Türkiye’s top 10 dome array manufacturers bring together the region’s leading dome array R&D and manufacturing capabilities, covering a full range of services including customized design, precision manufacturing, and rapid prototyping. By deeply analyzing the core competitiveness of Türkiye’s top 10 dome array manufacturers, we provide clients with reliable and cost-effective cooperation options, precisely addressing industry pain points.

Are you facing any of the following problems?

- Prototyping cycles are too long, failing to meet urgent project launch needs.

- Design solutions do not match actual application scenarios, leading to high costs for later modifications.

- Product precision is substandard, affecting the stability of terminal equipment.

- Low yield rates in mass production result in high production costs.

- Slow response to customized needs makes it difficult to adapt to individual project requirements.

- Insufficient after-sales technical support and untimely troubleshooting affect production schedules.

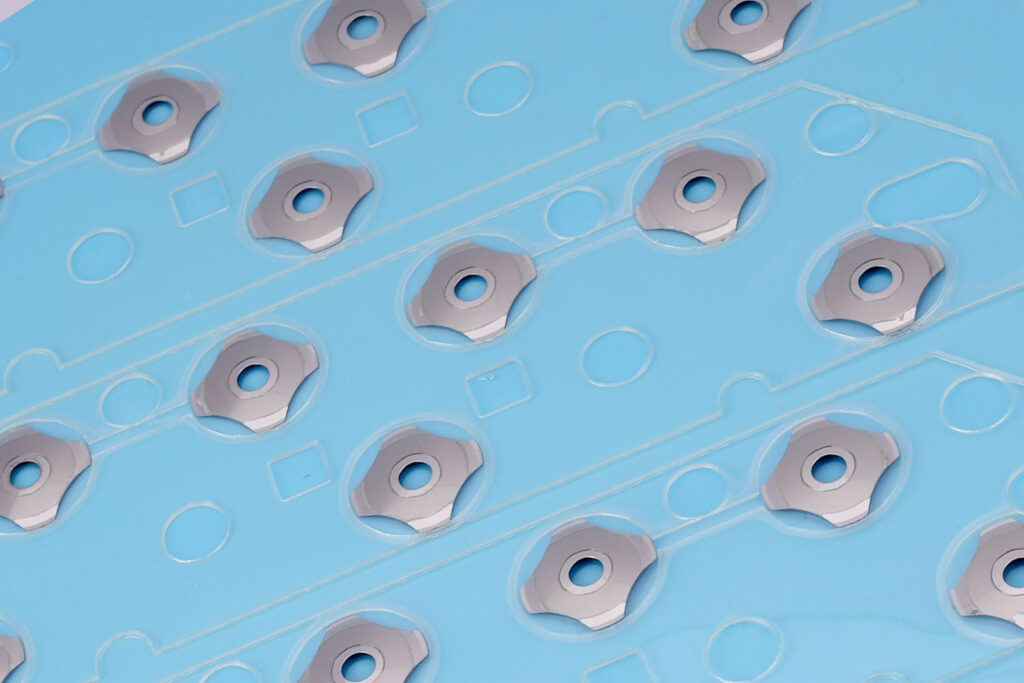

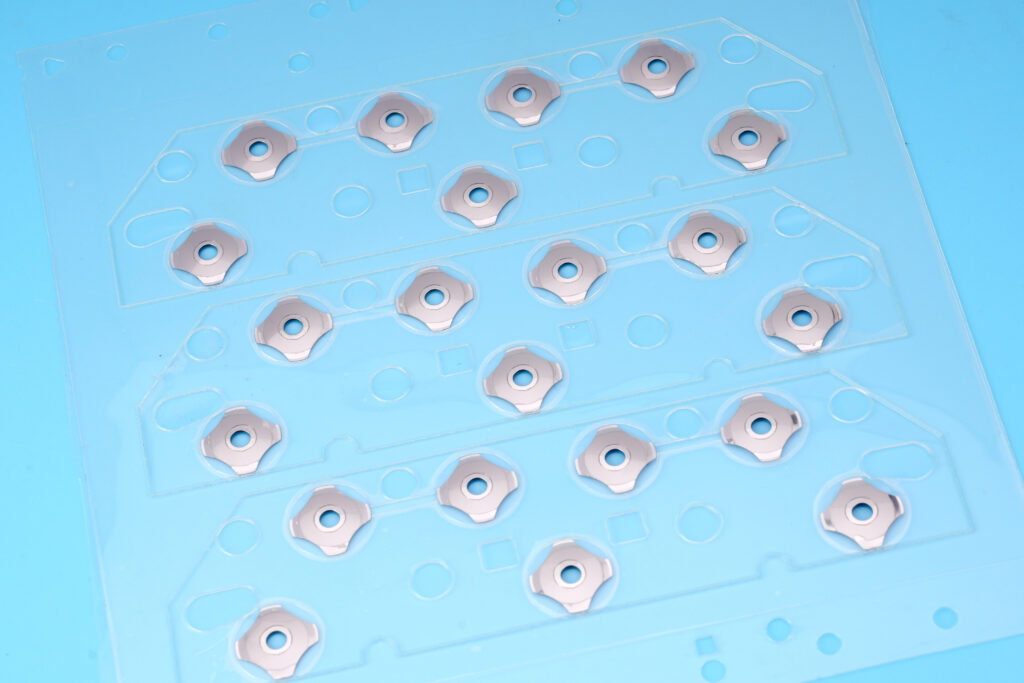

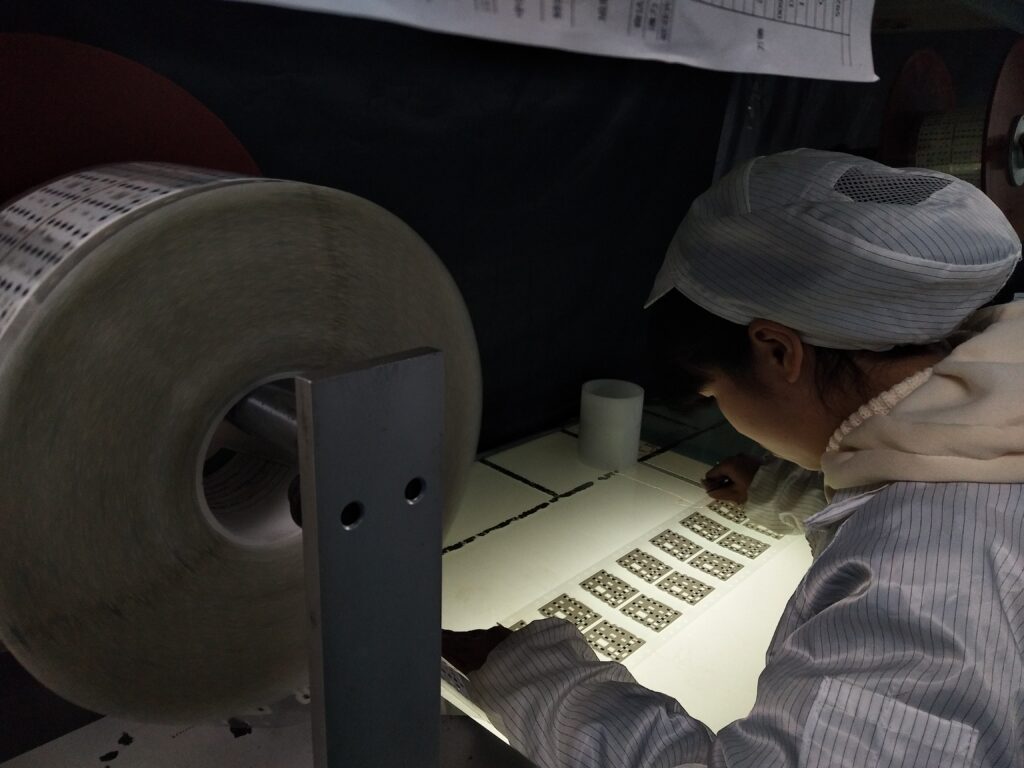

BEST Technology has been deeply involved in the dome array industry for many years, building a full-chain service system centered on “customer needs.” From initial solution communication, customized design, and rapid prototyping to mass production, strict quality inspection, and on-time delivery, each step has a standardized control process, with a professional team following up throughout to ensure efficient project progress and stable, controllable product quality, giving clients peace of mind.

Why choose us? (BEST Technology Core Advantages)

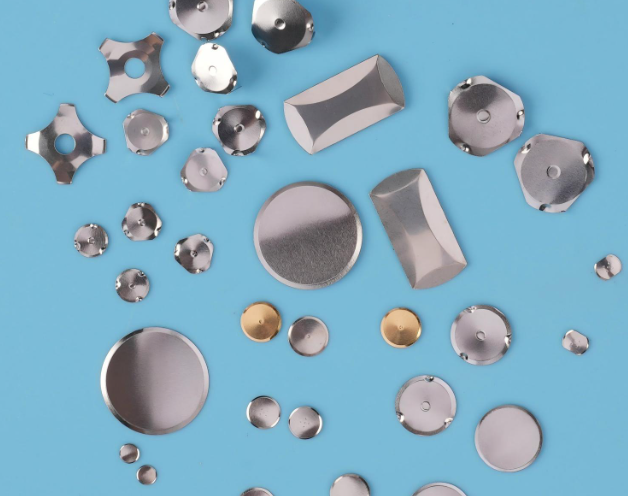

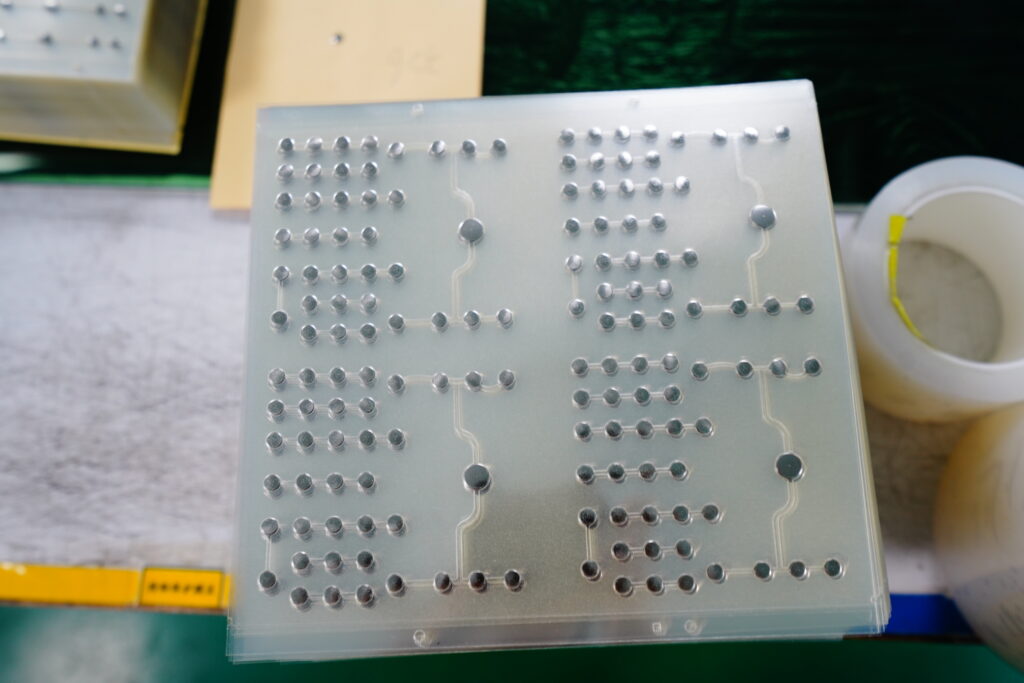

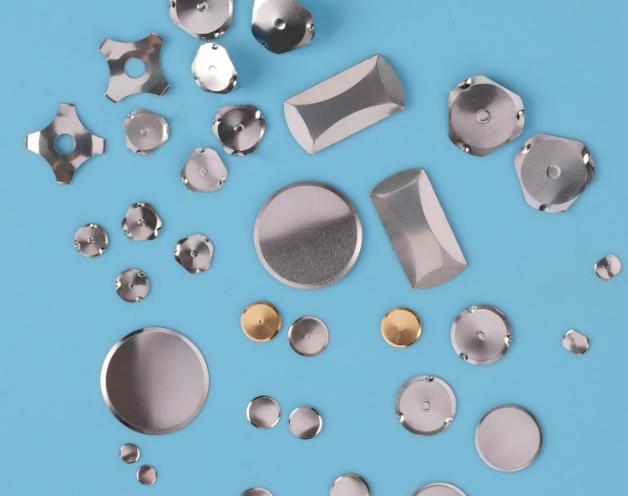

- Technological Strength: Possesses an independent R&D team and core patents, enabling a closed-loop technology cycle from design to manufacturing, precisely adapting to complex application scenarios.

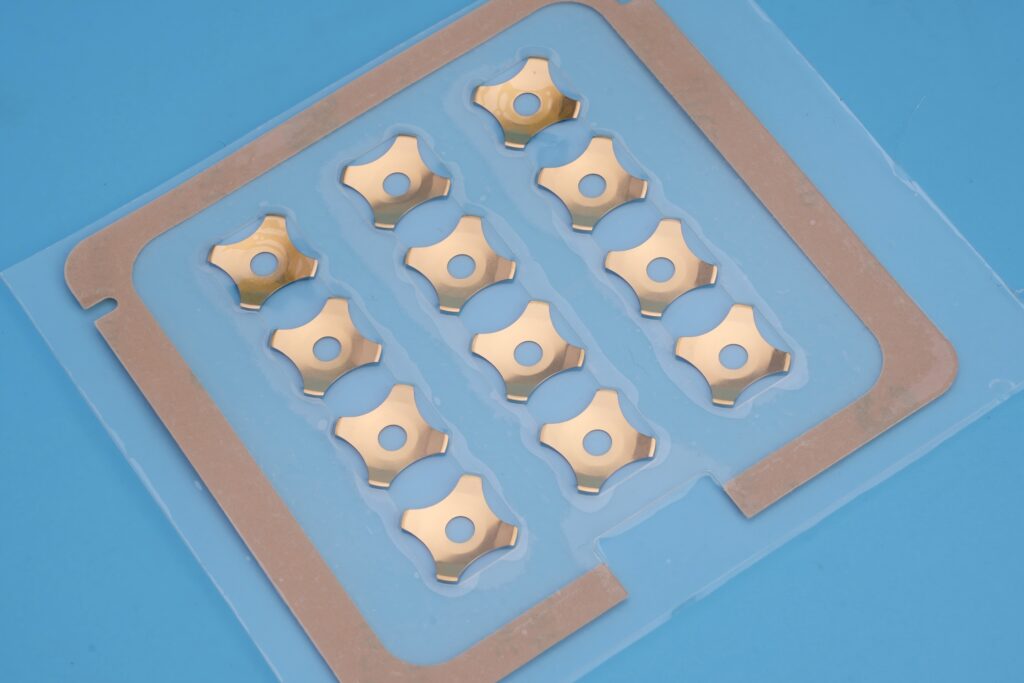

- Production Capacity Guarantee: Equipped with automated production lines and precision testing equipment, monthly production capacity reaches 1 million+ units, meeting the needs of large-volume orders.

- Rapid Response: Prototype delivery within 24 hours, regular orders responded to within 72 hours, and urgent orders are prioritized through a dedicated channel.

- Strict Quality Control: Certified by ISO9001 and TS16949 systems, with a product yield consistently above 99.8%.

- High Customization Capability: Supports full-dimensional customization from materials, dimensions, performance to appearance, enabling rapid implementation of solutions based on customer drawings.

- Efficient Service: Provides technical support, after-sales maintenance, and more efficient communication.

Top 10 dome array manufacturers in Türkiye

| Company Name | Process Capabilities | Advantages |

|---|---|---|

| BEST Technology | metal dome, dome array, SMT mounting, assembly testing, rapid prototyping | Complete technical patents, fast customized response, yield rate 99.8%+ |

| Turkuaz Electronics | injection molding, circuit integration, finished product assembly | Strong mass production capability, stable delivery, high cost-performance ratio |

| Anadolu Precision | precision mold manufacturing, dome array injection molding, performance testing | High product precision, focus on high-end market, strict quality control |

| Marmara Tech | SMT mounting, dome assembly, customized design | Strong adaptability to small-batch orders, short prototyping cycle |

| Aegean Components | injection molding processing, circuit layout, finished product inspection | Mature supply chain, significant cost control advantages, regular products in stock |

| Bosphorus Engineering | full-process customization, mold development, mass production | Strong engineering capabilities, outstanding ability to implement complex solutions |

| Taurus Manufacturing | precision manufacturing, performance optimization, after-sales support | High product stability, rich industry application experience |

| Istanbul Dome Solutions | rapid prototyping, small-batch production, customized services | Fast response, convenient communication, flexible adaptation to needs |

| Antalya Precision Tech | injection molding, assembly testing, quality inspection | Localized production base, short delivery cycle, wide service radius |

| Izmir Electronics Group | large-scale production, standardized product supply, customized extensions | Sufficient production capacity, ample stock of standard models, flexible cooperation thresholds |

How to choose a Türkiye DOME ARRAY manufacturer?

- Verify if the manufacturing process capabilities cover your needs (e.g., prototyping, customization, mass production, etc.)

- Verify quality system certifications (whether core certifications such as ISO9001 and TS16949 are complete)

- Understand past cooperation cases, especially experience in projects within the same industry

- Assess whether the prototyping and mass production delivery cycles meet project milestones

- Examine customization response capabilities and whether they support the implementation of drawings-based solutions

- Verify the advancement of production and testing equipment to ensure product accuracy

- Understand the after-sales service system and whether it provides technical support and troubleshooting solutions

- Assess price transparency and cost-effectiveness to avoid hidden costs

- Examine localized service capabilities and whether there are nearby service outlets or dedicated teams

- Verify production capacity to ensure that subsequent order expansion needs can be met

Türkiye DOME ARRAY Manufacturer’s Core Pain Points

- Long prototyping cycle (7-15 days) ? BEST Technology offers 24-hour rapid prototyping, with priority processing for urgent orders

- Large product accuracy error (above ±0.1mm) ? BEST Technology uses high-precision equipment, controlling errors within Within ±0.03mm

- Low batch production yield (below 95%) ? BEST Technology’s end-to-end quality inspection ensures a stable yield of 99.8%+.

- Slow response to customized needs (long communication cycle) ? BEST Technology’s professional team provides one-on-one support, delivering a preliminary solution within 24 hours.

- Unstable supply chain (raw material shortages leading to delivery delays) ? BEST Technology’s multi-channel supply chain reserves guarantee a 99% delivery time.

- Design disconnected from actual application (requiring multiple revisions) ? BEST Technology conducts in-depth pre-production needs assessment and optimizes the design based on application scenarios.

- Small batch orders not accepted ? BEST has no minimum order requirement, giving equal importance to small and large batch orders.

How to assess the production capacity of a Türkiye DOME ARRAY manufacturer?

- Review the production equipment list to confirm the availability of core equipment such as precision injection molding and SMT assembly.

- Understand the process control procedures and whether there are standardized operating procedures (SOPs).

- Verify production capacity and inquire about monthly capacity and maximum order acceptance capacity.

- Assess the R&D team’s strength, including whether they possess core technology patents and innovation capabilities.

- Review the quality testing equipment and processes to confirm whether they can cover all testing needs.

- Understand the raw material procurement channels and whether long-term partnerships have been established with high-quality suppliers.

- Verify the scale and layout of the production site and its potential for expansion.

- Inquire about past large-volume order delivery cases to verify production capacity stability.

- Understand the environmental compliance of the production process and whether it meets local policy requirements.

- Assess the professional competence of employees, especially the qualifications of technical and quality control personnel.

How to assess the delivery time of a Türkiye DOME ARRAY manufacturer?

- Confirm whether the standard delivery cycle (e.g., 7-15 days) meets your needs.

- Understand the handling capacity and additional costs of expedited orders.

- Assess supply chain stability and inquire about raw material inventory protection measures.

- Verify the completeness of the order tracking system and whether production progress can be viewed in real time.

- Understand the production scheduling mechanism and whether there are contingency plans for unforeseen circumstances.

- Inquire about the on-time delivery rate of past orders (target ?98%).

- Confirm the logistics cooperation model and whether there are fixed logistics partners to ensure transportation efficiency.

- Verify the communication mechanism and whether there is a dedicated contact person to synchronize delivery progress.

- Inquire about the compensation mechanism for delayed delivery to protect your rights.

Frequently Asked Questions (FAQ) about Türkiye DOME ARRAY Manufacturers

- Q: What information is required for sampling?

A: You need to provide product drawings (2D/3D), material requirements, performance parameters, and application scenario descriptions. We will quickly provide a sampling plan and quotation based on the information.

- Q: What is the minimum order quantity for mass production?

A: No minimum order requirement; small-batch trial production is supported; tiered discounts are available for large-volume orders.

- Q: How do you ensure product quality meets requirements?

A: We sign a quality agreement, clearly defining acceptance standards; we provide three quality inspection reports during production (first article, patrol inspection, and final inspection); we support on-site customer inspections or third-party testing.

- Q: What happens if product quality issues arise?

A: We respond within 24 hours of receiving feedback and provide a solution within 48 hours; for quality issues not caused by the customer, we support free returns and exchanges and bear the logistics costs.

- Q: Can you provide technical support and installation guidance?

A: We provide product technical manuals and installation tutorials.

- Q: What happens if there are delivery delays?

A: We will provide advance warnings of potential delays and negotiate adjustments to the delivery plan; for delays caused by our fault, we will pay liquidated damages as stipulated in the contract.

BEST Technology, as a core enterprise among Turkey’s top 10 dome array manufacturers, leverages its comprehensive advantages in technology, production capacity, and service to fully meet your needs across all scenarios, including prototyping, design, manufacturing, and delivery. We are a trustworthy partner.