What is an N/C Switch?

An NC switch is a type of electrical switch that is commonly used in various electronic and electrical circuits. In its default state, the contacts of a normally closed switch remain in the “closed” position, allowing current to flow through the circuit. When the switch is activated, it opens, interrupting the current flow.

NC switches are essential in many applications, such as controlling power to specific parts of a system or triggering safety mechanisms. The main idea behind an NC switch is that it is “closed” when not activated and “opens” when it is activated.

What Does NC Mean on a Switch?

The abbreviation NC on a switch stands for Normally Closed. This indicates the switch’s default state when it is not being actively pressed or triggered. In the Normally Closed position, the switch connects two contacts, allowing current to flow freely. When you press or activate the switch, the contacts open, cutting off the flow of current.

Is NC On or Off?

An NC switch is “on” when it is in the normally closed position. In other words, when the switch has not been activated, the circuit is complete, and current flows through the switch. It only turns “off” when the switch is pressed or triggered, causing the contacts to open and interrupt the current.

So, in its natural state, the NC switch is considered “on” because the current is flowing through it. It’s only “off” when the switch opens, preventing the flow of current.

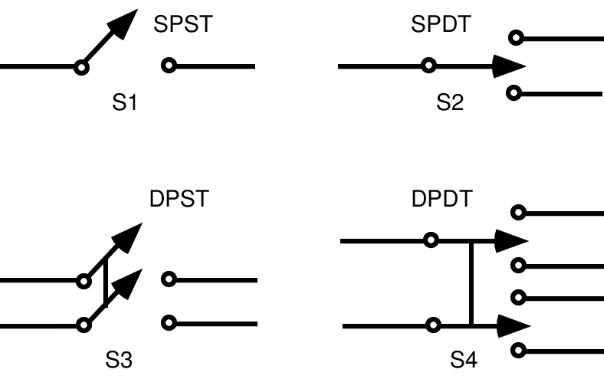

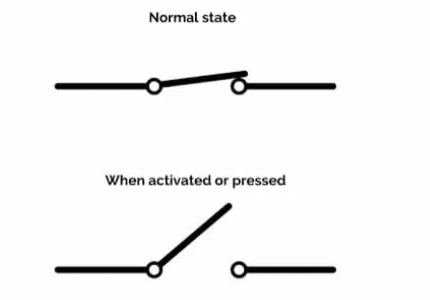

N/C Switch Diagram

Here’s a simple diagram to help you understand how a Normally Closed (NC) switch works:

In this diagram:

- The switch is normally in the “closed” position, allowing current to flow through the circuit.

- When the switch is activated (pressed or triggered), it opens, stopping the flow of electricity.

This diagram is the basic representation of an NC switch used in various circuits.

What is the Difference Between an NC Switch and a NO Switch?

An NC switch and an NO switch are both fundamental components in electrical circuits, but they function differently.

NC Switch (Normally Closed): As we’ve discussed earlier, the NC switch is closed by default. This means when the switch is not activated, the circuit is complete, allowing current to flow. When the switch is triggered (pressed or otherwise activated), it opens, interrupting the current flow.

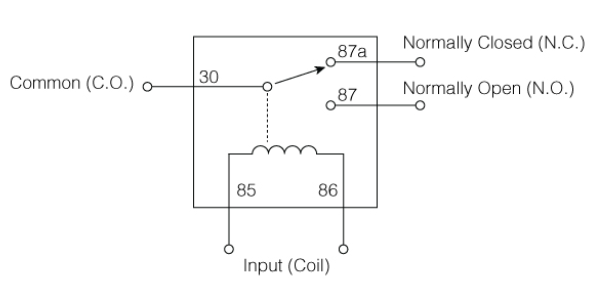

NO Switch (Normally Open): The NO switch is the opposite. In its default state, the switch is open, meaning the circuit is incomplete and no current flows. When the switch is activated (pressed or triggered), it closes, completing the circuit and allowing current to pass through. Below is the circuit diagram of these two types:

Key Differences:

- Default State:

NC: The switch is closed by default.

NO: The switch is open by default.

- Activation:

NC: Pressing or activating the switch opens the circuit, stopping current flow.

NO: Pressing or activating the switch closes the circuit, allowing current to flow.

- Application:

NC switches are often used in safety circuits where the system should be active unless manually disabled (e.g., emergency stop buttons).

NO switches are commonly used where the circuit needs to remain off until activated (e.g., light switches).

How Does an NC Button Work?

An NC button operates similarly to an NC switch. When the button is in its default (unpressed) state, the circuit is closed, and current flows. Pressing the button interrupts the flow of current by opening the switch contacts.

For example, if you have a safety system that needs to be deactivated only when a button is pressed, an NC button is ideal. The system would remain active as long as the button remains unpressed (normally closed), and pressing it would disable the system (open the circuit).

How Do I Know When a Switch is Off?

To know when an NC switch is off, look for the following:

- Visual Indicators: Some switches have indicators, such as LED lights or labels, to show whether the switch is in the “on” or “off” state.

- Physical Position: The position of the switch can also tell you its state. If the switch is pressed or toggled, it will show as “off” (open position). When not pressed, it’s in the closed state (on).

- Multimeter Measurement: You can use a multimeter to measure the continuity of the switch. If the switch is open, the meter will show no continuity, indicating the switch is off.

By using these simple methods, you can easily identify when an NC switch is off.

What is an Example of a Normally Closed Switch?

An excellent example of an NC switch is the doorbell switch. The switch is normally closed when the doorbell button is not pressed. This keeps the circuit active, allowing the chime to sound when you press the button.

Another common example is the emergency stop button in machines or industrial equipment. The button stays in a normally closed state, keeping the machine running until the button is pressed to stop it.

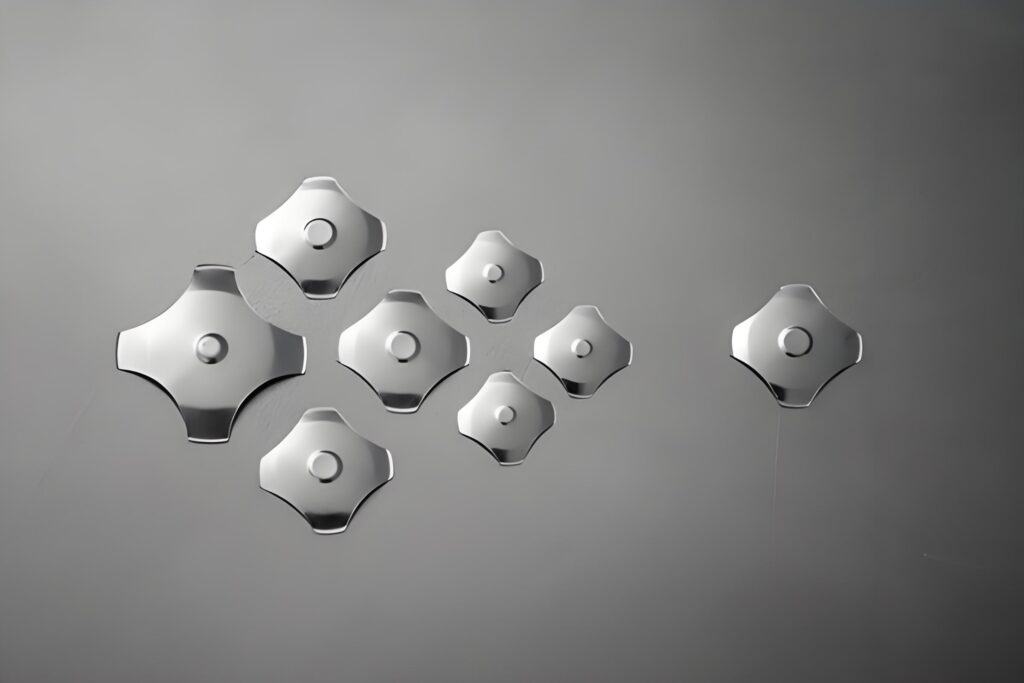

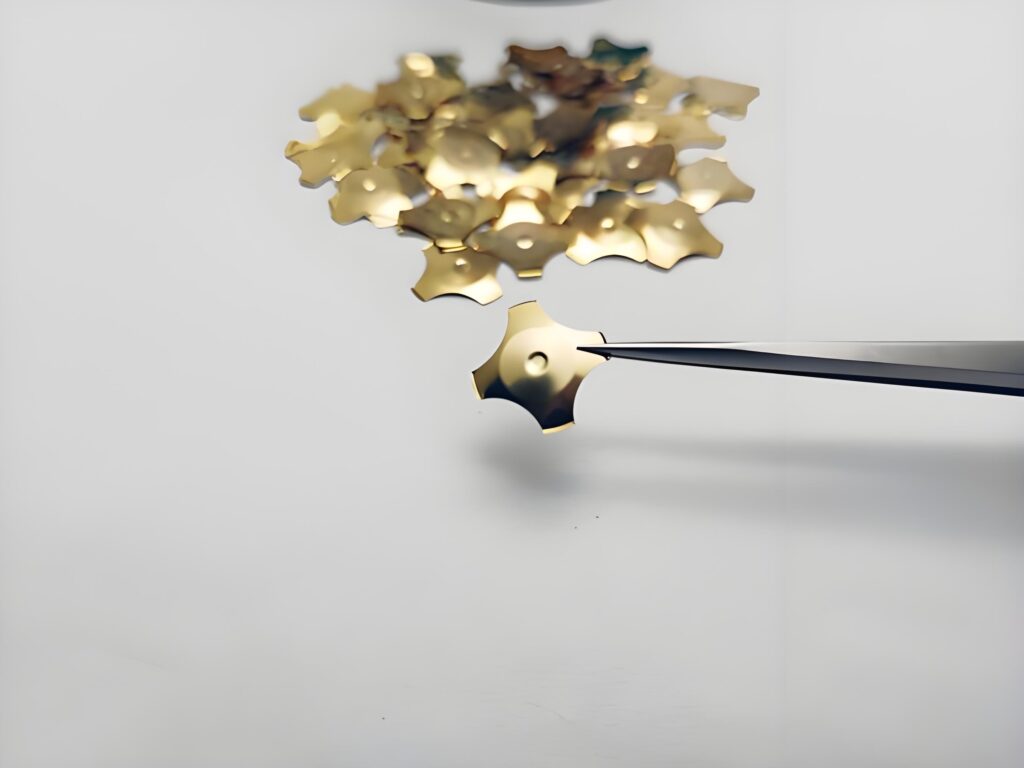

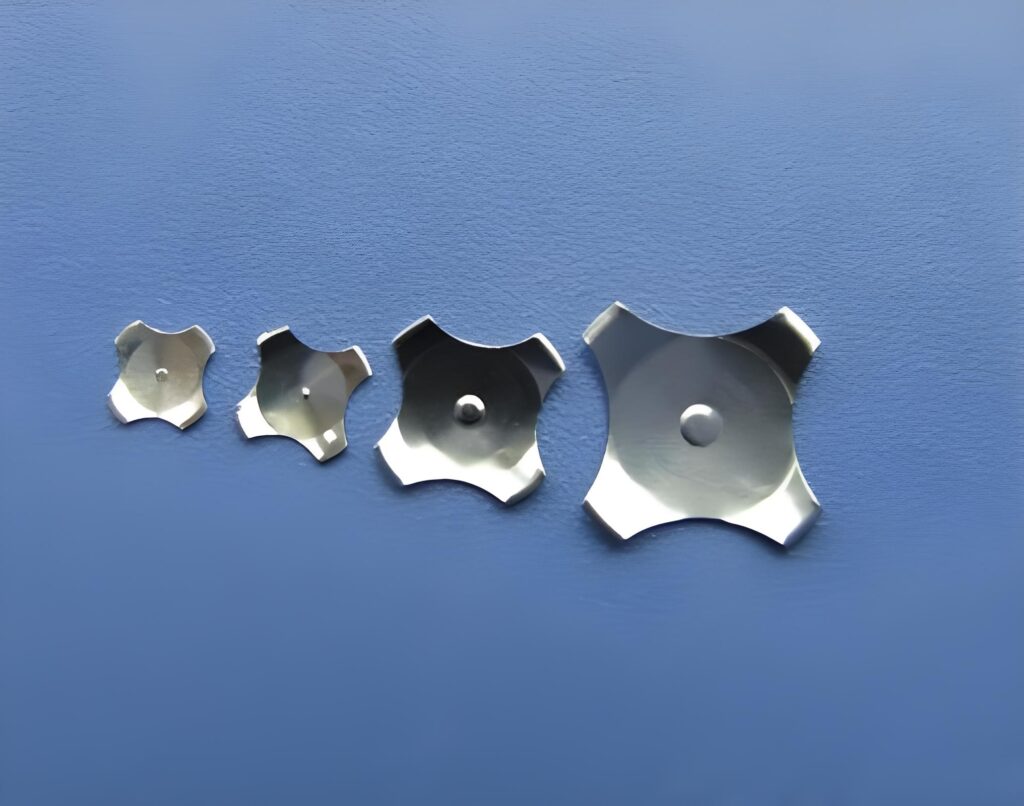

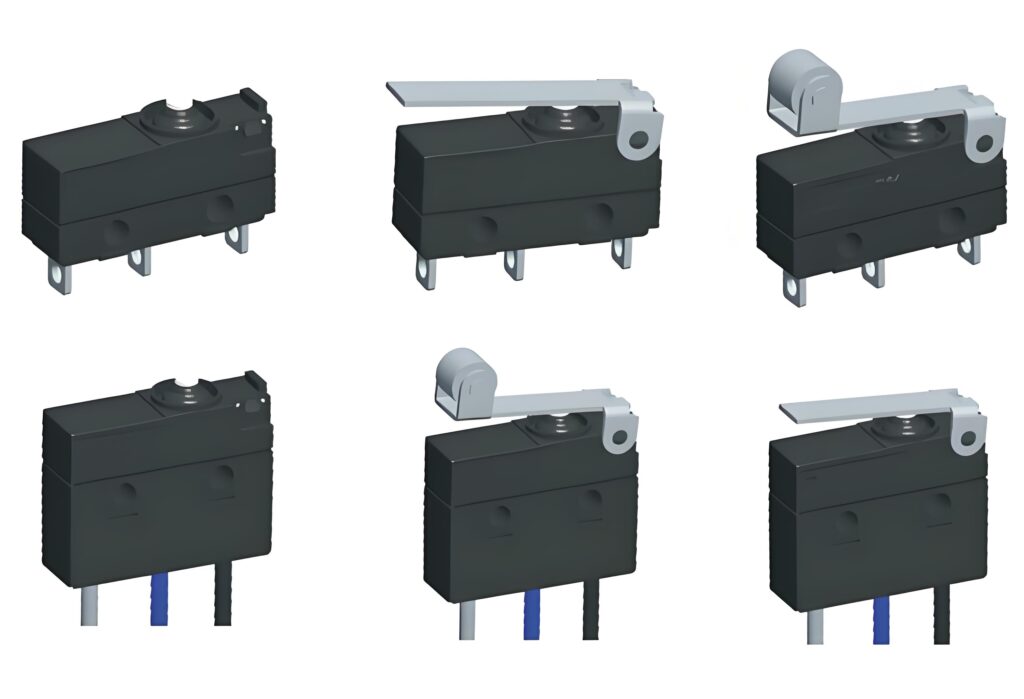

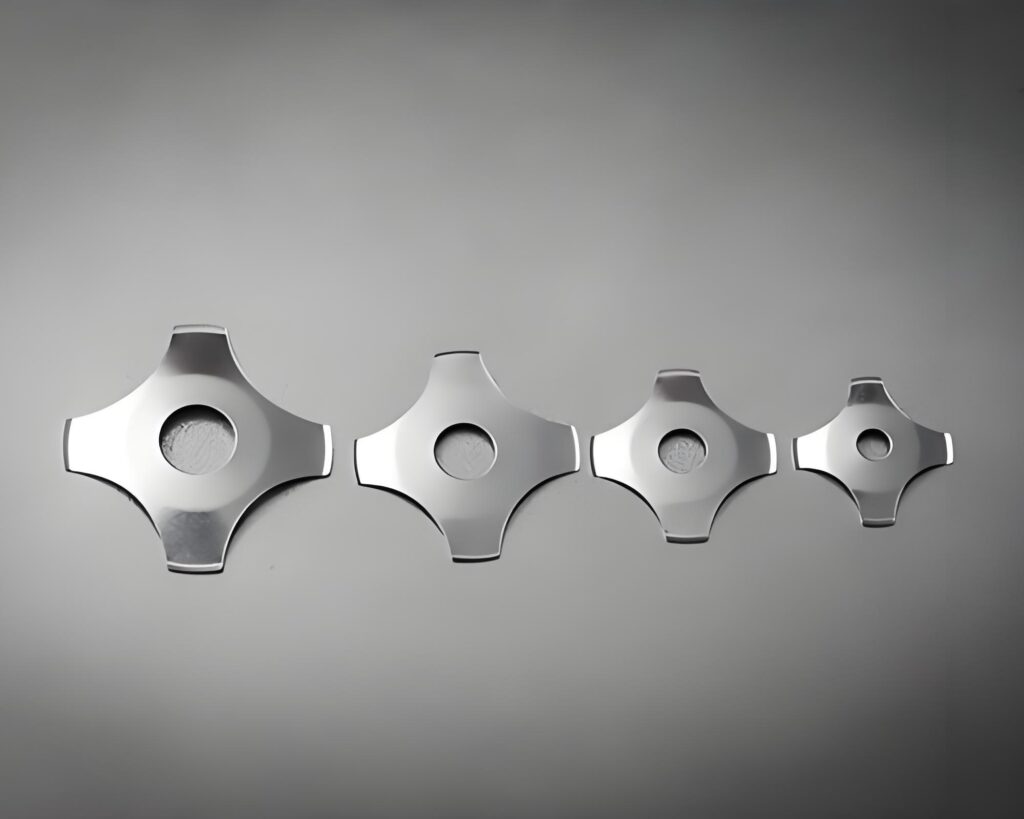

Whether you’re working with safety systems, control circuits, or general electrical applications, incorporating NC switches allows for efficient and reliable operation. If you’re looking for high-quality NC switches, choose Best Technology N/C switches or Best Technology Metal Domes. Since established in HK from 2006, we have over 18 years in this industry. We deeply know this product and can offer valuable suggestions to your projects. Contact us for more information!