What is a stainless steel dome?

Stainless steel domes are thin, elastic element made of stainless steel, offering stable springback properties. Typically 0.05-0.1 mm thick, it is pressed to create a contact at its center point, creating a conductive connection between the PCB and the circuit. Its diameter ranges from 3 to 20 mm, and it can be plated with gold or nickel, achieving contact resistance in the ohm range.

It is primarily used in applications requiring high-precision tactile feedback, such as mobile phone buttons, membrane switches, PCBs, and medical devices. Common shapes include circular, cross, and triangular. Special materials can withstand a pressure of 6,000 g and have been tested to last up to one million cycles.

Why use stainless steel domes in electronics?

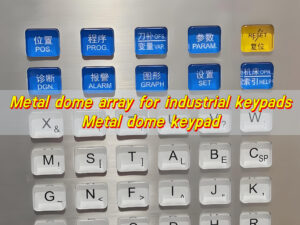

The use of stainless steel domes in electronic products is primarily due to their corrosion resistance, strength, and cost advantages. Their smooth action provides consistent tactile feedback, which users trust. Products such as remote controls, medical instruments, and industrial keypads rely on this snap.

- High Corrosion Resistance

Stainless steel offers excellent corrosion resistance, making it suitable for humid and chemical environments, extending the lifespan of snap clasps. For example, using stainless steel in mobile phone snap clasps prevents oxidation and ensures stable circuit conduction.

- High Mechanical Strength

Stainless steel snap clasps have a wide hardness range (350HV-550HV), and through precision stamping, they can meet the needs of various applications. For example, snap clasps in automotive electronics must withstand complex vibrations, and the high elastic modulus of stainless steel effectively reduces deformation.

- Cost and Processing Advantages

Stainless steel costs less than precision alloys, reducing production costs. While newer materials such as amorphous alloys offer improved performance, stainless steel remains the dominant material.

What makes a metal dome structure more durable?

Stainless steel stands up to corrosion and mechanical stress. A well-designed metal dome structure spreads force evenly to avoid weak points. Precise stamping keeps every dome uniform so it performs reliably through millions of cycles.

This is primarily achieved through the following technical optimizations:

- Asymmetric dome design: By adjusting the dome thickness distribution and curvature radius, local stress concentration is avoided, increasing fatigue life by over 100%.

- Multi-curvature dome design: Using a multi-level curvature structure, the fatigue failure time of a traditional dome is extended from 3 million cycles to 6 million cycles.

- Upgraded contact material: Silver alloy contacts replace copper alloy, increasing electrical life by 50%. Gold-silver alloy contacts also achieve a lifespan of 5 million cycles.

- Improved dome materials: Nickel-chromium alloy dome steel undergoes heat treatment, significantly enhancing fatigue resistance. SUS304 stainless steel dome with gold plating offers a lifespan of up to 5 million cycles.

Metal Dome technology combines a stainless steel dome with gold plating to maintain a lifespan exceeding one million cycles, adapting to the trend of compact electronic devices.

How does a metal dome switch improve feedback?

Metal dome switch gives a sharp tactile feel and an audible click when pressed. The dome rebounds instantly, ready for the next command.

Adding a silicone gasket beneath the dome or adjusting the internal support structure can disperse the impact of pressing, reducing mechanical fatigue. For example, automotive steering wheel switches feature an IP67-rated sealing design, guaranteeing a lifespan of over 5 million cycles even in extreme environments.

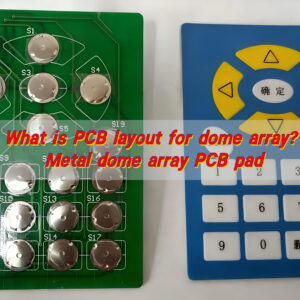

Which stainless steel domes fit PCB designs best?

Different boards need different shapes. The most suitable stainless steel dome for PCB design needs to be selected according to specific needs. Round, four-leg, and triangle domes can match almost any printed circuit layout. Low-profile options suit slim devices, while larger domes handle heavier actuation.

- General PCB Applications:

304 Stainless Steel: Features strong corrosion resistance (1000 hours of salt spray test life), 200 HV hardness, and excellent impact resistance (no deformation after a 50G impact), making it suitable for general PCB design.

- High-Temperature or Corrosion-Resistant Environments:

316 Stainless Steel: Contains molybdenum, increasing acid and alkali resistance by 50%, making it suitable for medical disinfection (no corrosion after 500 hours of immersion in 75% alcohol) and coastal high-salt environments. However, its cost is 30% higher than 304.

- Special Applications:

Nickel-Gold Alloy Edge Binding: The nickel layer provides strength, while the gold layer enhances conductivity and corrosion resistance. With a wear resistance of up to 50,000 insertion and removal cycles, it is suitable for high-frequency use.

- Mechanical Strength Requirements:

Gold Plating: Surface gold plating improves conductivity and wear resistance, but a gold layer thicker than 0.5?m can increase brittleness.

When selecting a suitable material, consider the PCB’s operating temperature, corrosion resistance, mechanical load, and cost.

How to maintain stainless steel domes for long life?

Maintaining a stainless steel dome requires careful cleaning, lubrication, and protective measures. Regularly apply cooking oil or specialized grease to contact areas to form a protective film and prevent rust. Avoid contact with strong acids and bases (such as vinegar and soy sauce) to prevent surface corrosion.

Keep domes clean and dry before and after assembly. Avoid harsh cleaners; gentle, non-abrasive wipes work best.

Minor scratches can be repaired by rubbing stainless steel polishing paste in circular motions; serious scratches require professional treatment. Long-term exposure to humidity requires regular application of anti-rust coating. Proper storage prevents moisture damage and supports a long operating life.

Where are stainless steel tactile domes applied?

Stainless steel tactile domes (commonly known as metal domes) are primarily used in the following areas:

- Electronic products: Used in pushbutton switches for devices such as mobile phones and remote controls, replacing traditional silicone buttons to improve operational feel and lifespan.

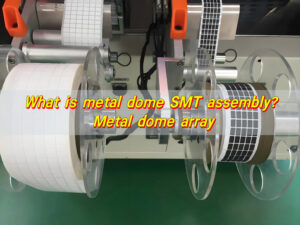

- Membrane switches: Core components used in printed circuit boards (PCBs) or flexible circuit boards (FPCs), they provide circuit continuity through stable spring force and long-lasting tactile feedback.

- Medical devices: Used in the precision machining of surgical instruments (such as scalpels, scissors, and tweezers) to ensure sharpness and durability; they also provide critical mechanical support in implantable devices (such as heart stents and orthopedic plates).

- Industrial equipment: Used in industrial automation equipment, automotive electronics, and other fields, they provide high-precision tactile feedback and stable performance.

How can Best Technology customize stainless steel domes?

Every product has its own demands, and Best Technology treats each project as a one-of-a-kind challenge.

Need a particular actuation force or a unique shape? We can fine-tune every detail. Whether it’s an ultra-low profile sheet metal dome for a slim wearable, a four-leg design for high-speed SMT placement, or a rugged metal dome switch built to survive millions of presses in industrial controls, we match size, thickness, and snap force to your exact PCB layout.

Our manufacturing line uses precision stamping and automated inspection to hold tolerances within ±0.05 mm. Surface treatments and optional plating improve conductivity and resist corrosion, ensuring that each stainless steel tactile dome performs consistently for years. From small prototype runs to large-scale orders, you can count on stable pricing, quick lead times, and reliable global delivery.

Conclusion:

Stainless steel domes combine strength, precision, and a clean tactile response. They enhance user satisfaction, protect circuits, and last through millions of presses. From consumer gadgets to critical medical tools, their value is clear.

For custom stainless steel domes or detailed support, contact sales@metal-domes.com