Metal dome switches for PCB are compact, tactile components that deliver fast, reliable feedback with each press. They offer a crisp click, long life, and slim profile—perfect for high-performance electronics.

Metal dome array holds multiple domes in one sheet for easy, accurate mounting. It speeds up assembly and ensures clean, consistent alignment on the PCB.

What are metal dome switches for PCB?

Metal dome switches are tactile, mechanical contacts designed to complete a circuit when pressed. They’re commonly made from stainless steel and shaped to snap when actuated. This snap gives users a responsive, satisfying click.

On a PCB, these domes are placed over contact pads. When pressed, the dome flexes, touches the pads beneath, and completes the circuit. Once released, it returns to its original shape, ready for the next actuation.

What makes them so valuable? Their ultra-thin profile, long life span, and incredible tactile feel. Whether used in a medical device, control panel, or remote controller, metal dome switches for PCB offer unmatched reliability and performance.

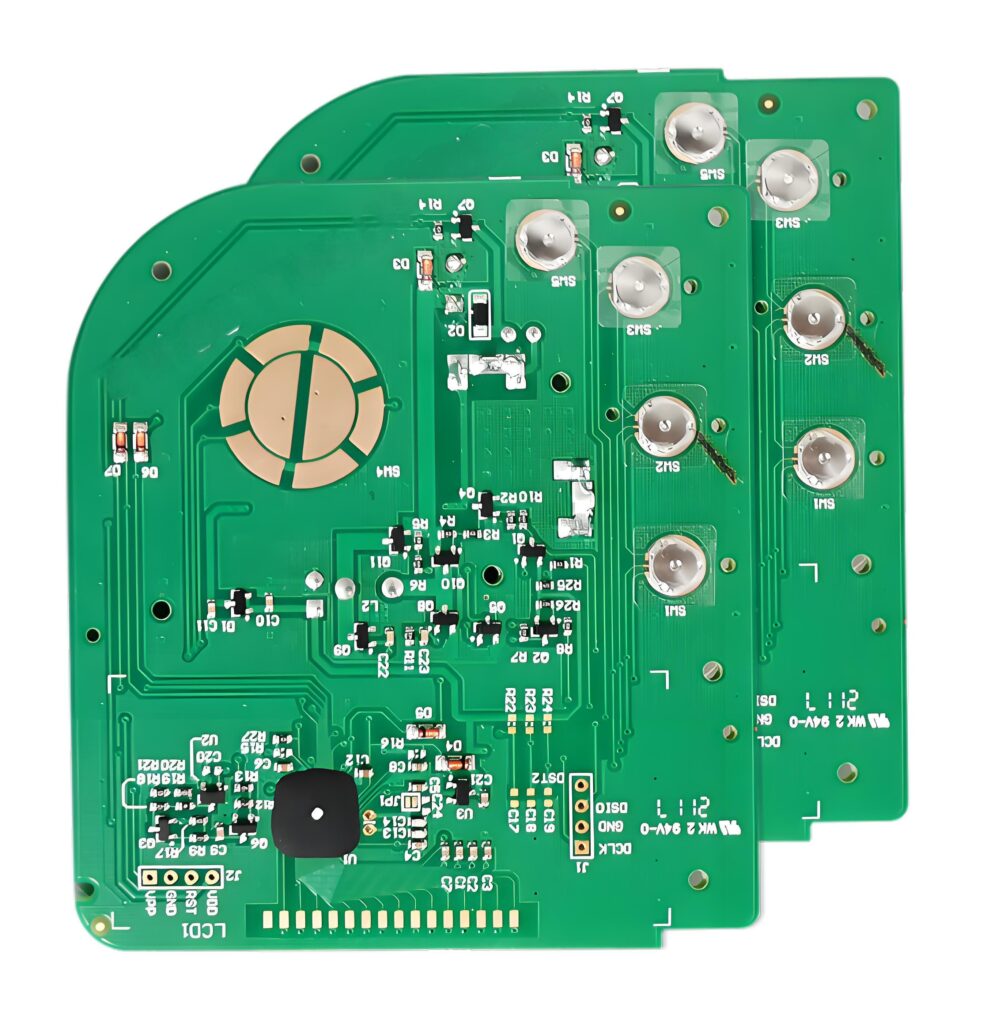

How to mount metal dome switches on PCB?

Mounting a metal dome switch on a PCB might sound complex, but the process is surprisingly simple and highly adaptable. There are two primary methods:

1. Dome Array Sheets:

This is the most common way. Domes are pre-arranged on a PET film or adhesive sheet. The entire array is aligned and pressed onto the PCB. No soldering is needed. The alignment is crucial, but once placed, it stays firmly attached. This method is fast, clean, and cost-effective for mass production.

2. SMT (Surface Mount Technology):

For advanced automation, some domes—especially four-leg domes—are packaged in Tape & Reel. These are placed on the board using pick-and-place machines. It’s perfect for high-speed lines and ensures perfect alignment every time.

Once mounted, a circuit overlay or graphic overlay goes on top. It adds protection and displays labels or icons. Pressing a specific spot on the overlay triggers the dome underneath.

Overall, whether you choose adhesive dome sheets or SMT domes, both methods offer clean mounting, reduced labor, and long-lasting performance.

What makes PCB dome switches better than standard buttons?

Standard push buttons—like tactile rubber switches—might seem more common. But they have their flaws. They’re thicker, often bulky, and wear out faster under frequent use.

Here’s what gives PCB dome switches an edge:

- Tactile Feel: Every press delivers crisp feedback. Users know when they’ve made a successful input.

- Slim Profile: Domes add almost no thickness.

- Durability: High-quality domes can last over 1 million cycles. That’s miles ahead of standard rubber switches.

- Speed: Dome switches respond instantly. There’s no lag or delay.

- Customization: You can choose the actuation force, dome shape, and layout. That level of control just isn’t possible with standard buttons.

In short, dome switches bring a premium experience. Whether you’re building a smart device or industrial equipment, they deliver precision, comfort, and longevity.

How does a tactile metal dome switch work?

Tactile dome switch is built with a preloaded metal dome—often stainless steel—placed above PCB contact pads. The dome acts like a spring. When pressure is applied, it collapses and touches the pad, completing the circuit. When released, it snaps back to its original form.

That sharp, snap-action feel is the tactile feedback. It confirms that the action was successful without needing to look at the device.

Each dome is engineered for a specific force, commonly ranging from 100g to 500g. Want a softer press? Choose a lower force. Need something more robust? Go higher.

The switch is silent in terms of noise, but the physical sensation is clear. That’s why tactile dome switches are often chosen for control panels, handheld remotes, and keypads that require reliable user input.

What is the difference between dome switch and membrane?

Dome switches rely on a physical metal dome to create a crisp, mechanical response. When pressed, the dome collapses and makes contact with the circuit below. This tactile feedback is highly valued in professional equipment, control panels, and precision tools.

Membrane switches, on the other hand, use pressure-sensitive layers with no moving parts. When you press down, the top layer connects with the bottom, activating the circuit. It’s a smooth action—but lacks that satisfying tactile response.

Durability also varies. Metal dome switches are built for endurance, often exceeding one million cycles without failure. Membrane switches, while more affordable, tend to wear out faster—especially under heavy use.

When it comes to thickness, both are slim, but dome switches still lead with their ultra-low profile. They also offer more customization, allowing engineers to fine-tune the actuation force and layout. Assembly with dome arrays or SMT makes integration clean and efficient.

Cost-wise, membrane switches are cheaper upfront, making them suitable for disposable or low-use products. But for applications where reliability, feel, and long-term value matter, metal dome switches for PCB are the smarter investment.

In short, membrane switches are a cost-saving choice. Dome switches are a performance-driven solution.

Can dome switches be used in keyboards?

What many call a “dome switch keyboard” uses metal domes beneath each key. Unlike rubber dome keyboards that feel mushy and unresponsive, dome switch keyboards offer a clear, crisp click.

In compact or custom-built keyboards—especially in industrial settings—metal dome switches are the gold standard. They offer:

- Precise actuation

- Lower profile designs

- Custom key force options

- High resistance to wear and tear

Because of their tactile performance, these switches are also popular in medical devices, handheld scanners, and rugged tablets.

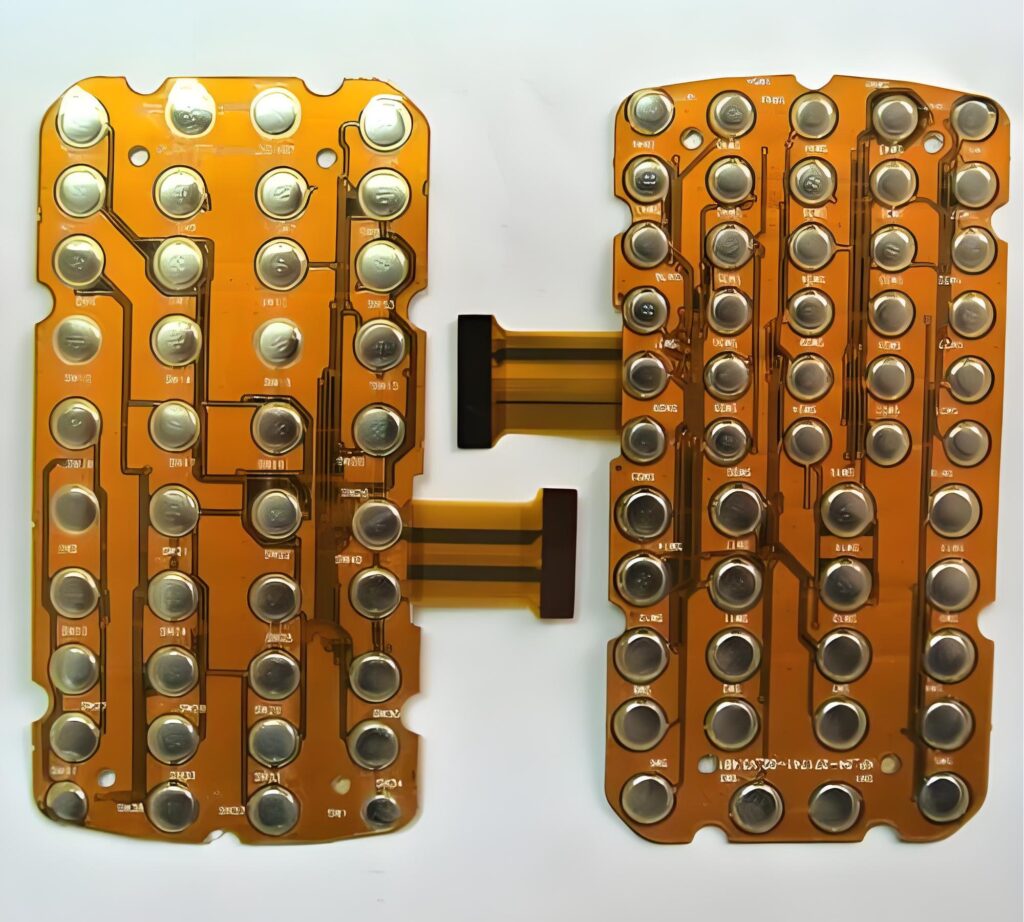

What is a metal dome array in PCB design?

Metal dome array is a sheet that holds multiple domes on a single backing. It aligns perfectly with the contact pads on a PCB. Each dome is placed precisely where a button or key will be. Because they’re:

- Efficient: No need to install individual domes by hand.

- Clean: Domes stay sealed under a PET film, keeping out dust and moisture.

- Customizable: Arrays can be made for any layout, including curved or flexible boards.

In manufacturing, using a dome array saves time, boosts alignment accuracy, and improves product consistency.

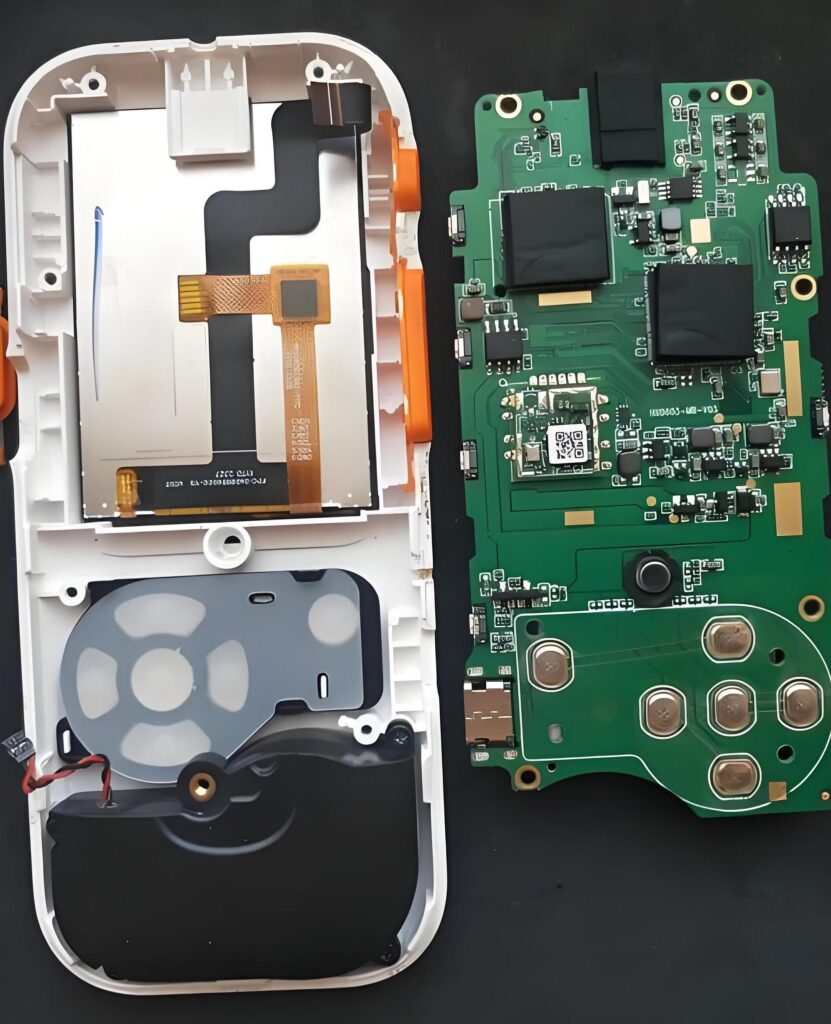

Can metal dome switches work on flexible PCBs?

Yes, metal dome switches are perfectly compatible with flexible PCBs. In fact, many devices with curved surfaces or wearable tech use this exact pairing. Metal domes can be mounted onto flex circuits using dome arrays or even laser-cut PET sheets. The combination allows for:

- Slim, bendable designs

- Lightweight structure

- Flexible button layouts

- Durable, reliable performance

From medical sensors to curved remotes, this setup is shaping the future of compact electronics. With metal domes, even flexible electronics can enjoy sharp tactile feedback.

Conclusion:

Metal dome switches for PCB offer reliable tactile feedback, long-lasting performance, and slim design—making them ideal for modern electronic applications. From dome arrays to flexible PCB use, they outperform standard buttons and membrane switches in both feel and durability.

Whether you’re working with rigid boards or flexible layouts, dome switches bring precision and performance.

Want to upgrade your PCB designs with premium tactile feedback? Contact us now at sales@metal-domes.com