Stainless steel metal domes are highly favored for their excellent corrosion resistance and mechanical properties. They can remain stable in various harsh environments and are not easy to rust. At the same time, they have high strength and good elasticity, ensuring reliable performance in long-term use. These characteristics make them the first choice in the electronics, automotive and industrial fields, and are widely used in membrane switches, touch switches and mechanical structural parts.

What is a stainless steel metal dome?

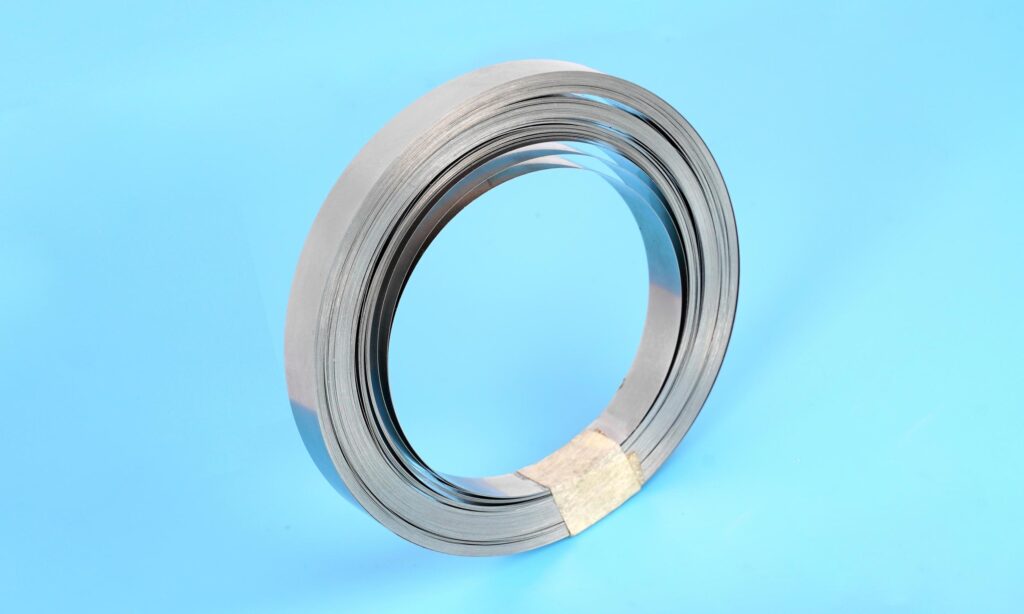

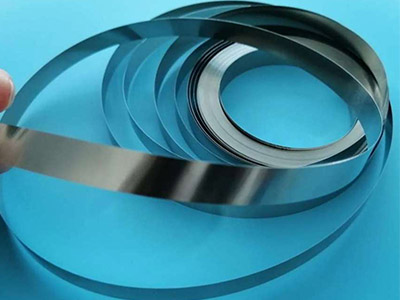

Stainless steel metal dome is a thin, precisely formed metal switch element made from stainless steel. It’s the heart of many tactile switches, providing that crisp click-feel and signal reliability users rely on. These domes are often used under membrane keypads, printed circuit boards, or flexible circuits.

When you press on the dome, it collapses and creates a circuit by making contact between conductive layers. When you release it, it springs back into shape. This simple action powers countless operations—from starting a car to triggering a piece of medical equipment.

The material and shape of the dome are what determine how well it performs, how long it lasts, and how good it feels. That’s where stainless steel makes a big impact.

What metal types are best for dome switches?

There are several metal types used for switch domes, including copper alloys, nickel-plated brass, beryllium copper, and of course, stainless steel.

For example, beryllium copper offers flexibility but lacks the toughness stainless steel delivers. Copper can corrode. Nickel-plated brass can lose its coating over time. Some materials might feel nice initially but degrade fast under repeated use. That’s where sheet and metal selection plays a critical role.

Stainless steel, on the other hand, offers a well-rounded blend of strength, resilience, and corrosion resistance. It can be shaped into domes with exacting force curves and bounce-back response. These are vital for high-use applications where failure isn’t an option.

Why choose stainless steel for metal domes?

- Exceptional durability – Stainless steel is known as one of the strongest metals in its class. It resists fatigue and cracking, even after millions of actuations.

- Corrosion resistance – One of stainless steel’s biggest advantages is its natural resistance to rust. No coatings are needed to protect it, unlike some other metals.

- Consistent tactile response – Stainless domes bounce back fast, offering a crisp, clean feel with every press.

- Cost-effective performance – Though not the cheapest material, stainless steel offers more value per click over time.

- Thin but tough – Even at very thin gauges, stainless steel domes maintain strength and flexibility.

So if you’re choosing a dome switch for high-reliability products, stainless metal is your best bet.

What are the types of steel used in domes?

The most common grades used for domes are 301 and 304 stainless steel. Both are high-performance options, but they serve slightly different purposes.

- 301 Stainless Steel: High yield strength and excellent fatigue resistance. It’s great for applications requiring frequent actuation and sharp tactile response.

- 304 Stainless Steel: Known for its corrosion resistance. Often used where domes are exposed to moisture, chemicals, or high temperatures.

These steel sheets are precision-formed into domes using a stamping process. The forming process enhances their spring properties and gives them the right force curve for specific applications.

What’s the difference between steel and stainless steel?

It’s easy to confuse regular steel and stainless steel. Both are strong. Both are used in manufacturing.

Steel is primarily iron with a bit of carbon. It’s strong but prone to rust unless coated or treated. Over time, moisture, air, and wear can eat away at its surface.

Stainless steel, by contrast, includes chromium, which forms a protective layer on the surface. This makes it resistant to corrosion, staining, and rust. It holds up better in environments where metal fatigue or exposure is an issue.

In the world of dome switches, that means longer lifespan, better performance, and reduced failure rates.

How does metal sheet affect dome performance?

The choice of metal sheet metal plays a major role in how a dome performs. If it’s not the right kind or not processed well, the final dome won’t work as expected.

Key performance areas affected by the sheet include:

- Tactile force: The thickness and alloy determine how much pressure is needed to activate the dome.

- Bounce-back time: High-quality stainless steel domes return to shape faster, giving a snappier response.

- Durability: Inferior metal types wear out quicker, especially under heavy use.

- Consistency: Poor-quality sheet metal metal can result in uneven domes and inconsistent feel across keypads.

This is why selecting the right sheet stainless matters.

What is a stainless steel metal dome used for?

You can find stainless steel metal domes in a huge variety of industries. Some common applications include:

- Medical Devices – For precise input and dependable feedback.

- Industrial Controls – For rugged machines used in extreme environments.

- Automotive Electronics – Used in dashboards, remote controls, and gear selectors.

- Consumer Electronics – From handheld devices to appliances.

- Military Equipment – Where long-term reliability is non-negotiable.

These domes are built into membrane switches, rubber keypads, or even directly on online metal circuits. Because of their versatility, they work well in both simple and complex systems.

Why choose Best technology custom stainless steel metal dome?

When it comes to custom dome solutions, Best Technology stands out. With years of experience, cutting-edge manufacturing, and a deep understanding of metal performance, we deliver unmatched quality.

Our advantages are:

- Tailored force curves – We design domes with the exact feel your application needs.

- Top-tier raw materials – We use only certified steel stainless steel and proven forming methods.

- Rigorous testing – Every dome goes through mechanical and environmental tests before it reaches your line.

- Fast lead times – With production facilities in both China and Vietnam, we deliver faster.

- Expert support – Our team helps you from design to production.

If your product depends on flawless tactile performance, choosing the right dome supplier is just as critical as choosing the right material. From metal sheets to final testing, we’re hands-on at every step.

Conclusion:

Stainless steel metal domes are more than just parts. They’re the heartbeat of reliable electronic interfaces. Whether you’re designing for safety, performance, or longevity, choosing the right metal is everything.

With stainless steel, you’re getting one of the strongest metals with proven durability, consistent response, and a clean, corrosion-free life. And when paired with expert design and manufacturing, the results speak for themselves.

For more information or to start your custom dome design, reach out to us at sales@metal-domes.com