Metal dome for remote control is a small, snap-action component used inside the keypad to provide precise tactile feedback when a button is pressed. Acting as the core of a metal dome switch or tactile dome switch, it ensures a crisp “click” feeling and reliable electrical contact on the dome switch PCB.

What Makes a Metal Dome Ideal for Remote Control Applications?

Metal domes are engineered for precision and reliability. The core reason they excel in remotes is their tactile consistency. When a user presses a button, the dome collapses and returns to its original shape, producing a sharp “click” that confirms input.

Many remote controls see thousands of presses over their lifespan. A metal dome switch can handle this constant usage without performance drop, unlike rubber-only buttons which may wear out or lose tactility.

Moreover, metal domes are compact and lightweight, making them suitable for sleek, modern remote designs. They require minimal travel distance to actuate, reducing hand fatigue and providing a premium feel.

In addition, they conduct electricity reliably when pressed, ensuring consistent signal transmission to the device. This precision is critical in devices like garage door openers, media controllers, and smart home systems.

How Does a Metal Dome Switch Enhance Remote Control Feel?

The tactile response of a metal dome is unmatched. When pressed, it collapses and snaps back, producing a distinct, audible click. This combination of touch and sound provides instant feedback, giving users confidence that the button has been successfully activated.

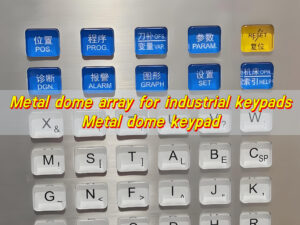

It makes simple interactions feel satisfying, elevating the user experience. Even in devices where precision is crucial, such as medical remotes or industrial controllers, metal domes ensure consistent performance under repeated use.

The snap action also reduces accidental presses. A slight tap triggers the dome, but it prevents minor, unintended contacts from sending signals.

Metal dome switches can be designed with varying stiffness. Softer domes require less force, ideal for users with limited hand strength. Firmer domes provide a pronounced click for those who enjoy tactile feedback.

How to Select the Best Metal Dome for Remote Control?

Choosing the right metal dome requires attention to several factors. First, consider dome size and shape. Larger domes provide more tactile response, while smaller domes fit in compact remotes without compromising functionality.

Next, evaluate the actuation force. This is the amount of pressure needed to collapse the dome. It should match the remote’s design intent: light presses for handheld convenience, firmer presses for intentional control.

Material quality is also essential. Stainless steel is popular for its resilience and corrosion resistance. Some high-end applications use coated metal for enhanced conductivity and longevity.

The mounting method is another consideration. Domes can be adhesive-backed or integrated into a PCB design, depending on the remote’s internal layout.

Finally, always test for life cycle durability. A dome should endure tens of thousands of presses without noticeable wear.

How Does a Dome Switch Button Work Inside a Remote Control?

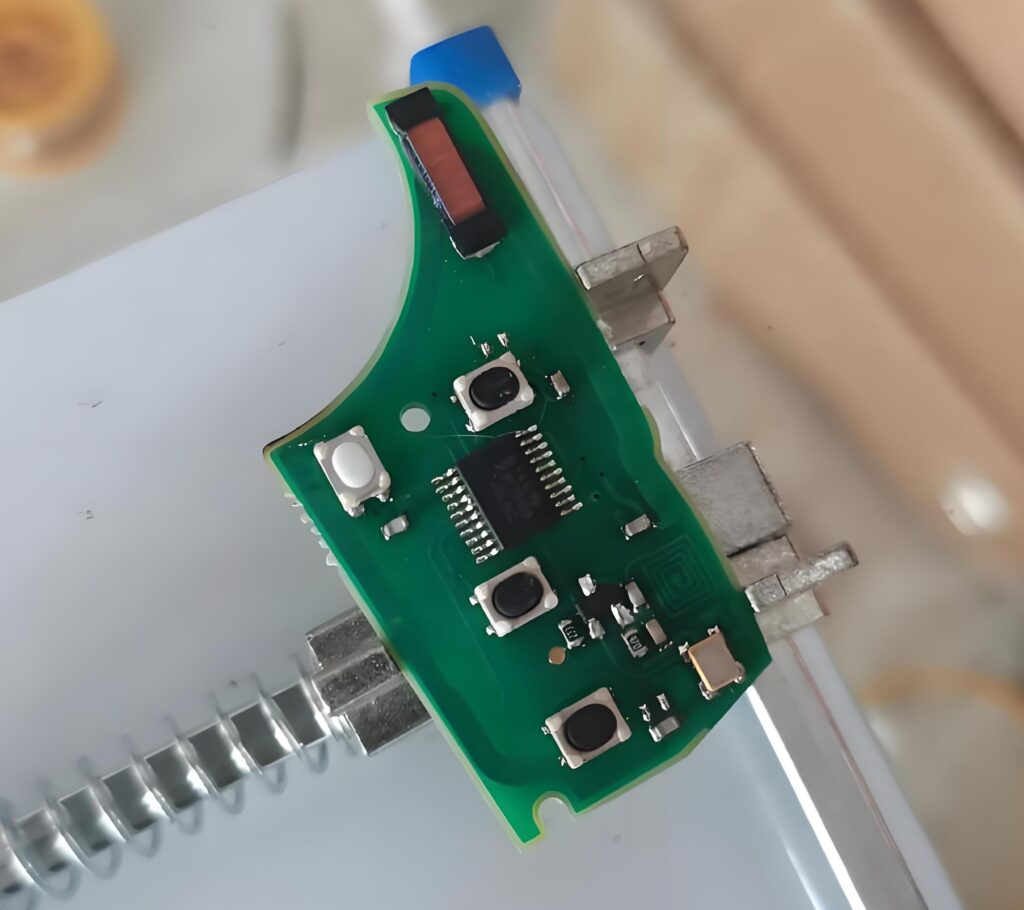

Inside a remote, the dome switch button sits above a circuit contact point. Pressing the button collapses the dome, bridging the conductive surfaces and completing the circuit. This action sends an electrical signal to the remote’s processor, which then triggers the desired function.

The beauty of this design lies in its simplicity. The dome provides both mechanical feedback and electrical contact in one compact component. After release, the dome springs back to its original shape, ready for the next press.

Snap dome buttons are engineered for repeatability. Each actuation is consistent, with predictable travel distance and force.

Moreover, the dome’s metal construction ensures minimal resistance and reliable conductivity. Unlike rubber-only buttons, which may degrade or soften over time, metal domes maintain uniform response even after prolonged use.

What is the Role of a Dome Switch PCB in Remote Control Design?

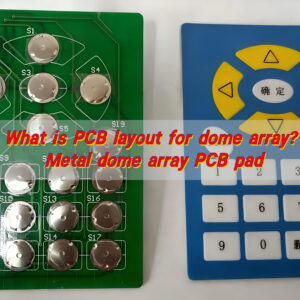

The dome switch PCB serves as the foundation for metal dome integration. It is a printed circuit board designed specifically to accommodate the domes, providing precise placement, electrical pathways, and durability.

The PCB ensures that each dome aligns perfectly with the circuit contact. This precision prevents misfires, reduces electrical resistance, and guarantees reliable performance. In addition, the PCB can include traces, pads, and vias optimized for the dome’s mechanical and electrical requirements.

High-quality dome switch PCBs also enhance product longevity. By securing the domes firmly and protecting traces from stress, the PCB reduces wear and tear.

What Affects Dome Switches Lifespan in Remotes?

Several factors influence how long dome switches remain functional. First is material quality. Poor-grade metal may corrode or lose elasticity, reducing tactile feedback. High-quality stainless steel or coated alloys extend lifespan significantly.

Next, actuation force plays a role. Domes pressed beyond their recommended force can deform or fail prematurely.

Environmental conditions also matter. Excessive moisture, extreme temperatures, or dust can interfere with dome performance. Some domes are specially coated to resist these conditions, ideal for outdoor or industrial remote controls.

The design of the PCB and housing affects durability too. A misaligned dome may experience uneven pressure, causing stress points and early wear.

Finally, user behavior contributes. Frequent, rough pressing or holding buttons down continuously can shorten lifespan.

What’s the Difference Between a Metal Dome and Rubber Dome Switch?

Metal domes and rubber dome switches serve similar purposes but differ in feel, durability, and performance. Rubber domes rely solely on the elasticity of the rubber material to provide tactile feedback. They are quiet, inexpensive, and easy to mold but may degrade over time, losing their clickiness.

Metal domes, by contrast, provide both mechanical and electrical action. Their snap action offers distinct tactile and audible feedback, making them feel more precise and premium. They withstand higher actuation cycles without losing performance.

Rubber domes often require thicker travel distance to achieve a satisfying feel, which can make buttons feel soft or mushy. Metal domes, even with minimal travel, produce a crisp response.

While rubber domes are cost-effective for simple devices, metal domes excel in user-centric products, premium remotes, and environments demanding longevity.

Can Metal Dome Switch Keyboards Be Customized for Remote Controls?

Absolutely. Dome switch keyboards are highly adaptable for remote control applications. BEST Technology can adjust dome stiffness, travel distance, size, and actuation force to meet specific user needs.

For example, a medical remote may require softer domes to reduce hand fatigue, while a high-end TV remote may favor a firmer click for satisfying feedback. Shapes and layouts can also be customized to fit unique device profiles.

Even the PCB layout can be tailored. Multi-layer PCBs, custom trace routing, and dome placement optimization allow for compact, ergonomic remote designs.

Customization ensures the remote feels intentional, premium, and tailored to the brand’s user experience goals.

Conclusion:

Metal domes redefine the way remote controls feel and perform. Their tactile snap, durability, and precision make them ideal for modern devices. Whether for consumer electronics, medical devices, or industrial controls, metal domes elevate user experience, outperform rubber alternatives, and offer extensive customization potential.

To source high-quality components or explore custom metal dome solutions, please contact us directly at sales@metal-domes.com