What is a metal dome structure?

Metal dome is a small, flexible, and highly responsive component made from stainless steel or other spring metals. Shaped into a dome-like structure, it acts as a momentary switch when pressed.

The dome flexes down under pressure and immediately returns to its original shape once released, giving users tactile feedback.

But metal dome structure goes far beyond the dome itself. It’s the entire system that ensures a clean, crisp response in every application—from consumer electronics to military-grade devices.

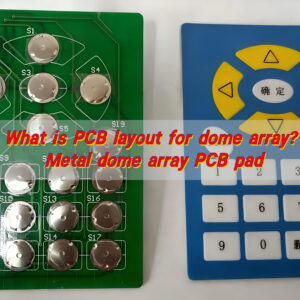

These domes are often part of a larger assembly called a metal dome array, which includes a backing adhesive, PET or polycarbonate film, and a conductive trace.

How are metal domes made?

It starts with ultra-thin, high-grade stainless steel sheets. These sheets are precision-stamped or laser-cut to form the domed shape, then heat-treated to maintain their spring force and endurance.

Depending on the design, BEST Technology can choose different shapes: four-leg, triangle, round, or oblong domes. The forming process is carefully controlled to ensure:

- Uniform force distribution

- High resilience

- Excellent tactile feedback

- Consistent dome height and actuation force

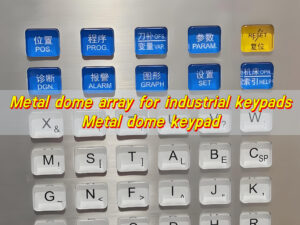

Some designs even feature sheet metal domes layered on switch panels for a more advanced user interface. These domes can be customized with different click forces, dome heights, and diameters to meet specific needs.

How does a metal dome switch work?

When you press a metal dome switch, the dome collapses, making contact between two circuit traces on a printed circuit board (PCB) or flex circuit. Once contact is made, a signal is sent to activate a function. Release the dome, and it snaps back instantly—ready for the next command.

This snapping action not only gives you the satisfying “click” but also ensures the contact is both fast and accurate. The tactile response reduces errors, improves speed, and makes user interfaces far more intuitive.

That’s why metal dome switches are widely used in control panels, medical instruments, and high-end consumer electronics.

Why use metal domes in electronics?

Here’s what sets them apart:

- Tactile Feedback: That clear, crisp click assures users the function has been triggered.

- Durability: High-quality domes can withstand over 1 million actuations.

- Consistency: Whether it’s the 1st press or the 500,000th, response remains reliable.

- Space-Saving: Compared to mechanical switches, domes take up far less space, making them ideal for compact designs.

- Customizable: Click force, size, shape, and actuation profile can all be tailored.

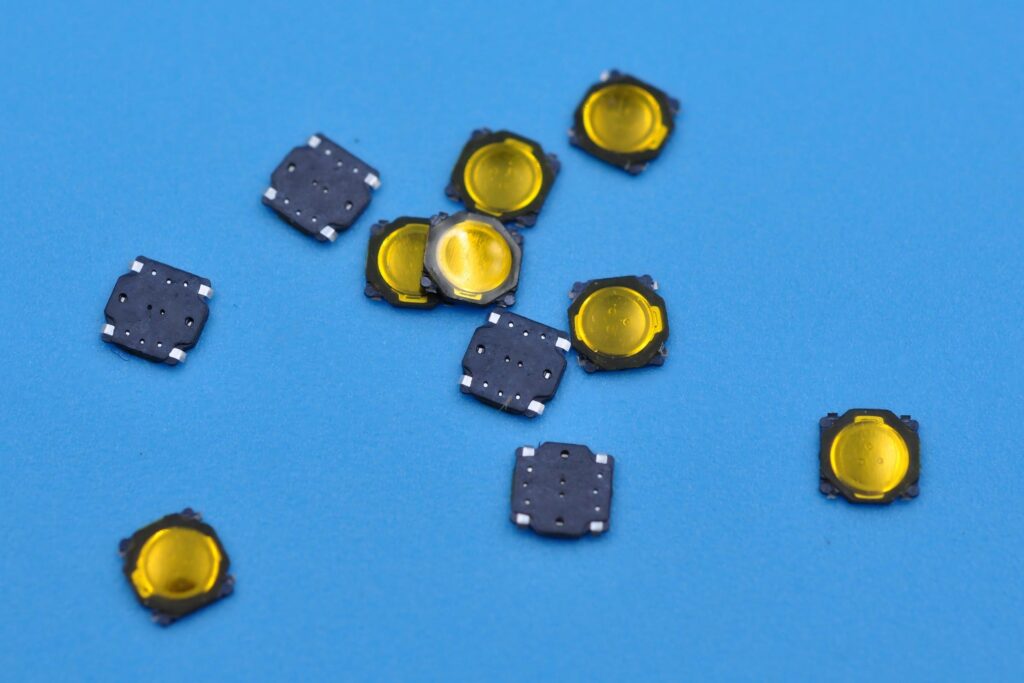

What are the types of metal domes?

Metal domes come in several shapes and sizes. Each serves different functions and offers a unique feel.

- Four-Leg Dome: Offers a high, crisp tactile feel. Excellent for keypads and control panels.

- Round Dome: Most common. Balanced feedback with moderate actuation force.

- Triangle Dome: Compact, used in tight spaces with quick response times.

- Oblong Dome: Designed for larger contact areas and softer feel.

- Custom Domes: Tailored for specific user experiences or environmental conditions.

The choice of dome type depends on several factors, including required click ratio, environment, durability expectations, and space limitations.

How to choose the right metal dome?

Choosing the right metal dome isn’t just about the shape. It’s about performance.

What is the intended application? Medical, industrial, or consumer use will influence design.

How many cycles should the dome endure? Standard domes handle up to 1 million cycles.

What click feel is desired? Some users prefer a soft, smooth actuation; others want a sharp, pronounced click.

What is the available space? Smaller devices need low-profile domes, while larger panels can accommodate higher ones.

How long do metal domes last?

Properly designed dome structure can survive over one million actuations without performance loss.

But the actual lifespan depends on several factors:

- Material Quality: High-grade stainless steel ensures longevity.

- Design Precision: Correct force and dome shape prevent fatigue.

- Environmental Conditions: Extreme temperatures, dust, or moisture may reduce lifespan unless domes are sealed.

- Mounting Surface: A smooth, clean surface helps domes perform at their best.

When combined with a well-designed backing layer, domes not only last long, they remain accurate, reliable, and efficient throughout their life.

Where are sheet metal domes used?

- Industrial Applications: Control systems, factory panels, and rugged devices all rely on domes for instant feedback.

- Medical Equipment: Ventilators, diagnostic machines, and hospital controls use domes due to their accuracy and ease of disinfection.

- Consumer Electronics: Remote controls, keyboards, game controllers, and wearables benefit from their slim profile and responsive feel.

- Automotive Panels: Used in dashboard switches, steering wheel controls, and keyless entry systems.

- Military and Aerospace: Chosen for their reliability in extreme environments, sheet metal domes offer mission-critical performance.

And thanks to their flexible design, dome sheet metal components can be adapted for virtually any application—adding performance and polish to any user interface.

Conclusion:

Metal domes are unmatched in compact switch technology for their construction, durability and speed of response. Whether you call it a metal dome, sheet metal dome, or dome metal, this tiny part plays a big role in making devices smarter, faster, and more responsive.

At Best Technology, we specialize in delivering high-precision metal dome switches, metal dome arrays, and custom solutions tailored to your exact needs.

Looking for a trusted metal dome supplier? Contact us today at sales@metal-domes.com