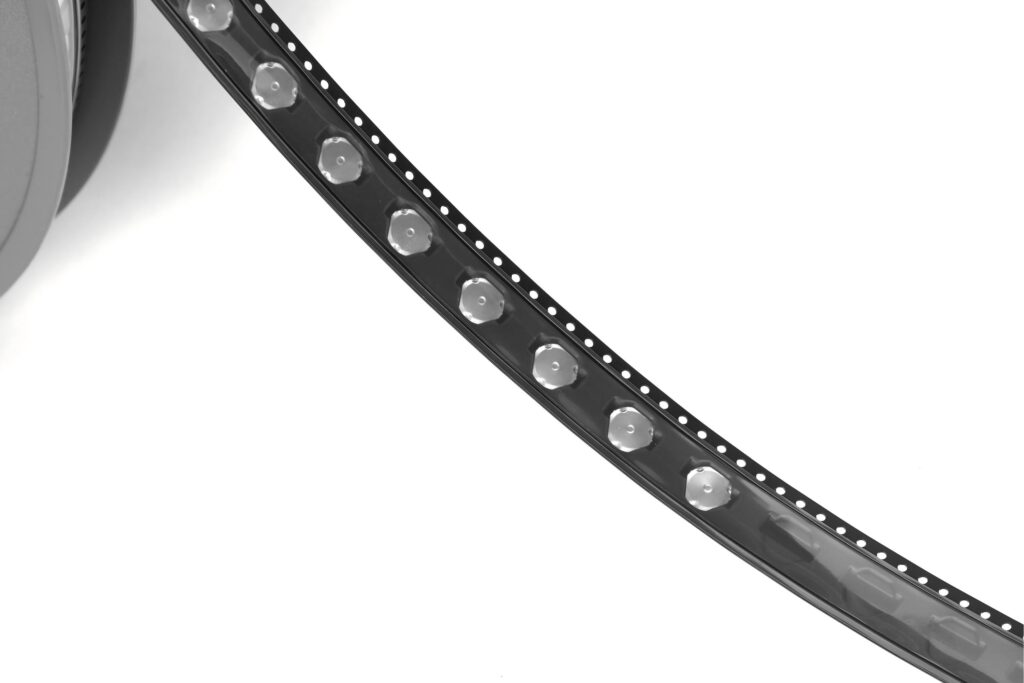

Metal dome is packaged in tape and reel because of its high protection and convenience. Tape and reel packaging arranges and fixes the dome in an orderly manner, preventing dust and moisture from damage. During automated assembly, the dome in tape and reel packaging can be directly installed to improve production efficiency and is widely used in the field of electronic manufacturing.

Why use tape and reel for metal domes?

Tape and reel is a professional packaging method designed for high-speed pick-and-place machines. For metal dome users, it offers speed, precision, and efficiency in one streamlined solution.

Each dome is sealed in an individual socket on continuous tape and rolled onto a reel. This packaging allows metal dome to be picked and placed like other SMT components, such as capacitors and resistors.

This method is ideal for domes with consistent geometry, like four-leg, triangle, and round domes. Their shapes allow smooth feeding, correct alignment, and accurate placement. With less human interaction, placement errors are greatly reduced.

By reducing the need for manual adjustment, this method improves the reliability of dome placement and raises the overall quality of production.

Is tape and reel better than bulk for snap domes?

Yes. Bulk packaging is cheaper but not suitable for automated systems. When snap domes—also known as metal domes—are packed in bulk, they shift, overlap, and can deform during shipping or handling.

Tape and reel packaging solves this issue by providing uniformity. Every dome stays fixed in position until picked. The packaging format works seamlessly with automated pick-and-place machines, eliminating manual dome alignment completely.

Bulk packaging might seem acceptable for small runs, but for large-scale SMT production, it’s inefficient. In high-volume production, tape and reel packaging is significantly superior to bulk packaging in terms of speed and reduced errors.

How does tape and reel reduce SMT errors?

SMT assembly requires consistent placement. Misaligned components result in faulty products and costly rework. Bulk-packed domes are hard to align precisely. Manual handling can lead to incorrect orientation, dome damage, or misplacement.

Tape and reel eliminates these risks. Every metal dome is packed at the same angle and position. Once loaded into the pick-and-place machine, the reel feeds domes continuously without disruption.

The reduction in manual steps directly lowers human error. Plus, the packaging protects the domes from environmental contaminants and physical wear. In a high-speed SMT line, this leads to fewer rejects and more reliable output.

Can solder domes be packed in tape and reel?

No. Metal domes, even when packed in tape and reel, are not meant for soldering. They are functional mechanical components, not electrical components for permanent soldering.

The dome is typically placed between circuit layers or under a membrane and held mechanically, not soldered. Tape and reel here is a packaging method, not a preparation for solder reflow. It’s about precision placement, not solder bonding.

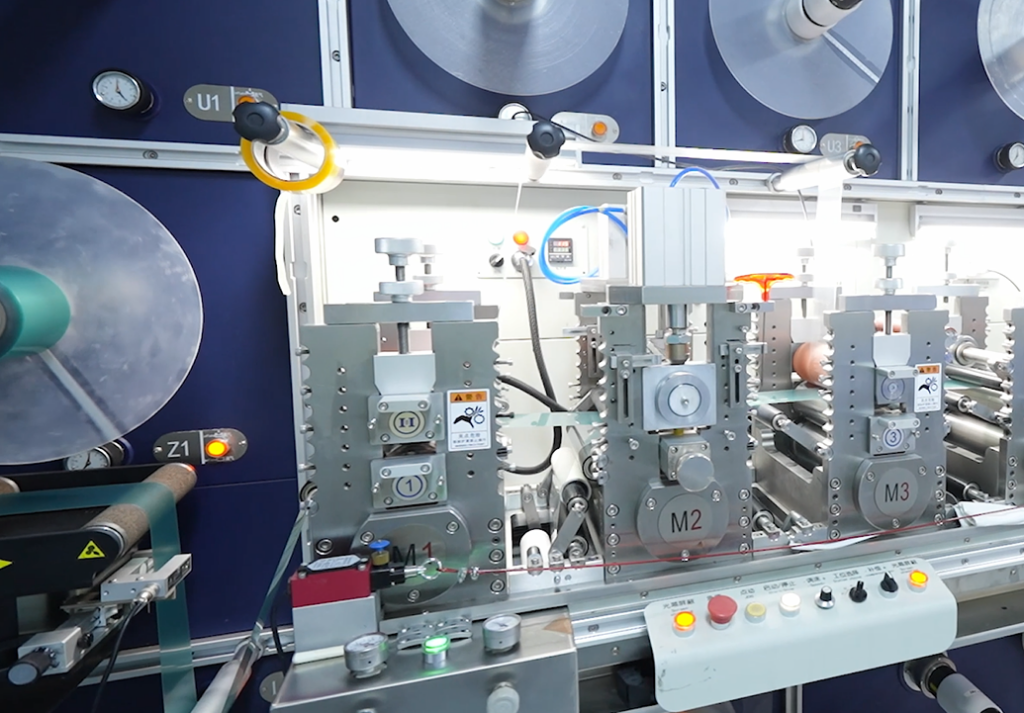

Are tape and reel metal domes suitable for automated manufacturing?

Yes. That’s exactly what they are made for. Tape and reel metal domes are compatible with all major high-speed pick-and-place systems. Whether using Panasonic, Fuji, Yamaha, or other SMT machines, the tape and reel format integrates easily into the reel feeder tray.

This allows domes to be picked just like other SMT parts. With properly calibrated machines, users can achieve speeds between 20,000 and 100,000 domes per hour, depending on machine type and dome size.

The packaging also protects domes from dust, oil, or handling damage during transport and storage. It reduces setup time and increases automation efficiency.

How does tape and reel improve dome placement speed?

In a bulk pack, domes are loose. Workers must sort, flip, and align them before placing. With trays, feeding is still manual and slow. These methods delay throughput and affect the uniformity of placement.

Tape and reel eliminates these extra steps. The dome is picked straight from the tape in perfect orientation. Machines don’t have to stop, and operators don’t have to interfere. It’s continuous, smooth, and extremely fast.

More importantly, it also minimizes dome waste. Since each pick is controlled and consistent, fewer domes are rejected due to misalignment.

Over time, this creates significant cost and time savings. For factories aiming at high output with tight delivery windows, tape and reel is the fastest route to efficient dome handling.

Are tape and reel metal domes more cost effective?

Yes—especially in large-scale operations. At first, the cost of tape and reel packaging is slightly higher than bulk or tray. But this small investment creates a big return. Consider the hidden costs in manual placement: operator time, mistakes, misalignment, and dome damage.

With tape and reel metal domes, most of those costs disappear. Machines handle placement. Errors go down. Yields go up. Production becomes more predictable. These savings add up over time, especially in environments where millions of domes are used.

Also, tape and reel minimizes setup time. You can switch reels fast and keep machines running longer. This improves efficiency and factory utilization.

In the long run, the cost per unit of a dome placed via tape and reel is often lower than a dome from bulk packaging once you factor in labor and rework.

Can tape and reel metal domes streamline the assembly process?

Yes, they streamline the entire dome integration process. No more trays or tubes to manage. No manual sorting. Just load the reel, press start, and let the machine run.

By removing manual steps, you cut down setup time and eliminate misfeeds. That leads to more consistent product quality. Engineers can spend less time debugging placement problems and more time optimizing performance.

Tape and reel metal domes also support cleaner assembly floors. There’s no loose parts or spilled domes. The process is tidy, organized, and scalable.

Conclusion:

Tape and reel is more than just packaging—it’s a smart solution for metal dome integration. It supports high-speed automation, reduces human error, and speeds up production. From snap dome switches to tactile domes, this method improves placement accuracy and cost efficiency.

If you’re looking for faster turnaround and a more professional dome assembly process, tape and reel is the way forward. For custom solutions or expert help, reach out to us at sales@metal-domes.com