Choosing the best dome array manufacturers in France is a crucial step for ensuring product reliability, tactile consistency, and long-term durability—especially in industries like consumer electronics, medical devices, and industrial control systems.

France hosts several capable dome array suppliers, but when you need high-precision metal domes, fast sampling, and fully customized dome array solutions, BEST Technology stands out as your most dependable choice.

Are you facing these problems?

As a professional dome array manufacturer, we understand the common pain points many French companies encounter during the procurement process:

- Long prototyping cycles and inefficient communication leading to project delays

- Inconsistent dome feel, unstable rebound force, and significant batch variations

- Suppliers lacking industrial-grade quality systems, unable to guarantee long-term mass production

- Insufficient design support, unable to provide reasonable structural optimization suggestions

- Weak customization capabilities, only offering standard specifications

- Limited large-scale production capacity, unable to guarantee delivery times during peak periods

Why choose us? (Core Advantages)

As a leading global manufacturer of metal domes and dome arrays, BEST Technology provides French customers with highly stable, consistent, and traceable complete solutions. Our core advantages include:

- 20+ years of focus on metal domes and dome arrays — extensive experience and expertise in electrical performance, tactile consistency, and structural reliability control.

- ±0.05mm high-precision array positioning — ensuring precise key response for high-end communication equipment, industrial control, and medical electronics.

- Fully automated molding + visual inspection — 35% improvement in tactile consistency and a significant reduction in defect rate.

- 48-hour prototyping response, 7-day expedited delivery — ideal for French customers who need rapid design verification.

- Deep OEM & ODM customization capabilities — from metal domes to complete array structures, all can be customized.

- Long-term cooperation certification with international clients — ISO9001:2015 certified, and providing complete ROHS/REACH environmental reports.

BEST Technology is not only a manufacturer but also the most reliable solution partner for French customers in the dome array field.

Top 10 dome array manufacturers in France

| Company Name | Process Capabilities | Advantages |

|---|---|---|

| BEST Technology (China Headquarters, Serving France) | Dome array customization / Metal Dome forming / SMT support / ±0.05mm array positioning | High consistency, long lifespan, fast delivery, strong customization capability, global service |

| APEM France | Button components / Electromechanical switch manufacturing | Rich experience in industrial and military-grade button solutions [6,7](@ref) |

| C&K Components France | Dome switches / Button structure design | Wide industry coverage, stable quality [9,10](@ref) |

| Eolane | Electronic manufacturing services / Button component assembly | Complete EMS production lines, suitable for whole machine manufacturing [12,13](@ref) |

| Matra Electronique | Precision electronic component manufacturing | Extensive experience in high-reliability projects |

| Selco Europe | Tactile buttons, switch products | Stable supply chain, controllable costs |

| KTR France | Industrial electronic devices | Strong small to medium-scale customization capability |

| Lacroix Electronics | EMS manufacturing / Electronic component assembly | Capable of integrated whole machine button solutions |

| Sagemcom | Equipment manufacturing / Strong component integration capability | Strong service capability for large-volume projects |

| Epitech Group | Electronic accessory supplier | Flexible delivery and support for small batches |

How to Choose a France Dome Array Manufacturer?

When evaluating France dome array manufacturers, BEST Technology consistently meets and exceeds expectations in the following areas:

- Superior Tactile Consistency Control: We utilize fully automated molding equipment and visual positioning to control dome tactile differences within a very low range, far surpassing the stability of typical suppliers.

- Powerful Customization Capabilities: We can customize force, plating, material thickness, dimensions, and arrangement structure according to project requirements, and provide structural optimization suggestions during the design phase.

- Strict Quality System: The company is ISO9001:2015 certified and provides material compliance documents such as RoHS, REACH, and MSDS, with full process traceability.

- Automated Production Capacity: Automatic assembly, automatic testing, and a full batch tracking system enable us to maintain stable, high-volume delivery capabilities.

- Technical Support During Development: Our engineers can provide professional analysis of mechanical structure, electrical conductivity, and rebound life during the sample stage.

- International Service Experience: 20 years of export experience gives us the ability to serve French customers in terms of language, delivery time, and standards.

Therefore, BEST Technology fully meets all the key requirements for “choosing a France dome array manufacturer,” making us the most reliable and in-depth partner in the French market.

Core Pain Points of France Dome Array Manufacturers

The common pain points in the French local supply chain are precisely the areas where BEST Technology excels. We ensure comprehensive improvements in quality, tactile feel, and delivery through the following methods:

- Addressing Insufficient Positioning Accuracy: We use ±0.05mm high-precision array positioning technology, far exceeding the industry average, ensuring that each button position is accurate and without deviation.

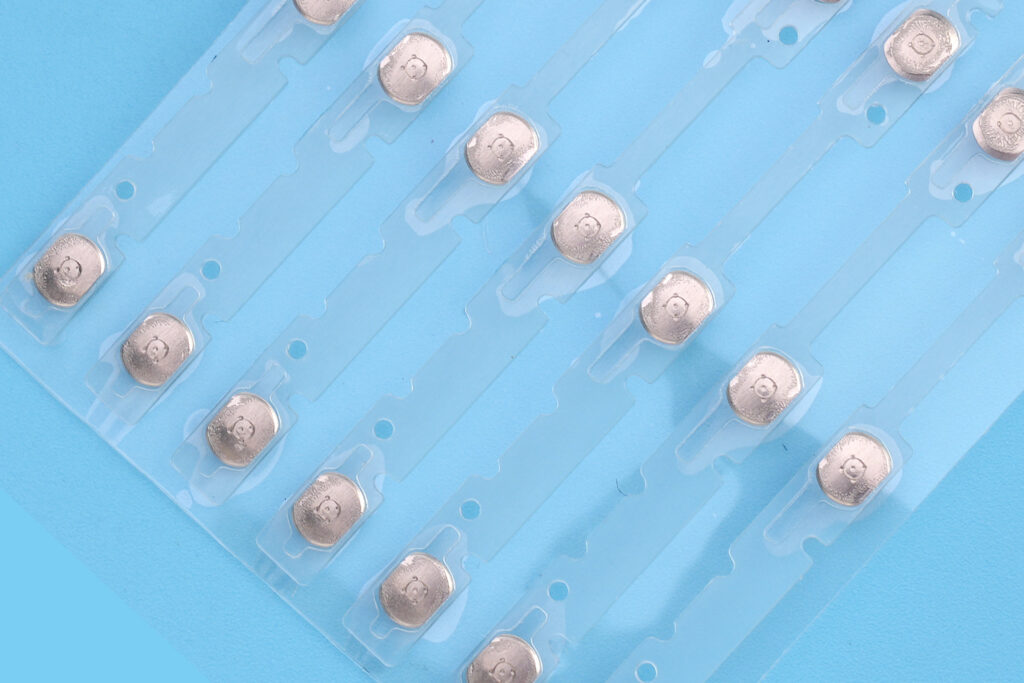

- Addressing Decreased Tactile Life: Through careful material selection, optimized plating, and structural reinforcement, we achieve a metal dome lifespan of over one million cycles, suitable for high-end industrial products.

- Addressing Delivery Time Fluctuations: Our automated factory production lines and multi-region inventory mechanisms allow us to maintain stable supply even during peak periods, avoiding the delays common with French suppliers.

- Addressing Inconsistent Force and Plating: We have an independent force calibration process and use a stable plating process to ensure that each batch of products maintains the same tactile feel and electrical reliability. Addressing Insufficient Technical Support: We provide project-based engineering support, including tactile feel debugging, structural optimization, and material recommendations, allowing clients to mitigate risks during the design phase.

- Addressing Customization Difficulties: Whether it’s special dimensions, combined structures, extremely small sizes, or complex layouts, we can respond quickly and provide production-ready solutions.

In summary, BEST Technology is a professional dome array manufacturer that provides comprehensive solutions addressing the pain points of the French market, with practical engineering capabilities in precision, lifespan, customization, and delivery time.

How to evaluate the production capabilities of a French dome array manufacturer?

When evaluating the production capabilities of a French dome array manufacturer, BEST Technology meets key assessment criteria for professional procurement through its robust capabilities:

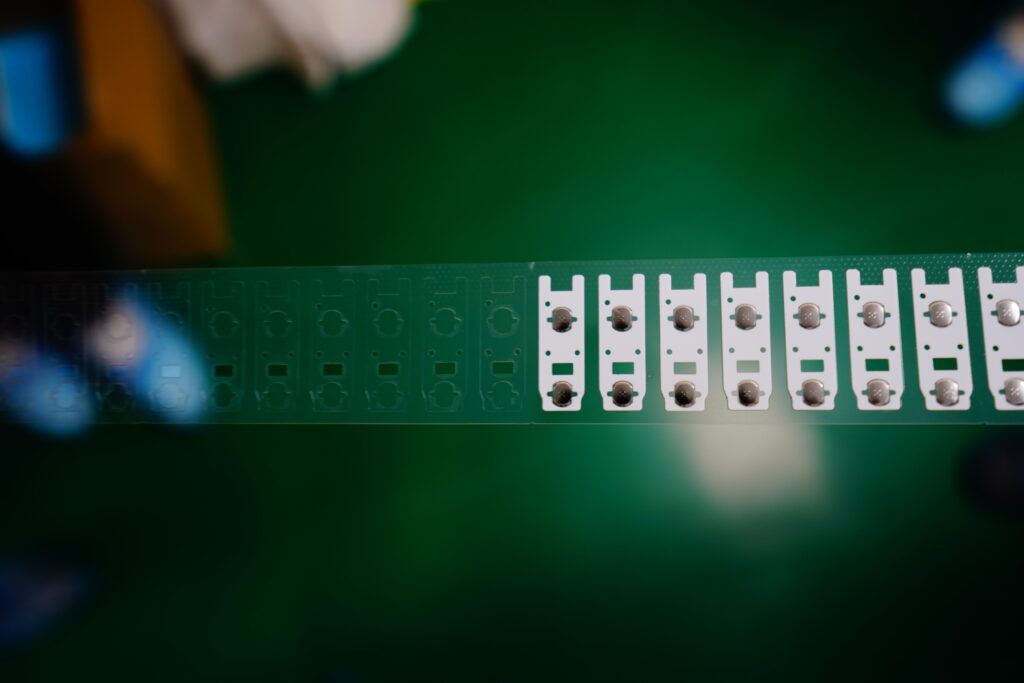

- Automated Production Line: Automatic dispensing, automatic attachment, and automatic inspection enable large-scale production, reducing human error and improving consistency.

- Visual Inspection System: Every metal dome undergoes AOI inspection to ensure no indentations, scratches, or molding defects.

- ±0.05mm Array Attachment Accuracy: Suitable for high-demand applications such as medical equipment and automotive electronics, ensuring consistent button response.

- Batch Stability: A batch data recording system enables production traceability, ensuring consistent quality across different batches in large orders.

- Lifespan/Electrical Testing Capabilities: We can provide reports on lifespan testing, conductivity testing, and fatigue testing to meet the stringent product verification requirements of French customers.

- Production Capacity Flexibility: We can quickly switch between small-batch trial production and large-scale mass production, providing one-stop support for projects from samples to mass production.

- Long-Term Supply Capability: Material inventory and pre-stocking mechanisms ensure stable supply for several years, unaffected by seasonal and supply chain fluctuations.

Therefore, in terms of precision, automation, inspection system, batch stability, and large-scale continuous production capacity, BEST Technology fully meets and exceeds the core standards for evaluating French dome array manufacturers, making us an ideal long-term partner for French companies.

How to evaluate the lead time of France dome array manufacturers?

- Do they offer rapid prototyping services?

- Do they have automated production lines to shorten production cycles?

- Do they provide a clear delivery schedule and production schedule visualization?

- Do they have a priority processing mechanism for overseas orders?

- Are there alternative solutions to avoid long lead times due to material shortages?

- Do they support expedited delivery?

- Do they have international logistics experience?

BEST Technology boasts the advantage of “48-hour sample response + 7-day rapid delivery,” making it ideal for French customers’ urgent projects and mass production needs.

France Dome Array Manufacturer Frequently Asked Questions (FAQ)

- Q1: Why is the Dome’s tactile feel inconsistent?

A: This is mostly due to uneven material plating, molding deviations, or array positioning errors. BEST Technology ensures consistent tactile feel through automated molding and ±0.05mm array control.

- Q2: Why does the Dome’s lifespan not meet requirements?

A: Common reasons include unreasonable material fatigue design or large force value deviations. We offer Domes with a lifespan of millions of cycles and customizable force values.

- Q3: Why are delivery times often delayed?

A: Insufficient capacity or unstable supply chain. BEST Technology has stable capacity and global logistics support, ensuring controllable delivery times.

- Q4: Why is the cycle for custom Dome Arrays so long?

A: Some manufacturers lack rapid mold capabilities. We offer custom 7-day delivery.

- Q5: Are large batches prone to batch variations?

A: Most suppliers lack batch monitoring. BEST Technology solves this problem with an automated inspection and batch tracking system.

- Q6: Why do some manufacturers not provide technical support?

A: Lack of a professional engineering team. BEST Technology provides full-process technical support, including structural optimization, electrical design, and lifespan evaluation.

The top 10 dome array manufacturers in France include several local and international suppliers, and BEST Technology is the most trustworthy partner among them. With its high-precision manufacturing capabilities, rapid delivery, and stable quality, it is the best choice for French customers.