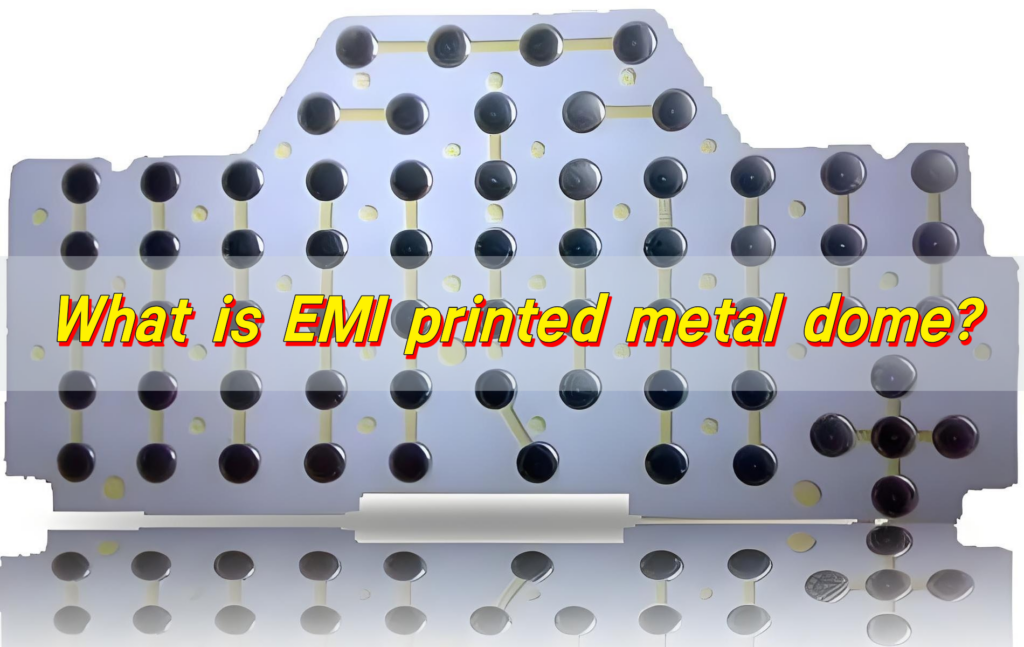

EMI printed metal dome is a conductive film made by printing silver paste or silver carbon oil on the metal dome conductive film. This design can effectively prevent electrostatic damage and is suitable for mobile phones, walkie-talkies and other devices that need to be protected from radiation. It can enhance electromagnetic compatibility, guide interference current to the ground wire, and prevent electrostatic discharge.

What is EMI printed metal dome array?

To begin with, EMI stands for Electromagnetic Interference. This interference can come from other devices, circuits, or external sources. It causes problems—like screen glitches, signal drops, or even hardware failure. That’s where the EMI printed metal dome comes in.

Metal dome is a small, thin piece of stainless steel that works as a tactile switch. When pressed, it gives a satisfying click and completes a circuit. But when EMI shielding is needed, an extra layer is printed or coated onto the dome. This layer can block or absorb unwanted electromagnetic signals.

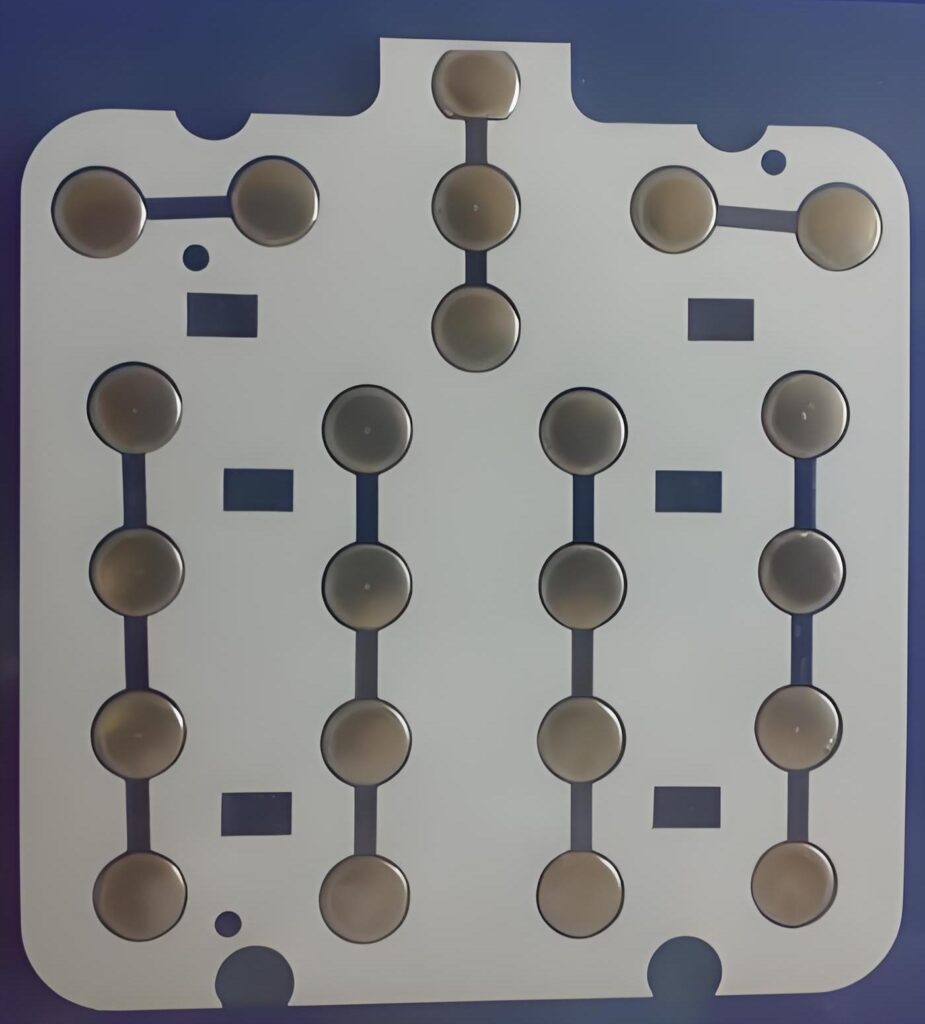

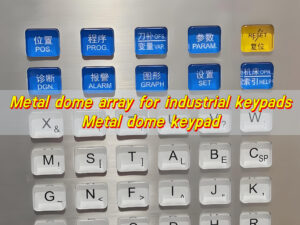

When grouped in arrays, these domes form a printed dome array. Think of it as a flexible switch sheet that sits under a keypad. Each dome in the array works as an individual button, but also serves a double role—it prevents EMI and ensures reliable signal flow.

This technology is widely used in critical environments like aerospace, defense systems, medical instruments, and high-end industrial controls.

How is an EMI dome made?

Creating an EMI printed metal dome takes skill, precision, and advanced technology.

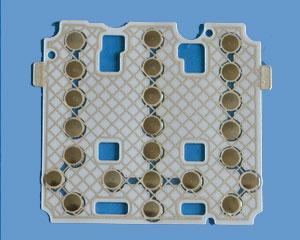

The process starts with a high-quality stainless steel sheet. Using laser cutting or stamping, engineers shape it into tiny domes. These domes are then coated or printed with conductive ink, silver epoxy, or nickel-based layers. These materials form a shield that reflects or absorbs electromagnetic waves.

Next, these printed domes are tested for resistance, actuation force, click life, and shielding strength. Only those that meet exact specifications are passed on to customers.

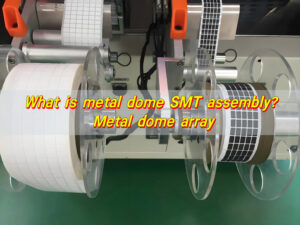

Some domes are built into adhesive-backed arrays. These arrays can be applied directly onto PCBs or control panels for easy integration.

What makes the process even more effective is customization. Manufacturers like Best Technology offer various dome sizes, force levels, and print options to meet different device requirements.

What materials are used for EMI printed metal domes?

Material choice is everything in EMI applications. Here’s what you’ll typically find in a reliable EMI dome:

- Stainless Steel (SUS304 or SUS301): This is the base. It’s strong, corrosion-resistant, and offers good spring properties.

- Conductive Inks or Coatings: These can include silver epoxy, carbon ink, or nickel-based solutions. They act as the EMI shield.

- Adhesive Substrate: For dome arrays, the domes are mounted on polyester films with pressure-sensitive adhesives.

All materials are carefully chosen to balance conductivity, durability, and flexibility. The dome must return to its original shape after being pressed—every time. It must also maintain its EMI shielding properties, even after thousands of presses.

How does EMI shielding work?

Electronic devices generate signals. Sometimes, these signals create electromagnetic waves. When these waves are not controlled, they can interfere with other parts of the circuit—or even other devices nearby. That’s what we call EMI.

An EMI printed dome works by forming a barrier. It either reflects the unwanted signals away or absorbs them before they can spread.

This shielding can protect sensitive components, prevent communication errors, and enhance signal clarity.

Even a small metal dome, when properly printed with EMI materials, can greatly reduce interference. It forms a part of the complete shielding system inside a device.

What is the function of EMI printed metal dome?

Here’s what it does:

- Acts as a Switch: When pressed, it completes an electrical path. This sends a signal to the device’s control board.

- Provides Tactile Feedback: The user feels a click, which confirms the input.

- Shields Against EMI: The printed coating blocks interference from reaching critical circuits.

- Improves Reliability: It reduces false triggers and enhances signal accuracy.

- Lasts Longer: Because of its design and materials, the dome maintains performance over millions of cycles.

Where are EMI metal domes used?

They are essential in:

- Medical Devices: These require absolute accuracy and zero interference.

- Aerospace Systems: Where reliability and communication clarity are non-negotiable.

- Military Equipment: EMI protection is critical for secure and stable operations.

- Industrial Control Panels: To avoid data loss or machinery errors.

- Automotive Interfaces: For cleaner signal control in dashboard units and onboard systems.

- Smart Home Devices: Where Wi-Fi, Bluetooth, and RF signals can easily interfere with each other.

Anywhere EMI can disrupt function, their role is vital yet invisible.

What are the advantages of EMI printed metal domes?

- 1. Dual Functionality: One part gives both tactile feedback and EMI protection.

- 2. Customization: Dome size, actuation force, coating thickness, and array layout can all be tailored.

- 3. Long Life Span: Many domes last up to 1 million clicks or more without losing performance.

- 4. Compact Design: Fits into slim devices and complex layouts.

- 5. Cost-Effective EMI Solution: Instead of adding separate shielding layers, the dome itself provides protection.

- 6. Fast Response: The tactile design ensures minimal delay in command execution.

- 7. Simple Integration: Arrays with adhesive backing are easy to install.

All these advantages add up to superior device performance and long-term reliability.

Is BEST Technology’s EMI dome reliable?

Best Technology has over 18 years of experience in dome manufacturing. Their EMI printed domes are crafted with precision and care in their advanced facilities in China and Vietnam. Every dome is tested for force, rebound, shielding strength, and click life.

Clients across medical, automotive, and industrial fields trust Best Technology for one reason—performance you can count on.

Here’s what sets them apart:

- ISO-certified production standards

- Custom engineering support

- Strict quality control

- Global delivery options

- Responsive customer service

Conclusion:

The EMI printed metal dome is more than just a switch. It combines tactile precision with EMI defense. It’s flexible, durable, and dependable. Whether in medical monitors or military-grade panels, these domes ensure every press counts—and every signal stays clean.

And with Best Technology, you get the best in class—engineered to last, customized to fit, and trusted by professionals worldwide. For more information, or to request a sample, reach out to us at sales@metal-domes.com