When choosing a metal dome material, you need to consider the application scenario, performance requirements, and cost. SUS301 has good strength and elasticity and is suitable for dry environments; SUS304 has strong corrosion resistance and is suitable for humid environments.

How to choose the best metal dome material?

The material at the core of the dome determines how it responds to pressure, returns to shape, and endures repeated use. Will the product be used thousands of times per day? In harsh or clean environments?

Focus on these critical qualities:

- Elasticity: The ability to spring back to form quickly.

- Tensile strength: How much stress it can endure before deforming.

- Corrosion resistance: Especially important in outdoor, medical, or industrial settings.

- Forming ability: Domes need to be pressed and shaped precisely.

Why does metal dome material matter?

The material used determines:

- Actuation force: The pressure needed to trigger a response.

- Tactile feedback: That satisfying “snap” when pressed.

- Durability: How many cycles it can survive without losing function.

- Response time: How quickly it returns to position after actuation.

- Environmental endurance: How it handles humidity, sweat, or dust.

A poorly chosen material can ruin an otherwise perfect design. Meanwhile, the right one can elevate it.

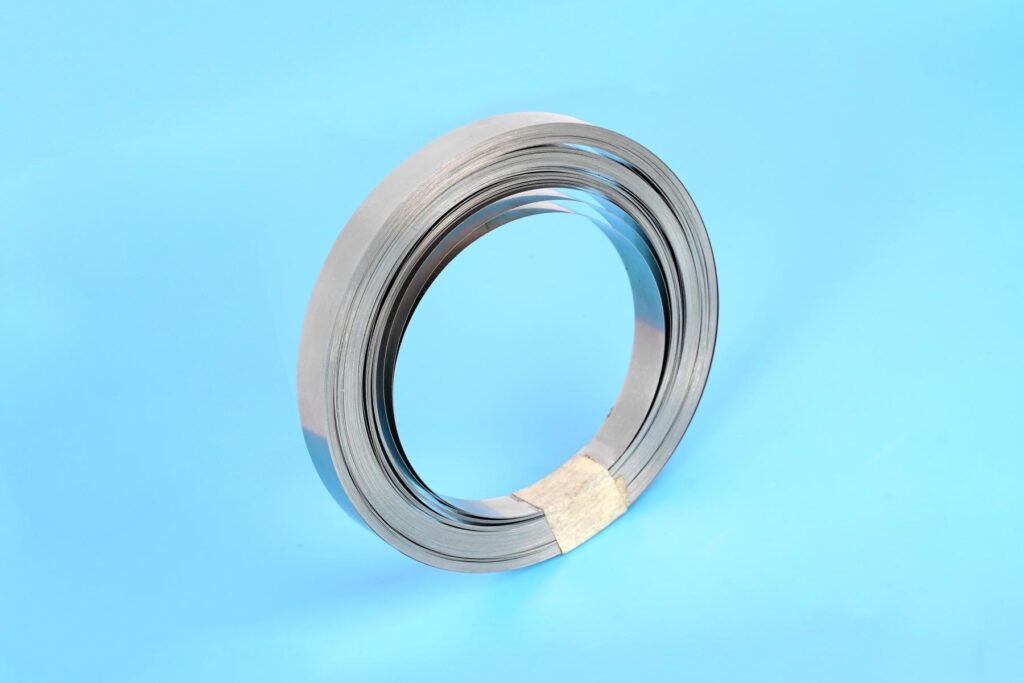

Is stainless steel the right dome choice?

Yes, in most cases, Because it offers an ideal balance of durability, cost-effectiveness, and resistance. It provides a sharp, tactile response. It resists corrosion in humid or chemically exposed environments. And it holds its form across thousands—sometimes millions—of cycles.

Depending on the application, stainless steel domes are available in varying grades and thicknesses. For example:

- SUS301: Known for high elasticity and fatigue resistance.

- SUS304: Offers better corrosion resistance, great for medical or marine equipment.

Stainless steel is also easy to plate with gold or nickel, which improves conductivity and oxidation resistance in sensitive environments.

What affects dome switch feel—material or shape?

Both play vital roles. Shape determines the feel—like force required or tactile strength—but without the right material, even a perfect shape won’t perform well.

Material affects:

- The crispness of the tactile response

- The dome’s ability to reset quickly

- How it performs after thousands of presses

Shape affects:

- How much force is needed to actuate the dome

- The click sound and feel

- The contact area

So, focus first on the metal type. Then fine-tune shape and size based on your desired tactile experience.

How does material impact dome lifespan?

A dome’s lifespan is typically measured in actuation cycles—how many times it can be pressed before losing its form or failing. Metal dome material plays a critical role here.

High-quality stainless steel domes, like those from BEST Technology, can reach over 1 million cycles without performance loss. Some specialty domes even exceed 5 million cycles, depending on the environment and design.

Lesser materials—like aluminum or low-grade steel—may feel fine at first. But they fatigue faster. They warp, lose their tactile snap, or fail entirely under pressure or temperature shifts.

If your product is expected to perform reliably over time, don’t cut corners on the dome material. It’s not just a part—it’s the core of the user experience.

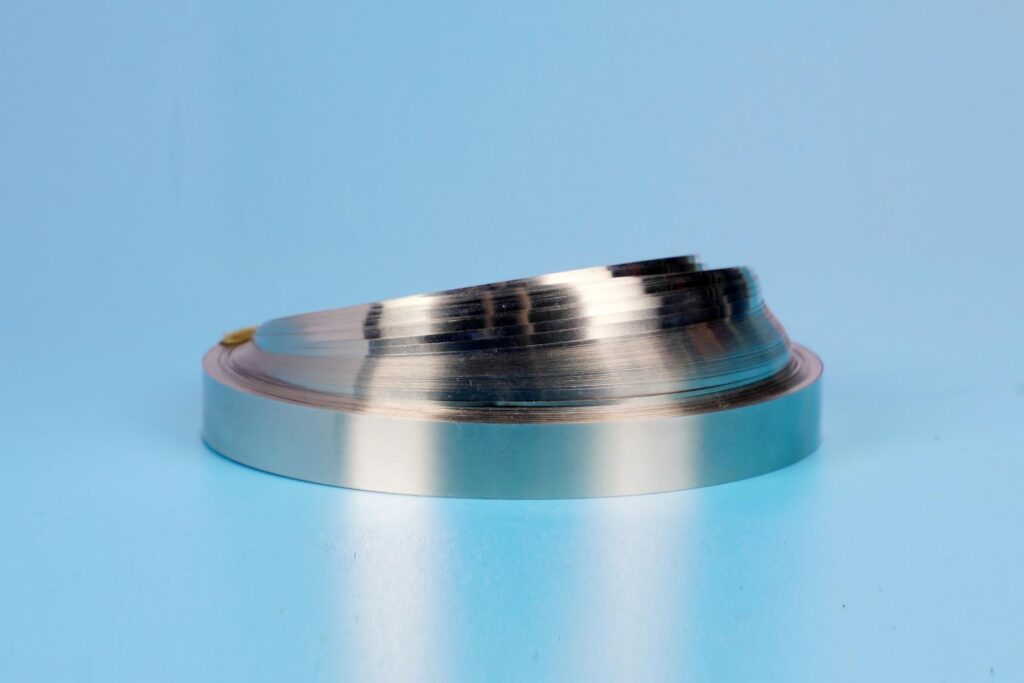

Is thickness or material more important?

The answer is—they both matter, but for different reasons. Material determines the mechanical properties. It affects fatigue life, resilience, and corrosion resistance.

Thickness fine-tunes the tactile force and feedback. A thicker dome might feel stronger and last longer—but it also requires more force to actuate. Too thin? It may respond quickly but wear out faster.

In BEST Technology, engineers help match the right thickness and metal grade for your specific use case.

How does metal hardness affect dome switches?

Hardness refers to how resistant a material is to permanent shape change. Harder domes feel snappier and resist deformation—but might crack or wear contact layers faster. Softer domes offer smoother tactile feedback—but risk losing form or tactile snap sooner.

Stainless steel again offers a balanced hardness range, which is why it dominates the dome market.

BEST Technology further tests hardness to fine-tune performance. Domes are crafted to offer high fatigue resistance while maintaining the desired tactile feedback, even under extreme use.

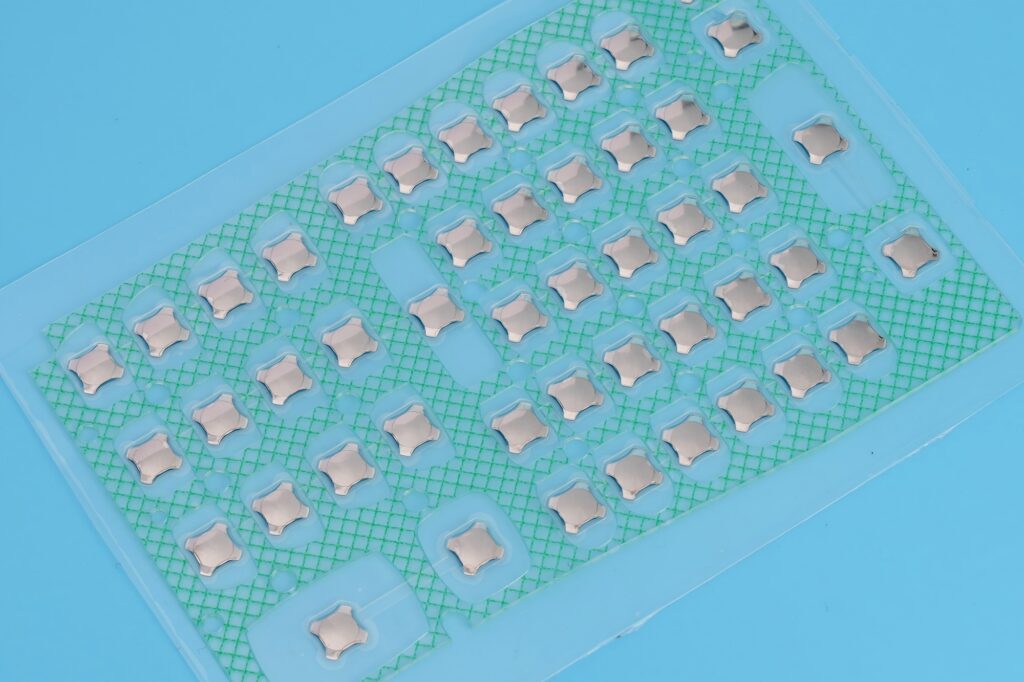

Why choose BEST Technology’s metal dome array?

Because performance, speed, and support matter. BEST Technology doesn’t just sell domes. They deliver complete peace of mind.

Here’s what sets them apart:

- Precision Engineering: Contact accuracy up to ±0.05mm for ultra-consistent array layouts.

- Extended Lifespan: Domes designed to exceed 1 million cycles without degradation.

- Fast Turnaround: Industry-leading 2-3 day delivery time (vs. 7-15 days elsewhere).

- Cost Efficiency: Save up to 37% on labor with arrays vs. bulk domes; up to 4x mounting efficiency.

- Flexible Orders: Support for small batches and free first samples.

- Complete Documentation: Full technical parameter package, including ROHS/REACH certificates.

- Technical Support: Get expert feedback within 48 hours of your sample reaching them.

Conclusion:

Choosing the right metal dome material is a decision that impacts every touchpoint of your product. Stainless steel continues to lead the market due to its unmatched balance of strength, flexibility, and resistance.

And when sourced from a trusted manufacturer like BEST Technology, you don’t just get quality materials—you get real engineering support, fast delivery, and flexible solutions. Contact us today at sales@metal-domes.com