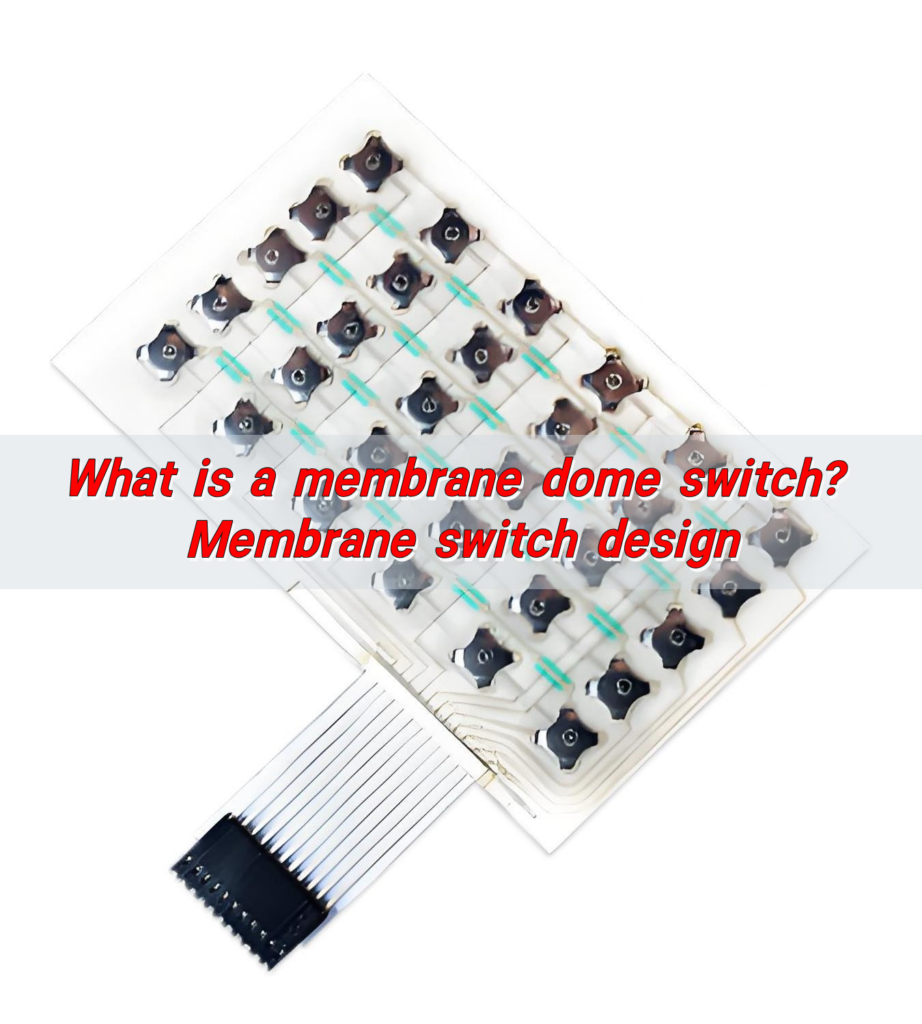

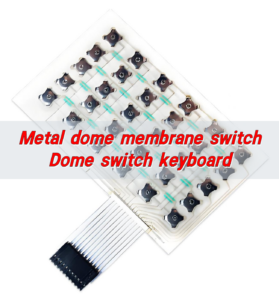

The membrane dome switch is a membrane switch that contains a thin metal dome that contacts the circuit when pressed. The key to its design lies in the multi-layer structure, including the panel, conductive layer, insulating layer and circuit layer. The panel is dustproof and waterproof and marks the button position, the conductive layer transmits electrical signals, the insulating layer prevents short circuits, and the circuit layer realizes the function.

What are membrane switches?

Membrane switch is a type of electrical switch made from layers of flexible, thin materials. These layers form a circuit, which is activated by the pressing of a button or key on the membrane’s surface. In the world of switches, membrane switches are a go-to option due to their versatility, ease of use, and cost-effectiveness.

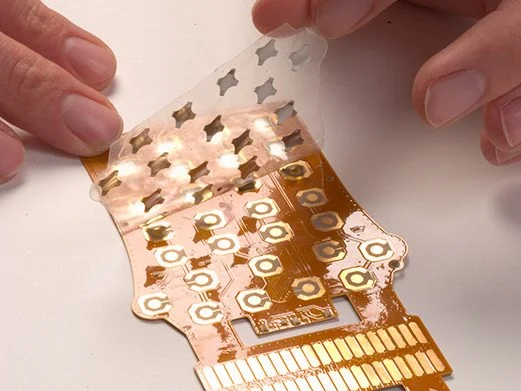

The design of a membrane switch typically includes three basic layers: the top layer, which is often made of polyester or polycarbonate, the middle conductive layer, and the bottom layer, which is usually a non-conductive surface. When a user presses down on the membrane switch, the top layer compresses, and the conductive layer makes contact with the bottom layer, completing the circuit and sending a signal to the device.

Membrane switches are commonly used in many applications due to their flexibility, durability, and ability to be customized for specific needs.

How do membrane switches work?

Membrane switches work through a simple yet effective mechanism. When pressure is applied to the surface of the membrane, it causes the conductive layers to close the circuit. This activates the underlying device, triggering an action such as turning on a light, adjusting volume, or registering a key press.

What sets membrane dome switches apart from other types of membrane switches is the addition of a dome structure—usually made of metal. This dome is placed beneath the surface of the switch and, when pressed, provides a tactile “snap” feeling. This snap feedback is especially valuable in devices where user interaction needs to be clearly communicated, such as in medical equipment, industrial controls, and consumer electronics.

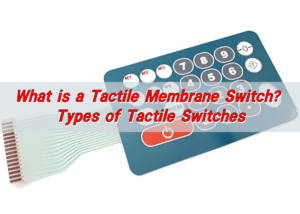

What is a tactile dome switch?

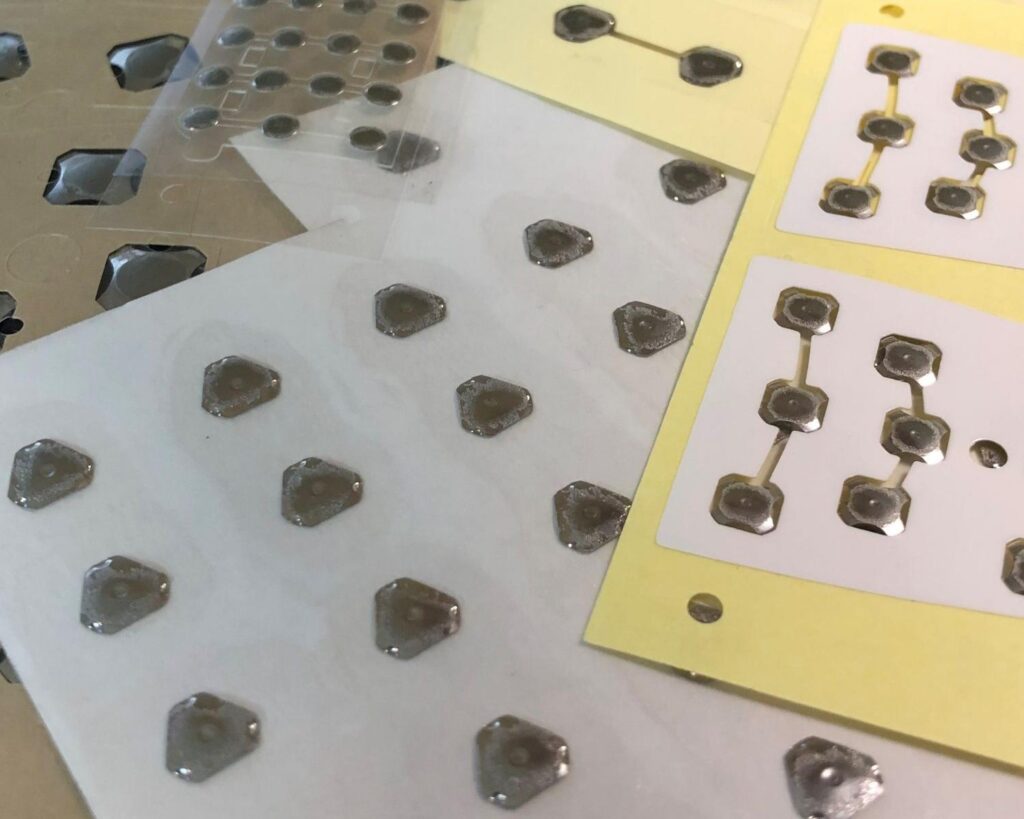

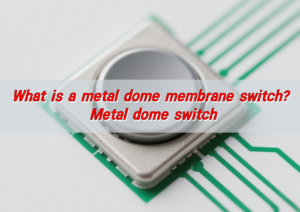

Tactile dome switch, often referred to as a metal dome switch or snap dome switch, is a specific type of membrane switch. Unlike regular membrane switches, which may only provide visual feedback when activated, a tactile dome switch provides physical feedback. This feedback is due to the metal dome underneath the switch’s surface.

The metal dome is designed to flex when pressed. Once the dome reaches a certain level of compression, it “snaps” into place, sending an electrical signal to the device. This snap action ensures that users get immediate feedback that the switch has been activated, which is particularly important in high-stakes environments like medical devices or machinery control.

Tactile dome switches can be designed to give varying levels of feedback, ranging from a subtle click to a more pronounced snap, depending on the requirements of the specific application.

What is the difference between membrane and dome switch?

Though membrane switches and dome switches are often mentioned together, they are not the same. The primary difference lies in their structure and the feedback they offer.

Membrane switch, as mentioned earlier, is made of multiple layers of flexible material. It works by completing a circuit when the top layer is pressed down. This type of switch is highly reliable and simple to manufacture, but it lacks the physical feedback that many users find useful.

In contrast, a dome switch, or membrane dome switch, incorporates a metal dome underneath the surface of the switch. This dome creates a tactile feedback when pressed, offering users a distinct sensation to confirm that the switch has been activated. The dome switch typically offers greater durability and a more pleasant user experience than a traditional membrane switch.

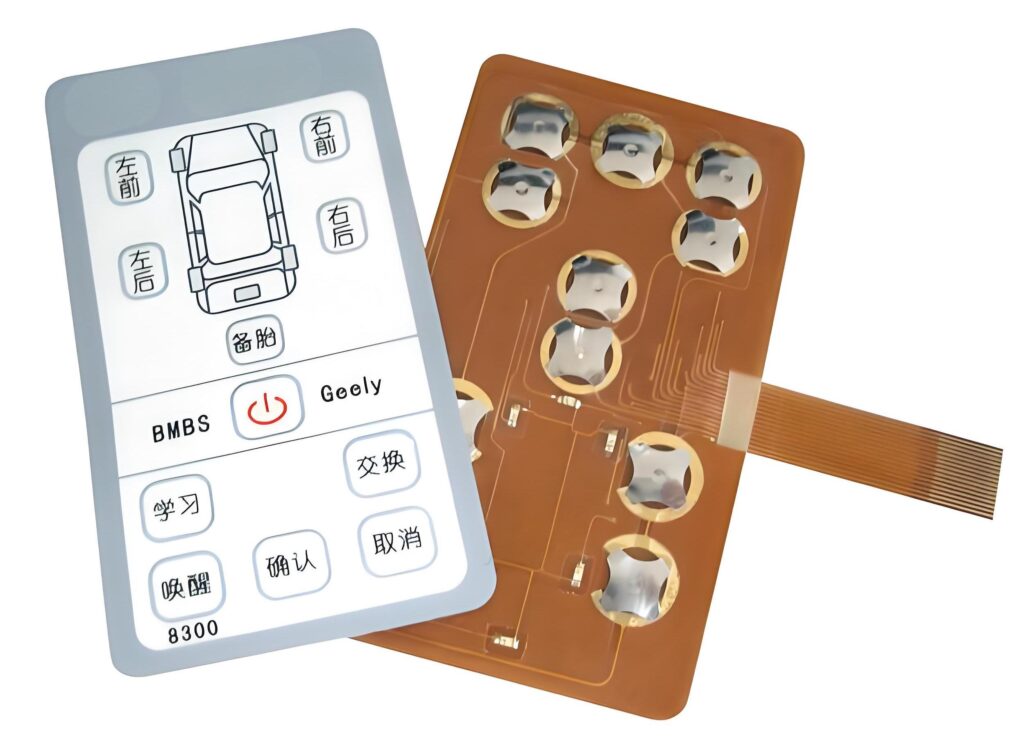

Another important distinction is in the design. Membrane switches are often thin, lightweight, and capable of being customized to fit a variety of applications. Dome switches, on the other hand, add a layer of complexity and a more robust structure, making them suitable for high-performance applications.

Why choose metal dome membrane switch?

The metal dome membrane switch offers a unique combination of benefits that can be critical in many applications.

- Enhanced User Feedback: The tactile “snap” provided by the metal dome is a key feature that makes these switches ideal for applications where user feedback is important.

- Durability: Metal dome switches are highly durable, offering long-lasting performance even in harsh environments. The metal dome can withstand thousands (or even millions) of presses without losing functionality.

- Customization: Metal dome membrane switches can be customized to fit the needs of any specific application.

- Cost-Effectiveness: Compared to more complex switches, metal dome membrane switches offer a cost-effective solution without sacrificing quality.

What does a membrane switch do?

Membrane switch serves as the interface between a user and a device. It allows users to send signals to the device by pressing buttons or keys. This functionality is fundamental in countless applications, from household appliances like microwaves to industrial machinery and medical equipment.

In simple terms, the membrane switch translates user input into action by completing a circuit when pressed. It can be used to control everything from the temperature settings on a machine to adjusting the volume on a speaker. The inclusion of a metal dome under the surface of the switch elevates the user experience by providing tactile feedback.

What is the advantage of membrane switch?

Membrane switches offer several advantages that make them a preferred option in various industries:

- Simplicity: The design of membrane switches is straightforward, making them easy to manufacture and implement. There are fewer moving parts compared to mechanical switches, which means there is less risk of failure.

- Sealed and Resistant: Membrane switches are sealed, making them resistant to dust, dirt, and moisture. This makes them ideal for use in environments where cleanliness and durability are critical.

- Compact and Lightweight: Membrane switches are thin and lightweight, which is advantageous for products where space is limited, such as handheld devices and compact electronics.

- Easy Customization: Membrane switches can be easily customized to fit different applications. The design can include various colors, button layouts, and labels, offering flexibility without adding complexity or cost.

- Affordability: Membrane switches are generally more affordable compared to mechanical switches, making them a cost-effective solution for many projects.

Where are membrane switches used?

Membrane switches are found in a wide range of applications across various industries. Some of the most common areas where membrane switches are used include:

- Consumer Electronics: Keypads and control panels on products like microwaves, coffee machines, and TVs often use membrane switches.

- Industrial Controls: Membrane switches are frequently used in control panels for machinery, where durability and resistance to harsh conditions are essential.

- Medical Devices: Devices such as diagnostic equipment, infusion pumps, and blood pressure monitors often rely on membrane switches for user input.

- Automotive: Control systems in cars, including climate control systems and dashboard buttons, use membrane switches for their sleek design and easy functionality.

- Military and Aerospace: Membrane switches are also used in high-performance environments where reliability and resistance to wear are crucial.

Conclusion:

In conclusion, membrane dome switches are an integral part of modern technology, providing reliable and efficient input mechanisms across numerous industries. Whether you’re designing a medical device, a consumer product, or an industrial machine.

For more information or to discuss your specific needs, feel free to reach out to us at sales@metal-domes.com