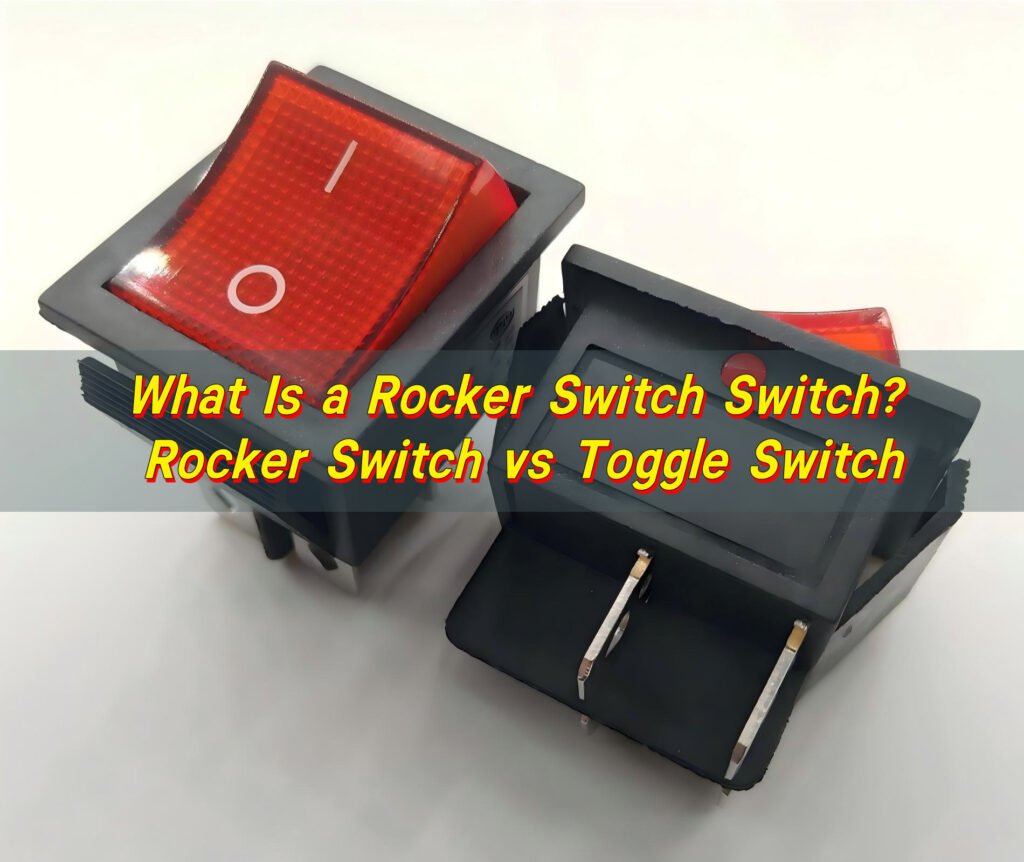

A rocker switch switch is one of the most widely used electromechanical switches in modern products, valued for its clean appearance, intuitive operation, and dependable performance. You encounter it daily, often without noticing, from wall-mounted lighting to industrial control panels and consumer electronics.

What Are Rocker Switches?

A rocker switch is a type of electrical switch that rocks back and forth on a pivot. One side is pressed down to close a circuit, while the opposite side is pressed to open it. The motion feels natural because it mirrors a simple on-and-off gesture, similar to pressing a button on a remote control.

Rocker switches are often rectangular, though round and curved styles also exist. The actuator usually sits flush with the surrounding surface, giving the switch a tidy and modern appearance. Many designs include markings such as “I” and “O,” or text like “ON” and “OFF,” which make the switch state easy to read at a glance.

Several features explain why rocker switches are so common:

- They are simple to operate, even without looking directly at them.

- They provide clear tactile feedback when the state changes.

- They integrate well into flat panels and enclosures.

- They are available in many electrical ratings and configurations.

Rocker switches can be single-pole or multi-pole. They can control one circuit or several at the same time. Some versions include built-in illumination, creating the familiar rocker light switch seen in homes, vehicles, and equipment panels. Others are designed for harsh environments, with sealed housings that resist dust and moisture.

How to Wire a Rocker Switch?

Wiring a rocker switch is usually straightforward, yet it must be done with care to ensure safety and proper function. The exact method depends on the switch type, the number of terminals, and the application voltage.

Most basic rocker switches have three terminals. These are typically labeled as common (COM), normally open (NO), and sometimes normally closed (NC). In many household and low-voltage applications, only two terminals are used: one for the incoming power and one for the outgoing load.

A typical wiring approach follows a clear logic:

- Power enters the switch through the common terminal.

- When the switch is pressed to the ON position, the internal contacts close.

- Current then flows from the common terminal to the output terminal.

- The connected device receives power and operates.

For a lighted rocker switch, there may be an extra terminal for the internal lamp. This lamp often requires a neutral or ground connection, depending on the design. Because of this, wiring a rocker switch with illumination requires closer attention to the wiring diagram provided by the manufacturer.

In a rocker switch panel, multiple switches are mounted together. Each switch may control a different circuit. Panels are common in vehicles, boats, and industrial machines. Wiring in these cases often uses color-coded wires and labeled terminals to reduce mistakes.

What Is the Purpose of a Rocker Switch?

The purpose of a rocker switch is to control the flow of electrical current in a clear and dependable way. It provides a human interface between a power source and an electrical load, allowing users to start or stop a function with minimal effort.

Rocker switches excel in roles where clarity matters. Their position usually indicates their state. When one side is pressed down, users can often see and feel that the circuit is active.

Common purposes of rocker switches include:

- Turning lights on and off in homes and offices.

- Controlling power to appliances and equipment.

- Managing subsystems in vehicles, such as auxiliary lights or fans.

- Enabling or disabling functions in industrial control panels.

In many designs, the rocker switch also serves an aesthetic purpose. Its clean lines and low profile help products look more refined. This is particularly important in consumer electronics and architectural lighting, where appearance influences buying decisions.

How Does a Rocker Switch Work?

Inside a rocker switch is a simple but robust mechanical system. The external actuator is connected to a pivot mechanism. When you press one side of the rocker, the pivot tilts, moving an internal contact assembly.

In the OFF position, the contacts are separated. This creates an open circuit, so current cannot flow. When you press the rocker to the ON position, the contacts move together and touch. This closes the circuit and allows current to pass through the switch.

Many rocker switches use spring-loaded contacts. These springs ensure that the contacts snap firmly into place. The snapping action provides tactile feedback and helps maintain good electrical contact. Firm contact reduces resistance and heat buildup, which improves long-term reliability.

In a lighted rocker switch, the internal lamp is wired in parallel or series with the main circuit. When power flows, the lamp illuminates. This illumination helps users see the switch state in low-light conditions and adds a visual cue that the circuit is active.

Which Is Better, a Toggle or a Rocker Switch?

The question of which is better often depends on context rather than absolute performance. Each offers advantages that suit different use cases.

Rocker switches tend to feel more modern. Their broad surface is easy to press, even with gloves. Their flush design reduces the chance of accidental activation. These traits make them popular in consumer products and professional equipment alike.

Toggle switches, by contrast, use a lever that moves up and down or side to side. They provide very clear physical feedback and are easy to operate in tight spaces. Some users prefer toggles for their mechanical feel and visual certainty.

In many modern designs, rocker switches are chosen because they integrate smoothly into flat panels. They also allow designers to add illumination and symbols directly on the actuator. This improves usability without adding complexity.

Rocker Switch vs Toggle Switch

Comparing a rocker switch vs toggle switch reveals differences in form, feel, and application.

| Comparison Aspect | Rocker Switch | Toggle Switch |

|---|---|---|

| Operating motion | Presses back and forth on a central pivot | Flips a lever up/down or side to side |

| User interaction | Broad surface, easy to press with a finger | Narrow lever, requires a more deliberate grip |

| Panel integration | Sits nearly flush with the panel surface | Protrudes outward from the panel |

| Accidental activation | Lower risk due to flat profile | Higher risk if brushed or bumped |

| Visual clarity | State often shown by symbols or illumination | State shown by lever position |

| Customization options | Easily supports colors, icons, and lighting | Limited customization, mostly mechanical |

| Typical environments | Homes, vehicles, consumer and medical devices | Industrial equipment, legacy systems |

| Aesthetic impression | Modern, clean, and integrated | Traditional, mechanical, and rugged |

| Frequent switching | Well suited for repeated on/off cycles | Well suited for firm, intentional switching |

Toggle switches remain valuable in settings where tactile certainty and visible mechanical position are more important than surface flushness. Both solutions are proven, and the better choice depends on the operating environment, user expectations, and overall product design goals.

How to Tell If a Rocker Switch Is Bad?

Like all mechanical components, rocker switches can wear out over time.

One common sign is inconsistent operation. If the connected device turns on and off unpredictably, the internal contacts may be worn or contaminated. Another sign is a loose or spongy feel when pressing the rocker, which suggests mechanical fatigue.

Electrical symptoms can also appear. A bad rocker switch may feel warm to the touch. This can indicate increased resistance at the contacts. In lighted rocker switches, the indicator lamp may flicker or fail to illuminate.

Replacing a faulty rocker switch is usually straightforward. Timely replacement restores reliability and protects the connected equipment.

Where Are Rocker Switches Commonly Used?

Rocker switches appear in a wide range of settings because they adapt easily to different requirements.

In residential spaces, the rocker light switch has become a standard. It replaced older toggle-style wall switches in many regions because it is easier to operate and visually cleaner.

In vehicles, rocker switches control auxiliary functions such as lights, heaters, and pumps. Rocker switch panels allow multiple functions to be grouped together.

Industrial equipment also relies on rocker switches. They are used to control motors, conveyors, and control circuits. In these environments, switches are often rated for higher currents and may include sealing for protection against dust and moisture.

Consumer electronics, medical devices, and office equipment also make extensive use of rocker switches. Designers value their low profile and clear state indication.

Across all these uses, the rocker switch remains a trusted interface. Its form has evolved, yet its core function remains the same: simple, reliable control.

Conclusion:

A rocker switch switch is more than a simple component. It is a carefully balanced interface between people and electrical systems. Rocker switches offer intuitive operation, clear feedback, and flexible design options. They wire easily, perform reliably, and fit naturally into modern products.

For further technical details, sourcing, or application support related to rocker switches and metal dome solutions, please contact sales@metal-domes.com