Power off the keyboard and remove the case. Lift the membrane to expose the metal dome keypad. Use tweezers to take out the worn dome and clean the contact pad. Place a new dome in the same position, reassemble, and test for a sharp, even click.

What is a metal dome?

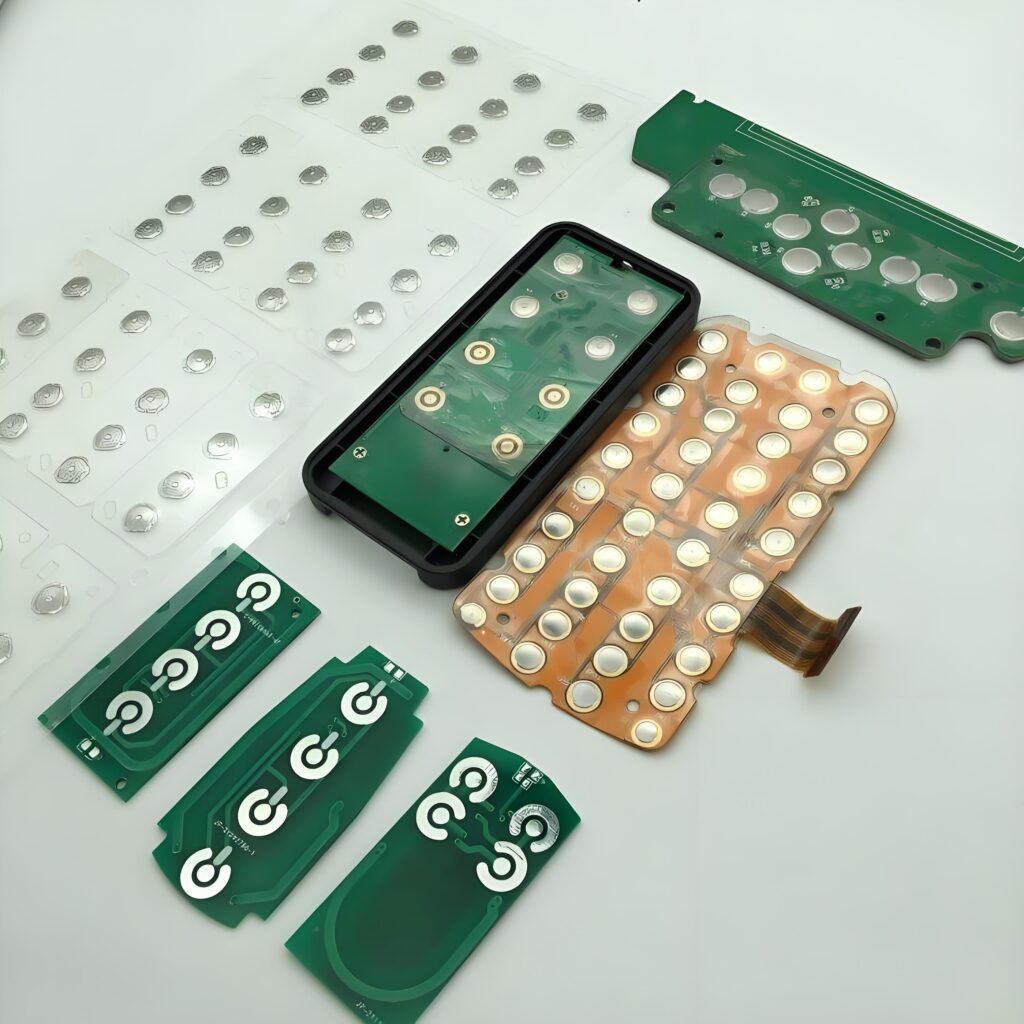

A metal dome is a small, spring-like disc stamped from thin stainless steel. In a metal dome keypad, each dome sits between the printed circuit board (PCB) and the top overlay. Pressing a key forces the dome to collapse. The dome touches the circuit below, completes the electrical path, and then pops back to its original shape.

This quick action creates a sharp tactile click. That click is what users feel and hear when they press a key. Because stainless steel resists corrosion and fatigue, a dome can endure millions of actuations before wearing out. This makes the design perfect for industrial controls, consumer electronics, and even medical equipment.

What causes the metal dome to have a poor click feel?

Over time, a metal dome keyboard may lose its lively response. The reasons can vary:

- Metal fatigue: After countless presses, the dome’s spring force can weaken.

- Dust or debris: Small particles trapped under the overlay reduce movement and dull the snap.

- Moisture or oxidation: Humidity can create a thin film on the contact points, leading to inconsistent feedback.

- Improper assembly: If the dome was slightly misaligned during manufacturing or a past repair, it may not flex as designed.

The positive side is that most of these issues can be fixed. A careful cleaning or a replacement dome often restores the original crisp feel.

How to fix the problem of poor feel of metal dome buttons?

Before replacing a dome, try simple solutions first.

- Clean the surface: Power off the keyboard. Remove the key overlay and gently wipe the domes with a lint-free cloth. Use isopropyl alcohol if grease or residue is present.

- Check alignment: A dome that shifted out of position may need only a slight adjustment. Align it so the legs or edges match the original seat.

- Inspect for wear: If a dome looks flattened or shows visible cracks, replacement is the best option.

Small maintenance often brings back the satisfying click. If it does not, continue to a full replacement.

Why do membrane keyboards fail?

Many people call metal dome keyboards “membrane keyboards” because they share a flexible top layer. Traditional membrane designs, however, use rubber domes instead of metal. Rubber ages and loses elasticity faster than stainless steel.

Common failure points include:

- Rubber dome collapse: The rubber loses spring tension and no longer provides feedback.

- Trace wear: Conductive ink on the circuit sheet can break after long use.

- Moisture damage: Liquids seep between layers and corrode the contacts.

Compared to rubber versions, a metal dome keypad offers a much longer lifespan and stronger tactile feel, which is why many industrial and medical devices choose metal over rubber.

Is it possible to repair a membrane keyboard?

Yes, repair is possible and often practical. For rubber membranes, you can sometimes restore conductivity by cleaning contacts or applying conductive paint. But the fix is temporary.

With a metal dome keyboard, repair is far more effective. Stainless steel domes are individual parts. You can remove a worn dome and install a new one without replacing the entire keypad. That makes maintenance cost-efficient and sustainable.

How to replace switches on a membrane keyboard?

Replacing a metal dome in a metal dome keypad follows a clear process. Prepare a clean workspace with good lighting and have the right tools ready: tweezers, a precision screwdriver, a lint-free cloth, and replacement domes.

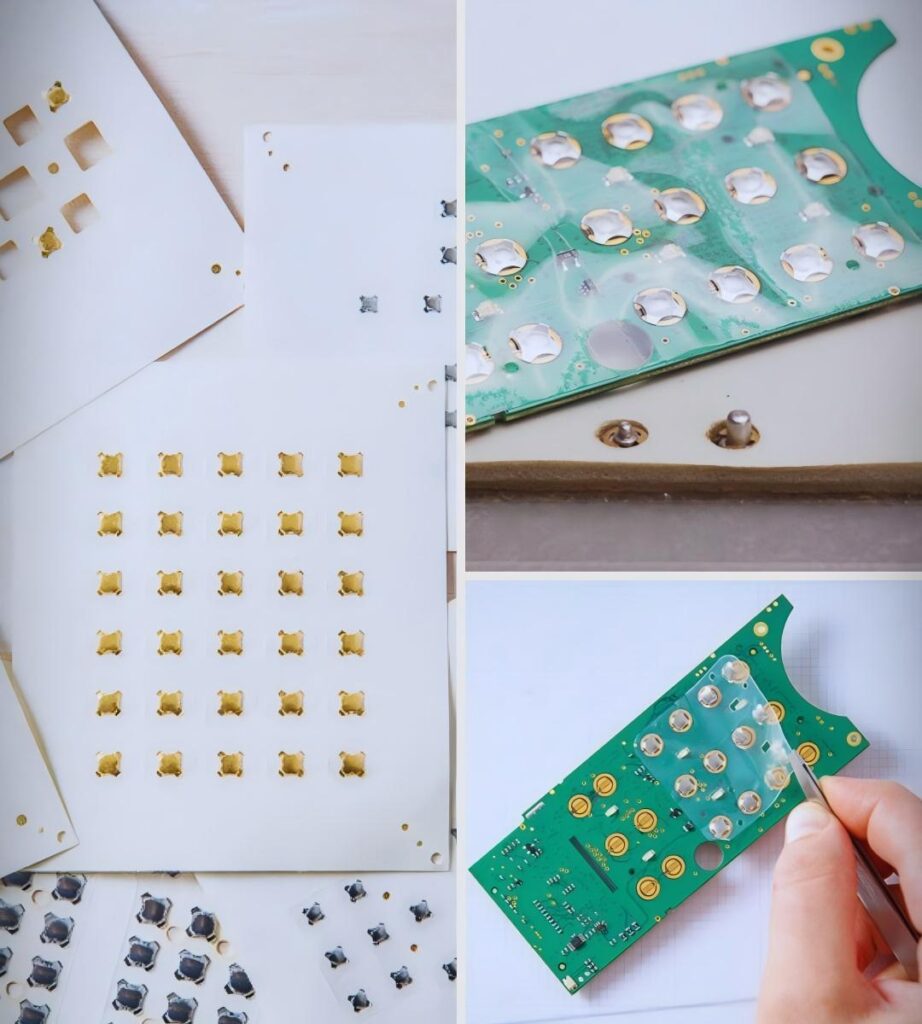

- Step 1: Power Down and Disassemble

Unplug the keyboard or remove its battery. Unscrew the back cover carefully. Keep the screws in a container to avoid loss.

- Step 2: Lift the Overlay

Gently peel back the top membrane layer. Work slowly to avoid tearing the adhesive. Use a plastic spudger if needed.

- Step 3: Locate the Faulty Dome

Identify the dome with weak or no feedback. Check for visible dents, scratches, or dirt.

- Step 4: Remove the Old Dome

Use tweezers to lift the damaged dome straight up. Avoid bending neighboring domes.

- Step 5: Clean the Contact Area

Lightly wipe the PCB pad with a cloth dampened with isopropyl alcohol. Allow it to dry.

- Step 6: Place the New Dome

Position the new dome so its legs or orientation tabs match the original design. Ensure it sits flat.

- Step 7: Reassemble and Test

Lay the overlay back in place and screw the keyboard together. Test the key to confirm a crisp, even click.

Patience is important. Rushing can warp the membrane or misalign the dome.

What is the lifespan of a membrane keyboard?

Lifespan depends on materials and usage. A standard rubber-dome keyboard lasts about five million keypresses. A metal dome keyboard can exceed ten million cycles thanks to stainless steel’s resilience.

Environmental care extends life even more. Keep the device dry, avoid extreme temperatures, and store it in a dust-free area when not in use.

How to replace a mechanical keyboard switch?

Some people use mechanical keyboards alongside metal dome keypads. The repair steps differ.

- Remove the Keycap: Use a keycap puller to lift the cap straight up.

- Desolder the Switch: Flip the board and heat the solder joints with a soldering iron. Remove the old switch.

- Insert the New Switch: Push the replacement into the plate and PCB.

- Resolder and Test: Solder the pins carefully, then test for smooth actuation.

While mechanical switches and metal dome switches both provide tactile feedback, their maintenance methods are unique. Knowing the difference helps prevent damage.

Conclusion:

Metal dome keypad combines a sharp tactile feel with exceptional durability. Over time, a single dome may lose its snap, but cleaning or replacing it restores the crisp click. By following careful steps—powering down, disassembling, cleaning, and fitting a new dome—you can extend the life of a metal dome keyboard for years.

For expert guidance or to order high-quality replacement domes, contact sales@metal-domes.com