a high-end medical device or an everyday consumer gadget, precise shielding design can mean the difference between smooth operation and signal chaos.

If you’re looking for high-quality EMI shielding metal dome solutions, or need assistance with your next EMI design project, reach out to our experts at sales@metal-domes.com