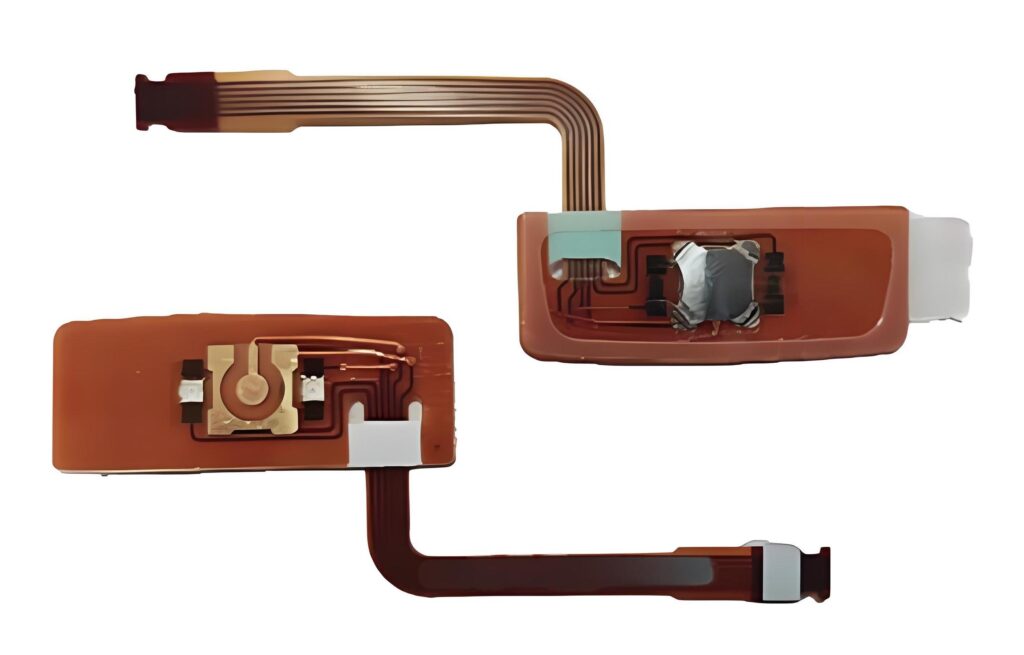

Through hole technology domes are metal domes mounted on circuit boards using through-hole technology (THT). They pass through the through-holes of the circuit board through pins and are soldered on the other side to form a stable electrical connection. This dome provides good conductivity and mechanical stability and is widely used in electronic devices that require high reliability and durability.

What is the through-hole technology?

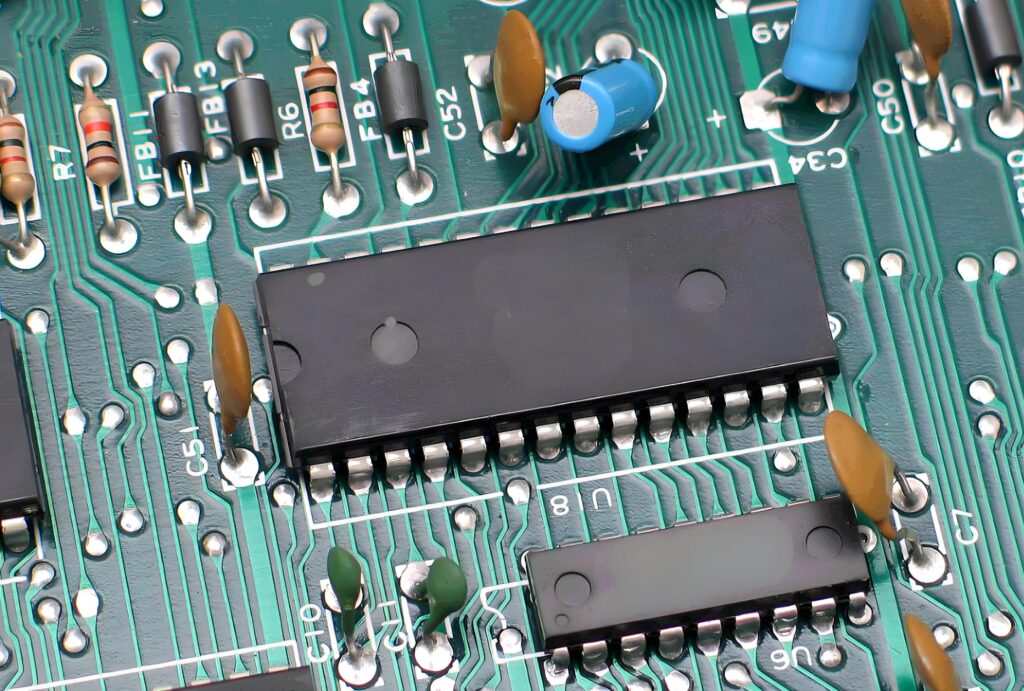

Through-hole technology, often abbreviated as THT, refers to the method of mounting electronic components by inserting their leads into pre-drilled holes on a printed circuit board (PCB). Once placed, the leads are soldered to pads on the opposite side. This creates a strong mechanical bond.

Unlike newer surface mount technologies (SMT), THT has been around for decades. This method ensures robust connections. When vibrations, shocks, or extreme conditions are a concern, THT is the go-to choice.

That’s why through hole technology domes have earned their place in tough environments. These domes, made from high-quality stainless steel, are precise, tactile, and reliable.

What is the difference between through-hole technology and surface mount technology?

Surface mount technology involves placing components directly on the surface of the PCB. It’s fast and efficient, perfect for high-volume manufacturing.

Through-hole mounting, on the other hand, offers superior durability. When it comes to metal dome switches that require precision tactile feedback, THT delivers. The leads go through the board, anchoring the metal dome in place. This makes snap dome switches ideal for devices that undergo frequent pressing, intense use, or face harsh environments.

While SMT dominates in mobile and compact electronics, THT shines where reliability cannot be compromised. Think aerospace, automotive, industrial machinery, and medical devices.

What are the advantages of through-hole technology?

- Unmatched Mechanical Strength: Components installed using THT are less likely to shift or detach. The physical bond is incredibly secure.

- Reliable Tactile Feedback: Every press of a metal dome switch feels intentional. The tactile response is clean and satisfying.

- Excellent Heat Resistance: Because the domes are secured through the board, they can handle higher heat without warping or failure.

- Long-Term Durability: THT domes offer years of consistent performance. They don’t wear down easily.

- Easy Manual Assembly and Repair: SMT is great for automation. But THT components are easier to test and replace.

What is the purpose of a through-hole?

A through-hole is more than just a tiny opening on a PCB. It’s a gateway for connectivity and strength. It’s where the magic happens. When the lead of a metal dome or other component enters this hole, it connects two sides of the board.

It also helps stabilize the component. For snap dome switches, the through-hole anchors the dome, ensuring that it won’t move or shift over time. The electrical signal passes through with minimal resistance, providing a fast and reliable response.

What are the different types of through-hole?

There are generally two types of through-holes used in electronics manufacturing:

- Plated Through-Hole (PTH): These holes have a conductive plating inside. They are used for both mechanical mounting and electrical connectivity. Most metal dome switches use PTH to ensure both strength and function.

Non-Plated Through-Hole (NPTH): These are not electrically conductive and are used mainly for mounting or alignment. While not as common for switches, they may appear in hybrid designs.

What is the installation process of through hole technology domes?

Installing through hole technology domes involves precision and care. Here’s how it typically works:

- Step 1: PCB Preparation

The circuit board is fabricated with pre-drilled holes according to the design. These are precisely placed for each dome.

- Step 2: Dome Insertion

Each metal dome, often mounted on a flexible array or in a housing, has its leads inserted into the designated through-holes.

- Step 3: Soldering

The leads are soldered on the underside of the PCB. This secures the dome both electrically and physically.

- Step 4: Testing

Every dome is tested for responsiveness and continuity. This ensures that each snap dome switch works perfectly before assembly.

- Step 5: Final Assembly

The PCB is integrated into the larger device. Whether it’s a medical keypad or an industrial control panel, the dome is ready for action.

Through-hole installation might take a bit more time than surface mounting. But the payoff is long-term reliability.

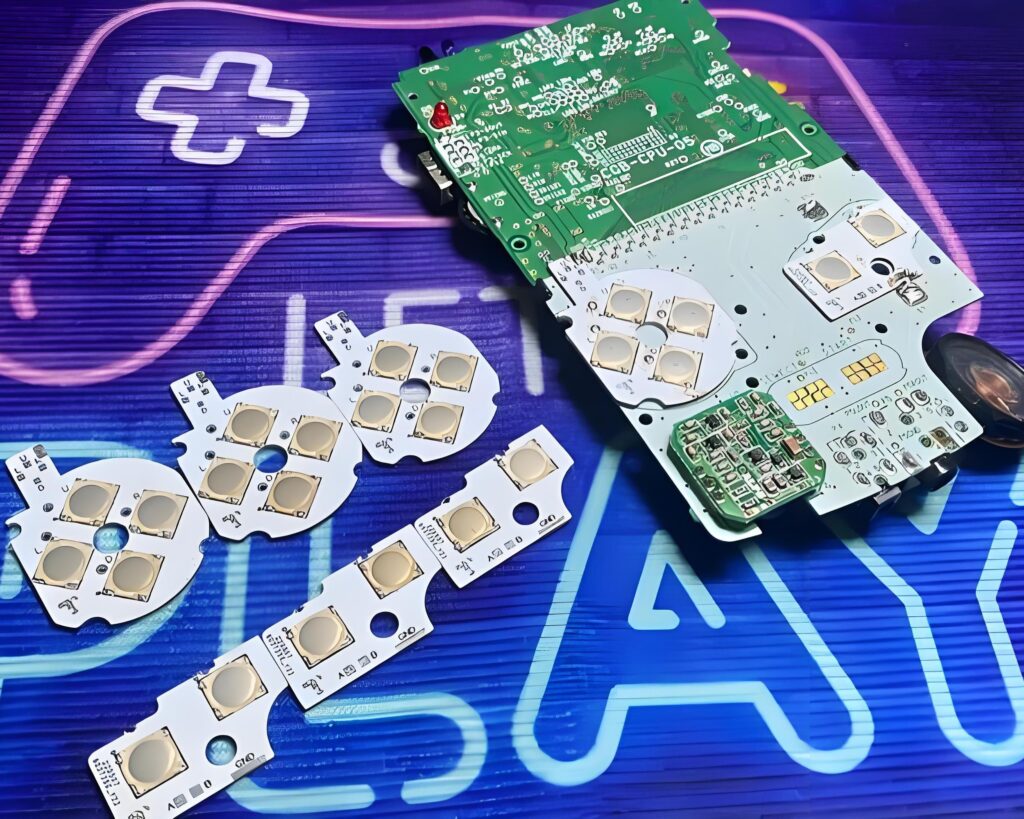

What applications commonly use through hole technology domes?

- Medical Devices: Metal dome switches offer both tactile clarity and reliability in diagnostic and treatment equipment.

- Aerospace Controls: In high-altitude environments, where stability matters, through-hole mounted domes maintain consistent function.

- Automotive Interfaces: Car dome light switches and dashboard controls need rugged performance. Through hole technology delivers it.

- Industrial Equipment: Machinery control panels use these domes for long-term use. Each press gives solid feedback—even after thousands of cycles.

In each of these applications, the benefits of a snap dome switch mounted through-hole are clear: durability, reliability, and precise response.

How do through hole technology domes impact pcb design?

PCB design changes dramatically when you choose through-hole domes.

- Hole Placement and Size: Precision is essential. Each hole must match the lead spacing and dome size perfectly.

- Component Spacing: Through-hole domes may require more board real estate than SMT versions. Designers need to plan carefully.

- Signal Routing: Traces must align with the dome’s function. Designers route signals to the dome while keeping interference low.

- Layer Management: Multilayer boards need clear via structures and signal paths. The dome’s position affects all layers.

- Testing Access: Since these domes are often tested post-installation, test pads or interfaces need to be included.

Choosing through hole technology doesn’t limit your creativity—it expands your options. When reliability is the priority, the design must support that from the ground up. Best Technology metal dome solutions are crafted with that principle in mind.

Conclusion:

Through hole technology domes bring durability, tactile precision, and electrical performance together. Whether it’s a snap dome switch in a medical device or a car dome light switch, their role is irreplaceable.

If you’re seeking high-performance metal dome switches that are built to last, look no further. Reach out to our team at sales@metal-domes.com