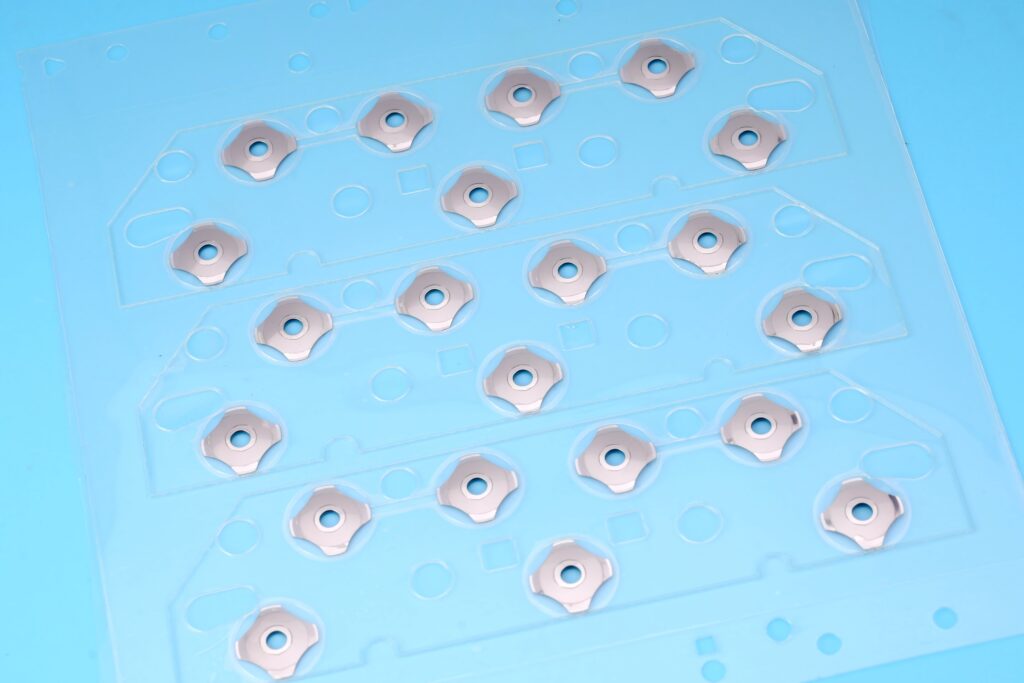

A flexible dome array, also called a metal dome array, is a thin PET sheet with metal domes that provide tactile feedback when pressed. Each dome completes an electrical circuit, creating a crisp “click” feel. Thanks to its flexible structure, it’s easy to mount on curved or compact devices. Widely used in consumer electronics, automotive panels, and medical devices, it ensures reliable performance and a satisfying touch experience.

What Is a Flexible Dome Array in Electronic Design?

A flexible dome array is a thin sheet containing several metal domes, each acting as a small tactile switch. When pressed, the dome collapses and creates an electrical contact with the circuit beneath. Once released, it instantly returns to its original shape, ready for the next actuation.

You can find these arrays inside remote controls, medical devices, wearable gadgets, and industrial panels. They combine tactile precision, durability, and low profile.

Unlike mechanical keys, flexible dome arrays rely on metal domes mounted on flexible PET or polyimide films. The material gives them adaptability and reliability. The domes, usually stainless steel or nickel-plated brass, offer crisp tactile feedback.

In short, a flexible dome array transforms user touch into electrical signals efficiently. It’s compact, responsive, and built for longevity.

What Is a Flexible Dome Array Used For?

Flexible dome arrays play a vital role across industries. They are used wherever tactile feedback and compact size are critical. You can see them inside medical diagnostic equipment, mobile phones, smartwatches, and car dashboards.

They bridge the gap between human input and electronic control. Each dome acts like a miniature metal dome switch, which responds with consistent force. Because of their low actuation force and stable output, they’re preferred for control panels that require frequent operation without fatigue.

In consumer electronics, dome arrays support quick, reliable key presses. In industrial devices, they survive harsh use without losing feedback consistency. In the medical field, their sealed design resists moisture and disinfectants.

Simply put, flexible dome arrays deliver precision control with tactile satisfaction, no matter the environment.

How Flexible Dome Arrays Enhance Wearable Electronics?

Wearable devices demand comfort, reliability, and lightweight performance. A flexible dome array meets all these requirements perfectly.

In smartwatches and fitness trackers, the array sits beneath the button layer, offering instant response even with minimal pressure. The flexible sheet conforms to curved surfaces, which is essential for compact wearables.

Beyond mechanical performance, these arrays help reduce power consumption. They require only a gentle touch to actuate, minimizing user effort while extending battery life. Their resistance to sweat and moisture also prevents corrosion, which is a common issue in portable devices.

Another advantage lies in custom tactile design. BEST Technology can adjust the dome size, shape, and actuation force to match the device’s personality. Some brands prefer a soft, quiet click, while others choose a sharper feedback to enhance the user’s perception of quality.

What Affects the Lifespan of a Metal Dome Array?

A metal dome array can last from hundreds of thousands to over a million cycles — but that depends on several factors.

- Material quality stands first. Stainless steel domes typically offer better fatigue resistance than copper or brass domes. The plating process also matters; nickel or gold plating protects the metal from oxidation.

- Design precision is another key. If the dome’s curvature or force value isn’t accurate, it can cause uneven stress distribution.

- Then comes environmental exposure. Humidity, temperature, and dust all play a part. For example, high humidity may cause corrosion if the dome isn’t properly sealed. Meanwhile, excessive force during operation may deform the dome prematurely.

- Adhesive quality on the flexible sheet can’t be overlooked either. If it’s weak, the dome can shift, misalign, or lose contact accuracy.

- Lastly, assembly practices matter. Using clean, controlled environments prevents contaminants from entering the contact area, preserving switch sensitivity.

Every detail — from metal choice to assembly care — directly affects the lifespan of a metal dome array.

What Improves Lifespan in a Metal Dome Array?

To extend lifespan, attention to design, materials, and handling is crucial.

- Choosing high-quality stainless steel domes provides the foundation for endurance. They resist deformation and deliver stable tactile performance even after repeated presses.

- Surface plating with nickel or gold enhances conductivity and shields against oxidation. Gold, though more costly, offers unmatched stability for low-voltage circuits.

- BEST Technology also enables engineering of precise actuation force levels – not too high to cause stress, not too low to lose feedback.

- Proper venting in the array layer prevents trapped air from affecting tactile feel. Without vent holes, pressure builds up, slowing the dome’s recovery speed.

- In addition, clean assembly environments keep out contaminants. Dust or oil particles on the contact surface can degrade performance.

When these factors are optimized, a metal dome array easily reaches a lifespan beyond a million cycles, ensuring consistent user satisfaction.

How to Use a Flexible Dome Array on a Membrane Switch?

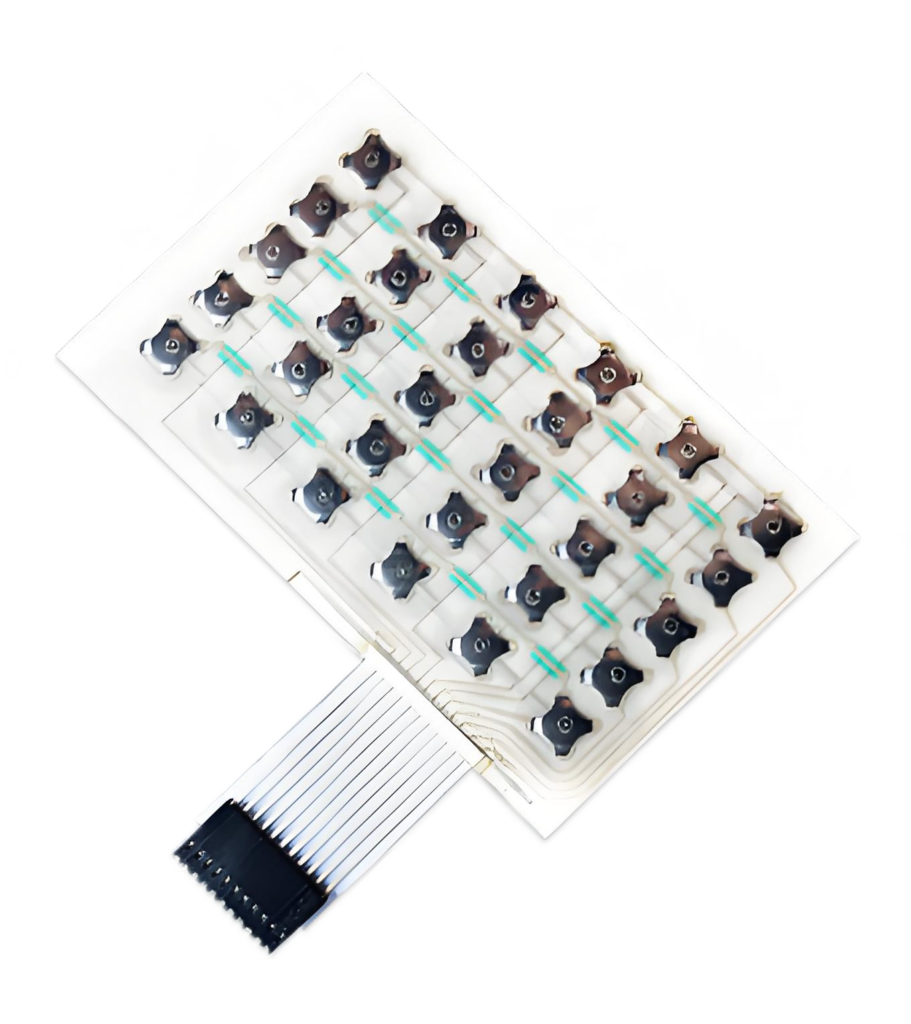

Integrating a flexible dome array into a membrane switch enhances both tactile feedback and electrical reliability.

In a typical membrane switch, the array sits between the top graphic overlay and the circuit layer. When the user presses a key, the dome collapses, bridging the contact points on the circuit beneath. Once released, it pops back, breaking the contact and resetting the key.

The dome array replaces the standard printed spacer structure, improving the tactile sensation without increasing thickness.

When combined with LED backlighting or embossed graphics, the switch feels modern and premium. Moreover, using a flexible PET or polyimide base allows the entire assembly to bend or curve, which suits automotive panels, handheld devices, or medical instruments.

Installation is straightforward. The adhesive backing on the dome array bonds it firmly to the circuit sheet. Positioning accuracy is essential, so alignment holes or guide marks are usually printed.

Are Dome Switches Suitable for Flexible PCBs?

Yes, dome switches work perfectly on flexible PCBs. Flexible PCBs, often made of polyimide or PET, share the same flexibility as dome arrays.

When mounted on flexible circuits, snap dome switches deliver fast actuation and reliable signal transmission. However, the circuit traces must be positioned precisely to align with each dome’s contact point.

The flexibility also demands proper strain relief design. Excessive bending near the contact area can stress the copper traces, so reinforcement with stiffeners may be needed.

This setup benefits applications like foldable devices, medical sensors, and compact controllers. It reduces size and weight without sacrificing tactile performance.

In short, dome switches are not just suitable — they’re ideal for flexible PCB assemblies where space, feedback, and reliability all matter.

How to Customize Metal Dome Arrays?

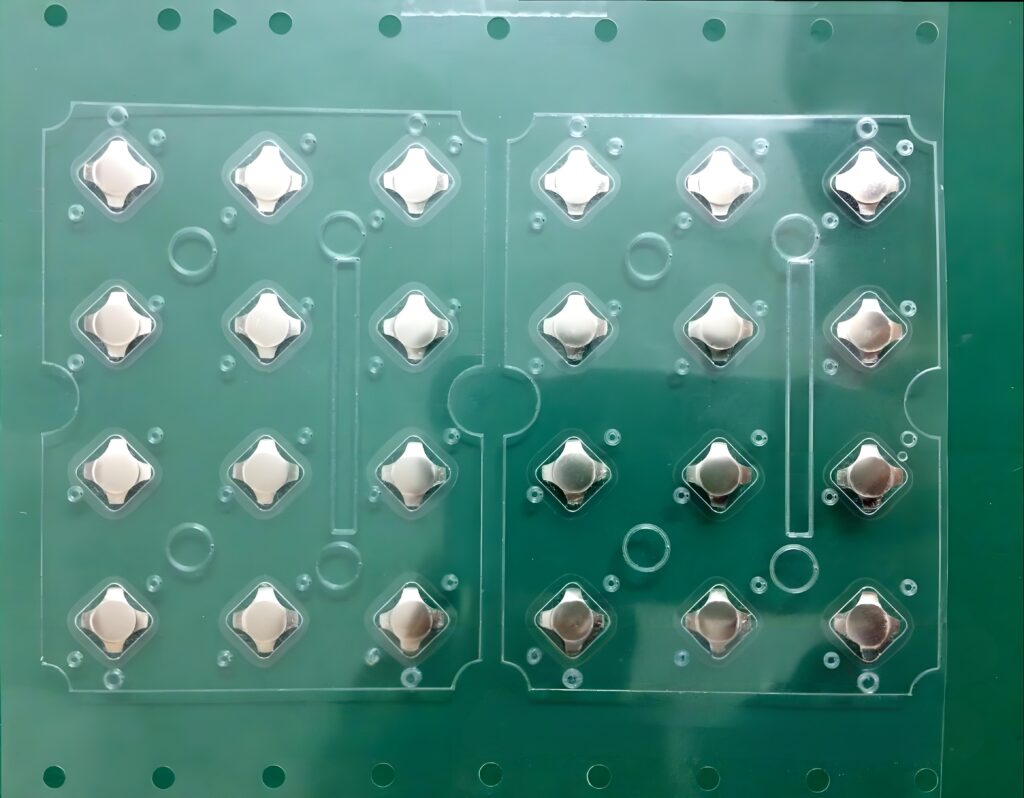

The shape of the dome can vary — round, cross, triangle, or four-leg. Each type offers a different tactile feeling and actuation force. For example, cross domes give a sharp click, while four-leg domes provide more stable feedback.

Force range can be adjusted between 100g to 600g or more. Light-touch designs suit handheld electronics, while high-force domes serve industrial equipment where accidental activation must be avoided.

Size options are wide, from 4mm micro-domes to 20mm units for large buttons. BEST Technology engineers can also modify the travel distance — how far the dome moves before contact — to fine-tune the feel.

Surface finish is another customization area. Nickel, gold, or silver plating changes conductivity and appearance. For demanding environments, protective coatings prevent corrosion or humidity damage.

At Best Technology, our engineers work closely with clients to adjust each specification precisely. Whether for consumer gadgets, automotive panels, or medical systems, a customized metal dome array ensures the perfect balance of tactile comfort and durability.

Conclusion:

At Best Technology, we specialize in designing and producing metal dome arrays and membrane switch assemblies for diverse applications. Our production follows strict quality systems, including ISO9001, ISO13485 for medical, IATF16949 for automotive, and AS9100D for aerospace.

Each step, from dome plating to laser cutting of PET films, is controlled by our MES system, ensuring complete traceability. Our engineering team collaborates with customers to design arrays with the right tactile response, durability, and actuation force.

If you’re developing a product that requires accurate touch response and lasting quality, Best Technology can support you with custom metal dome arrays tailored to your needs.

For inquiries or design consultation, reach out to sales@metal-domes.com