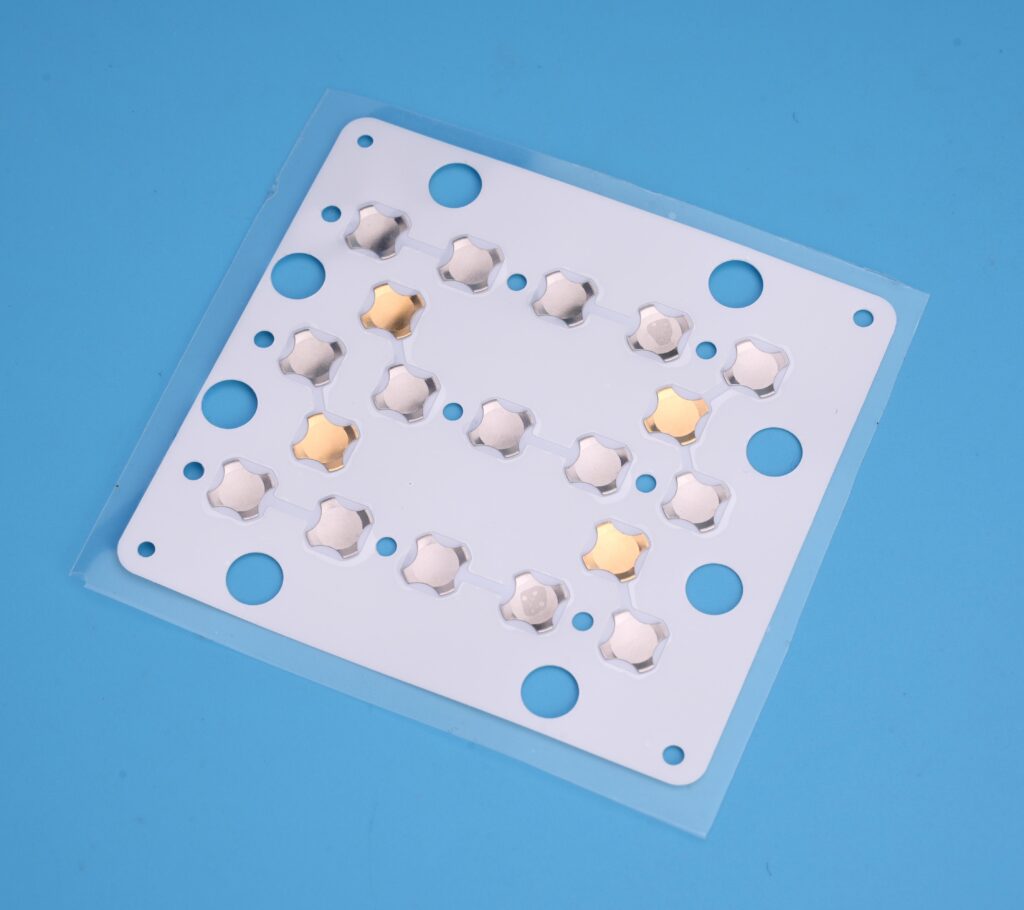

Tactile dome switch is a switch that uses the elastic deformation of a metal dome to provide tactile feedback. When pressed, the dome contacts the circuit board and conducts; when released, the dome returns to its original state and the circuit is disconnected. This type of switch is widely used in membrane switches and touch switches, providing clear tactile feedback and reliable electrical performance.

What is a dome switch?

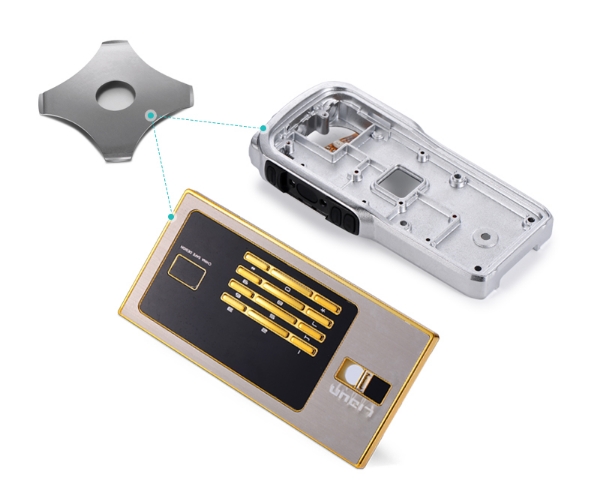

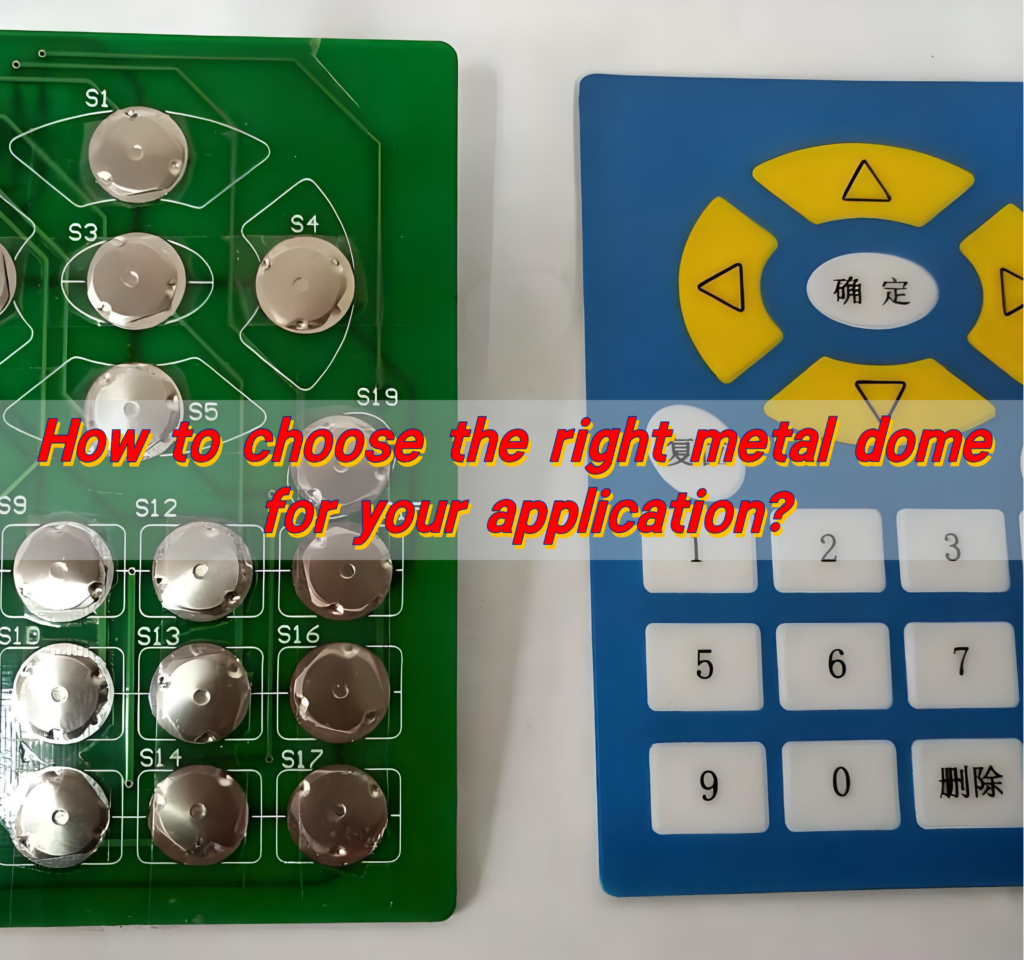

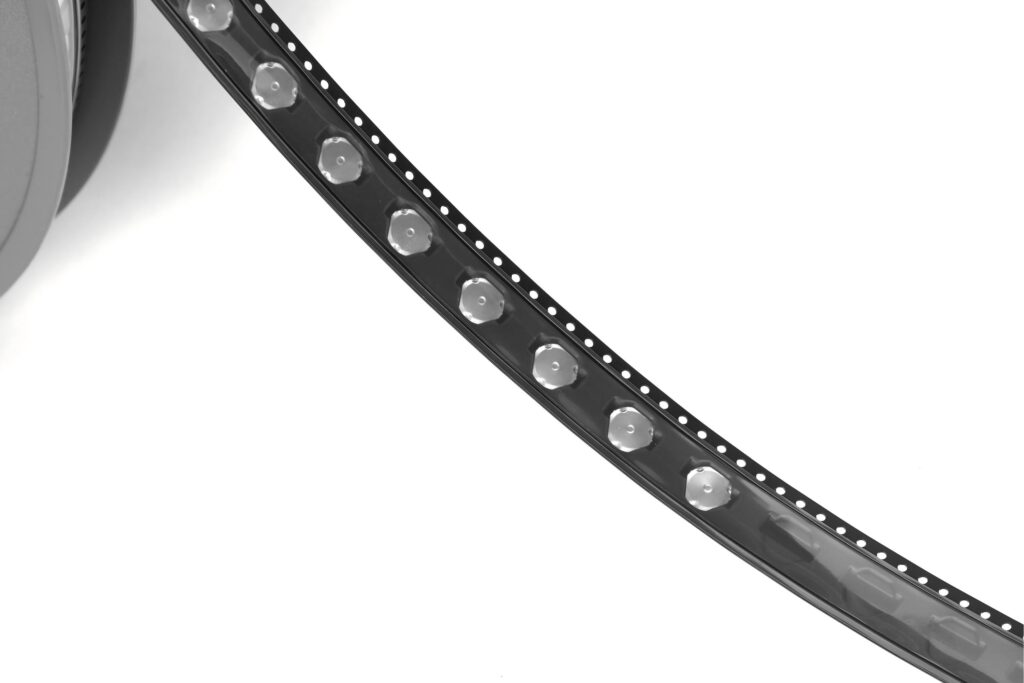

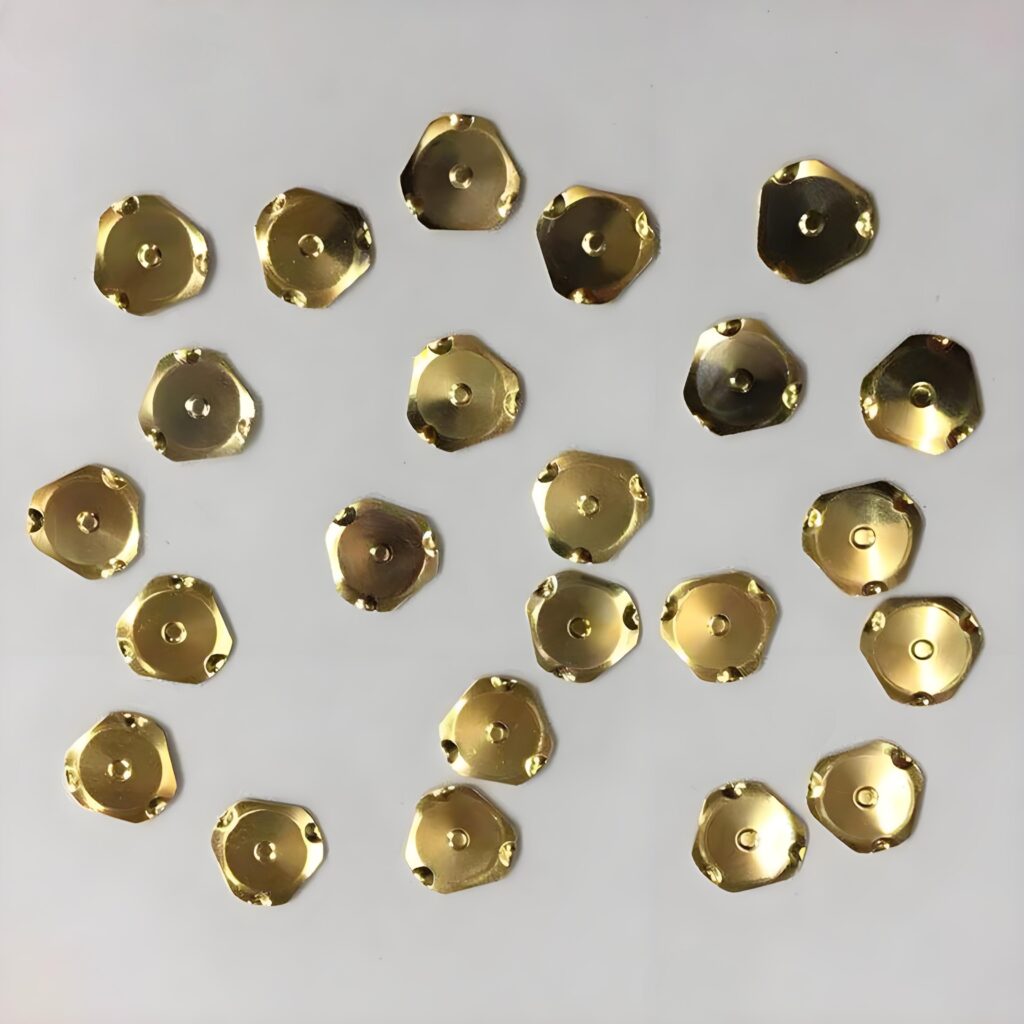

Dome switch is a type of electrical switch that uses a small, flexible metal dome to complete the circuit when pressed. The dome, made of stainless steel, sits on a PCB and is covered by a top layer. Once pressed, the dome collapses, bridging contact points below to send a signal.

This action produces a tactile response. It gives a crisp, audible click that lets users know the action has been triggered. The quick snap-back action of the metal dome enhances the user’s experience. Because of this, dome switches are widely used in environments where reliability and tactile feedback are key.

Are dome switches good?

Dome switches are not only good; they are outstanding in many applications. Their build allows for consistent performance over thousands to millions of presses. They don’t wear out quickly like other types of switches.

The metal dome gives a premium feel, making every press satisfying. Their tactile nature reduces errors because users can instantly feel feedback. It helps improve typing speed and operational accuracy, especially in critical fields like healthcare and aerospace.

On top of that, their flat design makes them compact. They save space while providing robust functionality. With water-resistant and dustproof options available, dome switches also work well in challenging environments.

What is the difference between mechanical and dome switches?

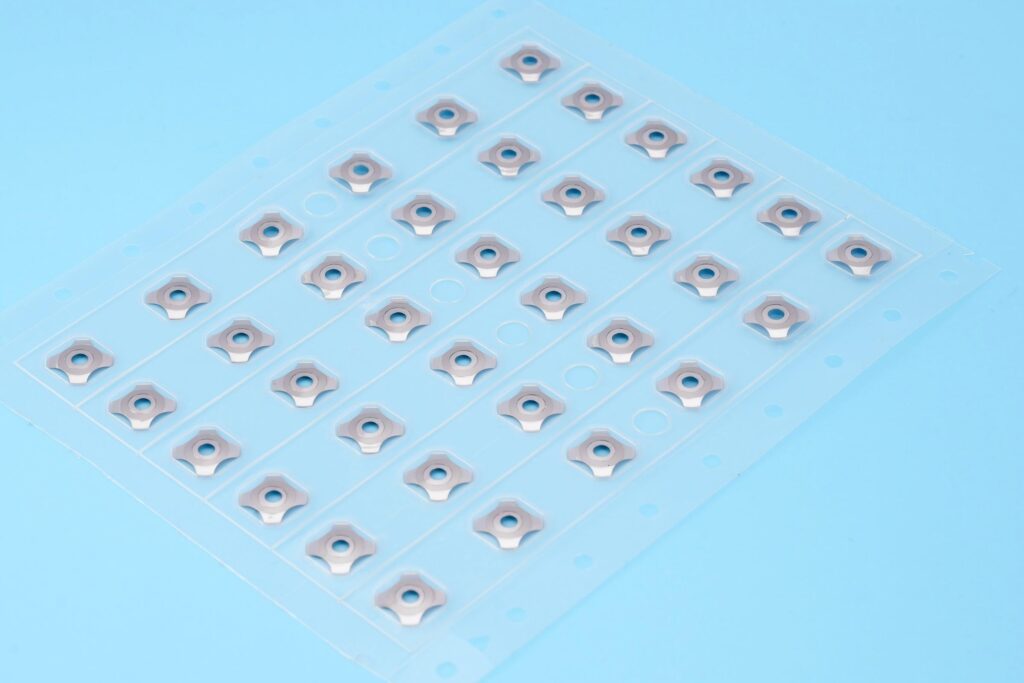

Mechanical switches and dome switches differ in feel, build, and lifespan. Mechanical switches use moving parts with individual mechanisms for each key.

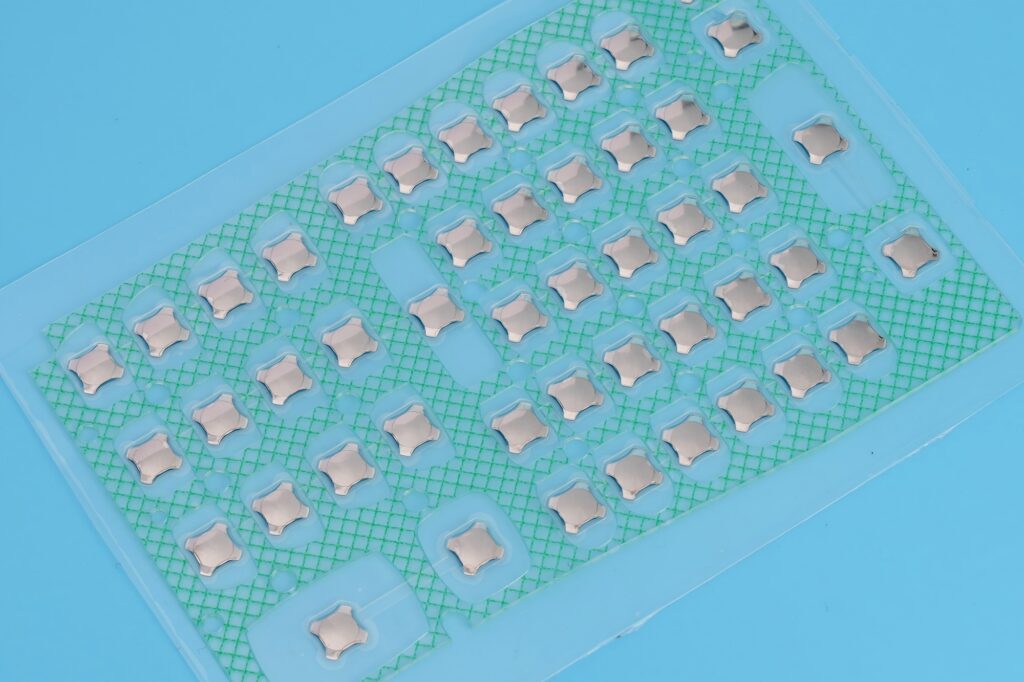

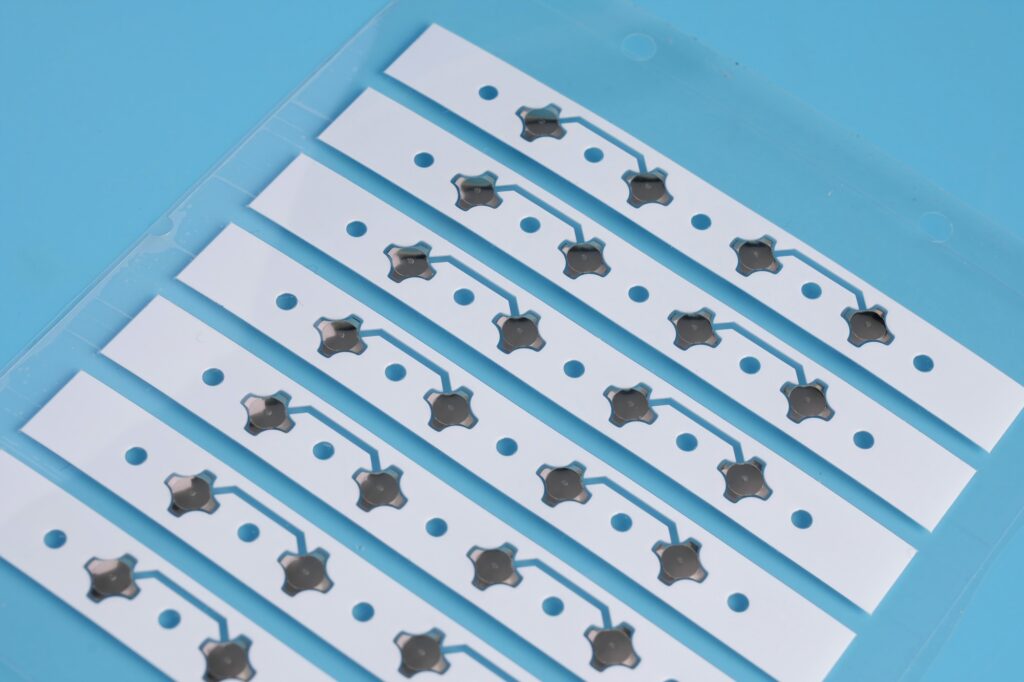

Dome switches, on the other hand, use a single sheet of metal domes on a PCB. The press collapses the dome to complete the circuit. They are quieter, more compact, and often more affordable. While mechanical switches can last longer, dome switches provide an excellent balance between tactile feel, performance, and price.

For users who want a responsive press without the bulk and noise, dome switches win.

What is the difference between membrane and dome switch?

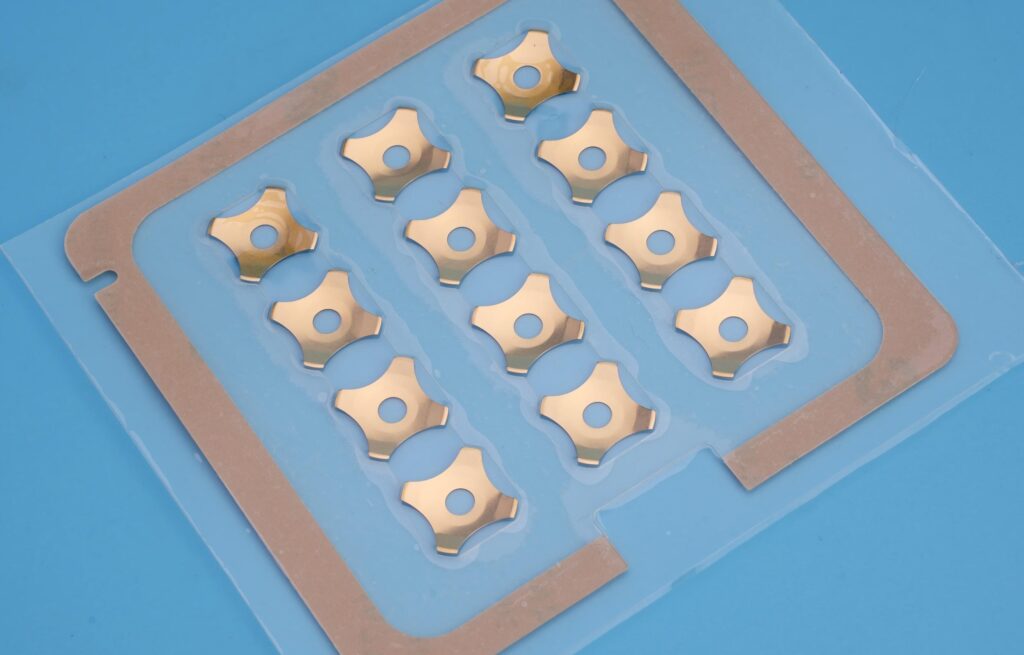

While often confused, membrane and dome switches are not the same. A membrane switch uses pressure pads with conductive traces printed on flexible layers. They usually don’t offer tactile feedback. When pressed, users may not feel anything beyond a soft push.

A dome switch, however, integrates a metal dome over a PCB. It adds tactile feedback, enhancing the user experience. This tactile snap helps users know when a function has been activated. It reduces mispresses and improves control.

Moreover, dome switches typically respond faster and have better durability than membrane-only designs. If you want a soft press, membrane switches may suit you.

Dome switch vs membrane: which is better?

If your goal is durability, speed, and a solid tactile feel, dome switches outperform membrane ones. While both are used in many consumer electronics, the added feedback of a metal dome makes dome switches stand out.

In professional environments—where error-free operation is crucial—dome switches provide peace of mind. They allow operators to feel every input. This reduces chances of repeated presses or missed commands.

Membrane switches do have their place. They work well in low-cost or disposable applications. But when quality matters, dome switches bring more to the table.

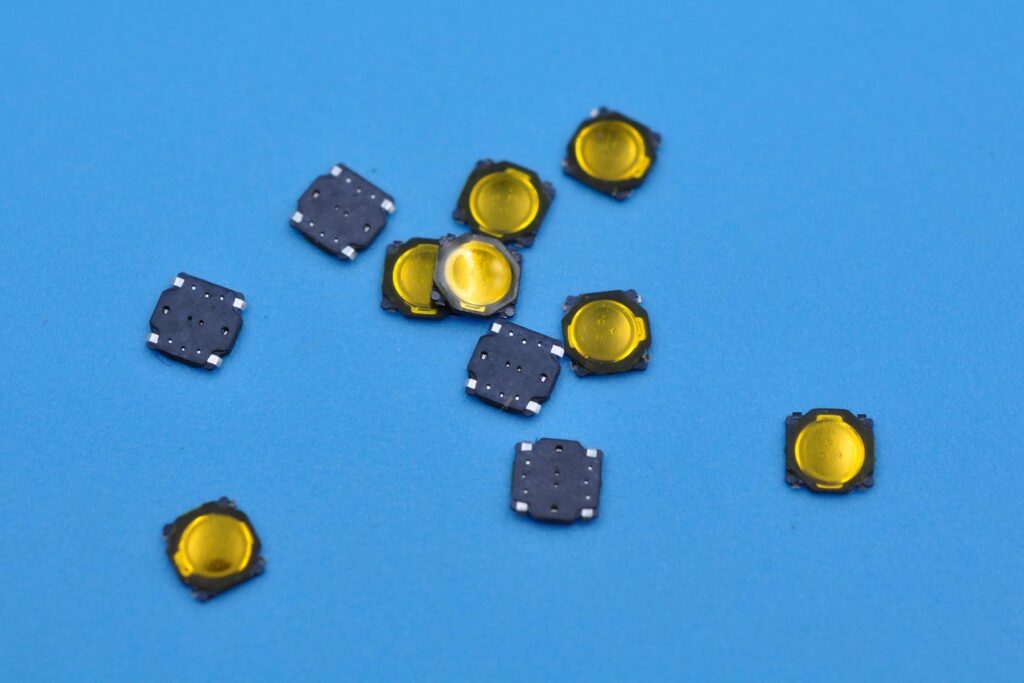

What is a rubber dome switch?

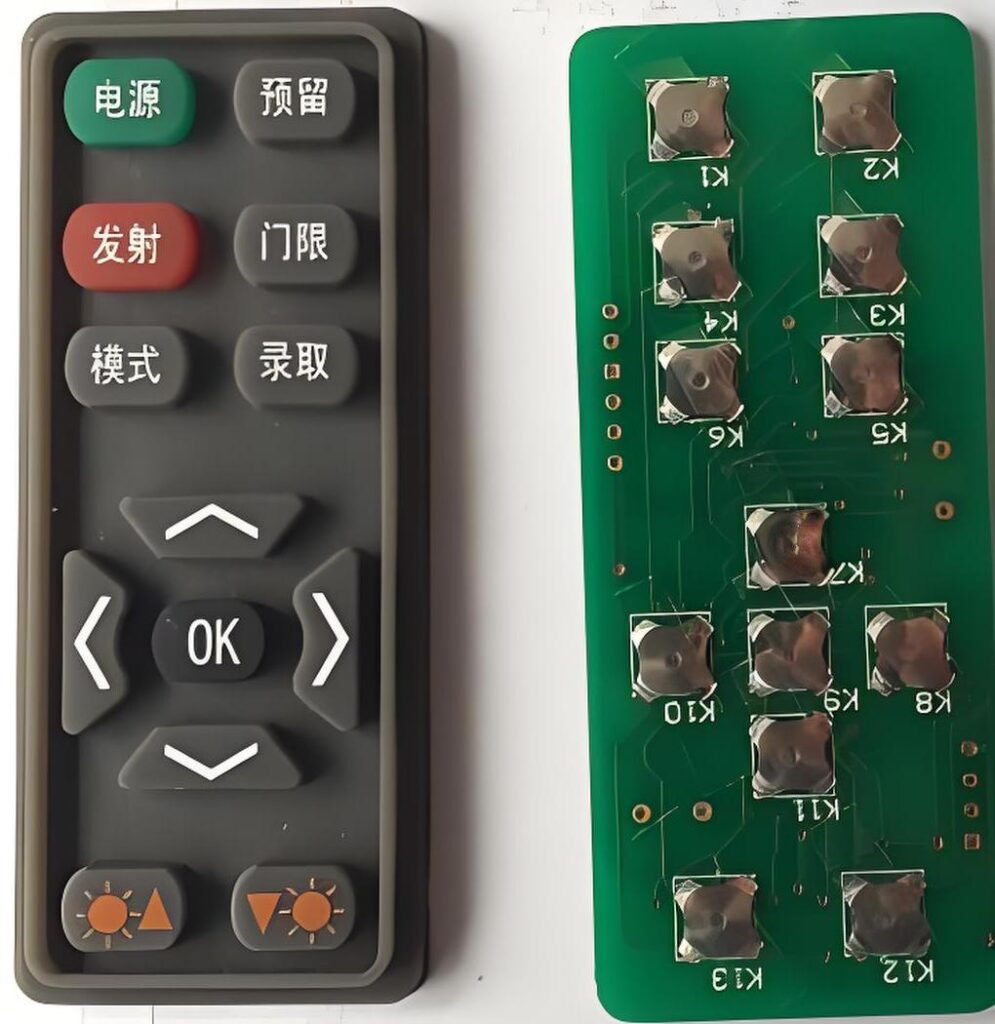

Rubber dome switch is a variation of the dome switch that uses a rubber or silicone dome instead of metal. Found mostly in traditional keyboards, the rubber dome collapses when pressed, making contact with the circuit underneath.

Though affordable and quiet, rubber dome switches lack the sharp tactile feedback of metal domes. They feel softer and less precise. Over time, the rubber can wear out, leading to mushy or inconsistent response.

Compared to metal dome switches, rubber dome types have a shorter lifespan and reduced reliability.

Dome switch vs conductive rubber: what’s the difference?

Conductive rubber switches use carbon or graphite-based rubber pads to bridge the circuit when pressed. They’re flexible, soft, and quiet. They are often seen in remote controls and toys.

Dome switches rely on a pre-formed metal dome that snaps to provide feedback. This mechanical snap gives a crisp feel, making it ideal for professional interfaces.

In summary, conductive rubber is soft and low-cost. Dome switches are more precise, faster, and more satisfying to use. If feedback, reliability, and responsiveness matter, metal dome switches are the superior choice.

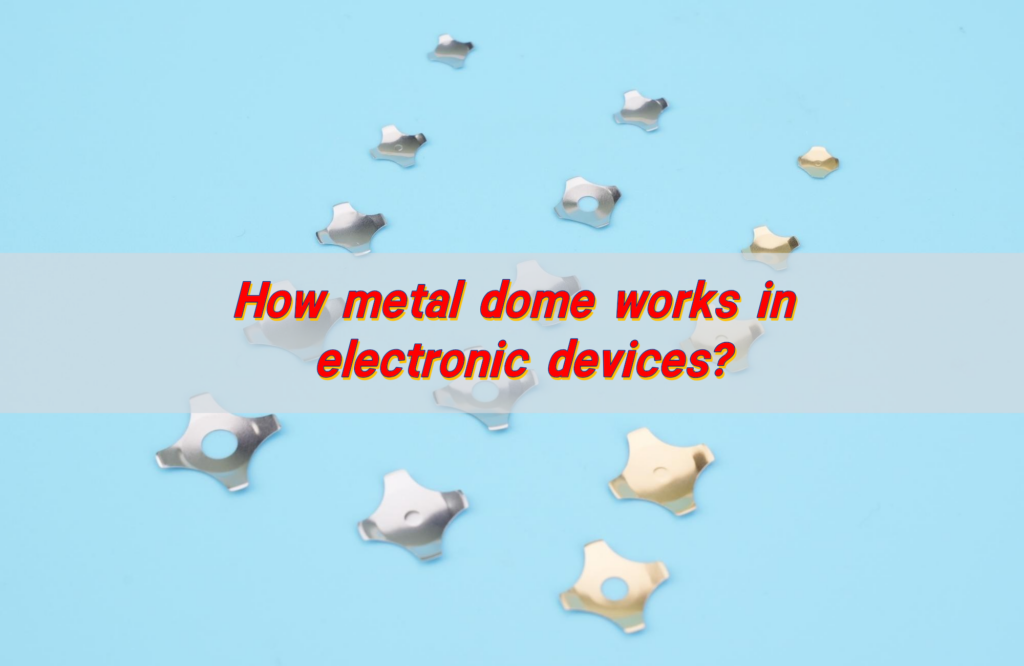

How does a dome switch keyboard work?

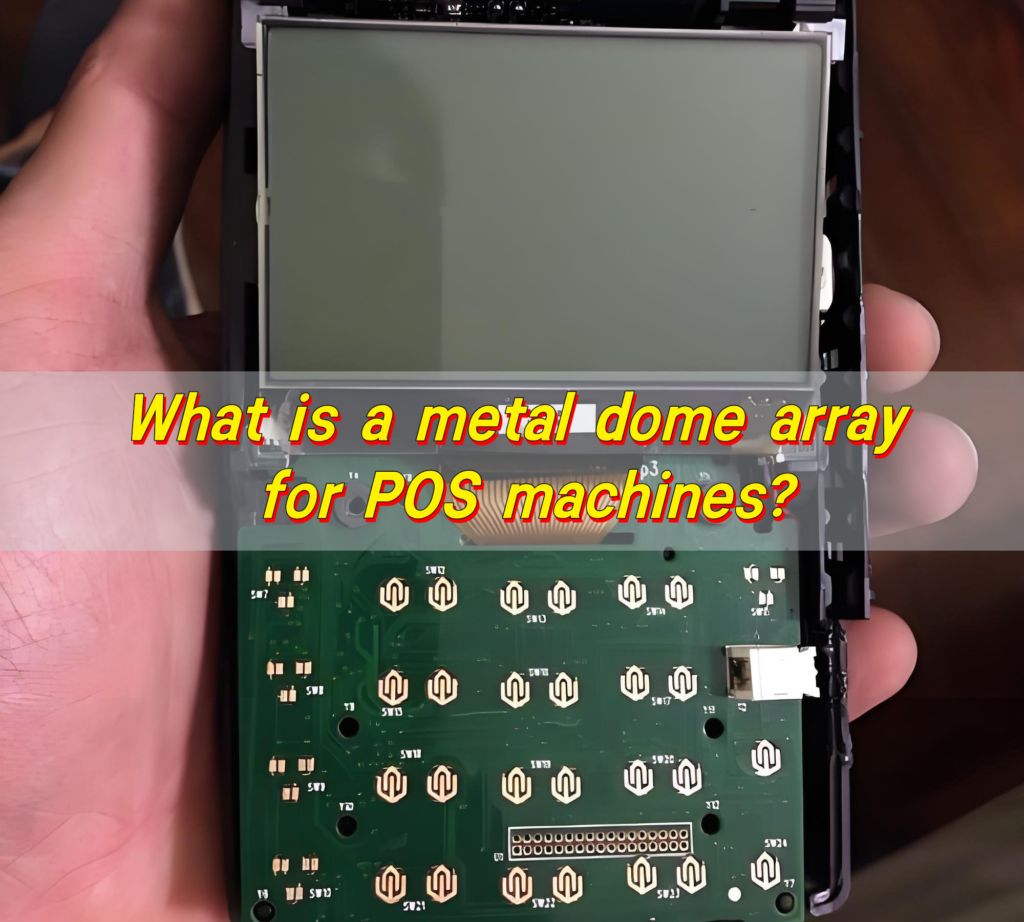

Dome switch keyboard combines dome switch technology with a keyboard layout. Each keypress pushes down a top layer, which in turn presses the metal dome beneath. Once collapsed, the dome closes the circuit on the PCB, sending a signal.

This mechanism provides both an electrical connection and tactile confirmation. The result is a compact, responsive keyboard. These are used in medical tools, rugged devices, and other industries where performance matters.

Some keyboards even combine rubber and metal domes to balance cost and feel. However, the pure metal dome type offers the sharpest, most reliable feedback.

Conclusion:

Dome switch is a reliable choice for all walks of life because of its sensitive touch, compact size and durability. From industrial machinery to medical panels, dome switches improve human-machine interaction. They reduce user fatigue, boost performance, and ensure accurate input.

If you’re looking to integrate dome switch technology into your next project, reach out to us. Contact us: sales@metal-domes.com