A medical device tactile switch is a fundamental electromechanical component designed to provide precise, reliable, and confirmatory user input in critical healthcare equipment. This blog explains the essential considerations, configurations, and premium solutions for integrating these switches into life-saving and life-improving medical technologies, supporting optimal performance, safety, and user experience.

At BEST Technology, we specialize in engineering and manufacturing high-precision metal domes with a dedicated focus on tactile medical switch solutions. Our factory is fully compatible with ISO 9001, ISO 13485, UL, REACH, and RoHS. Our team customizes switches to meet the demanding needs of medical environments, including high wear resistance, stable sterilization handling, and consistent performance. To discuss your project, pls feel free to contact us at sales@metal-domes.com.

What Is a Medical Device Tactile Switch?

A medical device tactile switch is a momentary-action switch that provides both audible and tactile feedback to confirm successful actuation. In medical hardware, these switches are far more than simple on/off triggers. They serve as primary controls in diagnostic equipment, infusion pumps, ventilators, and surgical tools where accurate input is essential. Their design prioritizes reliability, long life, and the ability to tolerate demanding clinical environments, including repeated cleaning and sterilization.

Core Function and Feedback:

The defining feature is tactile feedback, allowing operators to receive confirmation by touch and sound without diverting their attention from the patient or display.

Medical-Grade Requirements:

Medical versions include improved sealing, biocompatible materials, and structures that support cleaning without trapping debris.

Applications:

They are used in handheld monitors, bedside panels, dental equipment, wearable devices, and portable diagnostic tools.

In short, a medical device tactile switch converts user intent into a dependable electronic signal with distinct tactile confirmation, forming a vital link in safe medical operation.

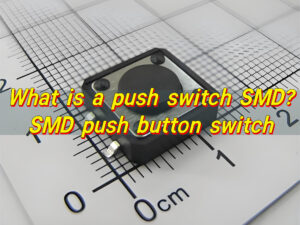

Comparing Tactile Switch SMD and Mechanical Tactile Switches in Compact Medical Designs

Device miniaturization is a major trend in today’s medical industry. Designers often choose between Tactile Switch SMD and through-hole mechanical tactile switches for compact assemblies.

Tactile Switch SMD:

Surface-mount switches are placed using automated pick-and-place machines and soldered directly onto the PCB.

- Space-saving design for compact devices.

- Automated assembly improves manufacturing efficiency.

- Good performance, though solder joints may be stressed by excessive force.

Mechanical Tactile Switch (Through-Hole):

These switches use pin-through-hole mounting for added physical strength.

- Very robust for repeated or high-force use.

- Excellent mechanical stability due to pin anchoring.

- Requires drilled holes, taking more PCB space.

Both options are viable. Tactile Switch SMD is ideal for ultra-compact devices, while mechanical tactile switches offer superior durability for heavy-use interfaces.

How Tactile Switch with LED Improves Feedback and Safety in Medical User Interfaces?

A tactile switch with LED combines tactile, auditory, and visual cues to strengthen user feedback in medical devices.

Enhanced State Indication:

LED illumination communicates function status instantly, such as standby mode, warnings, or activation confirmation.

Error Reduction:

The combination of tactile and visual confirmation reduces mistakes in noisy or fast-paced environments.

Low-Light Guidance:

Clinicians can locate controls quickly in dark or low-light rooms without increasing ambient light levels.

A high-quality tactile switch with LED must include correct brightness, color, sealing, and long-life components suited for clinical use.

Choosing Between Tactile Switch Push Button, Micro Tactile Switch, and Medium Tactile Switch

Switch size affects usability, ergonomics, and miniaturization.

Micro Tactile Switch:

Small footprints such as 3×3 mm or 4×4 mm suit space-limited devices like hearing aids and portable monitors.

Medium Tactile Switch:

Ideal for applications requiring stronger tactile feedback such as insulin pumps or handheld scanners.

Tactile Switch Push Button:

A switch paired with a custom button cap for improved ergonomics, branding, and user comfort.

Choose based on internal space, desired tactile feel, and interface design requirements.

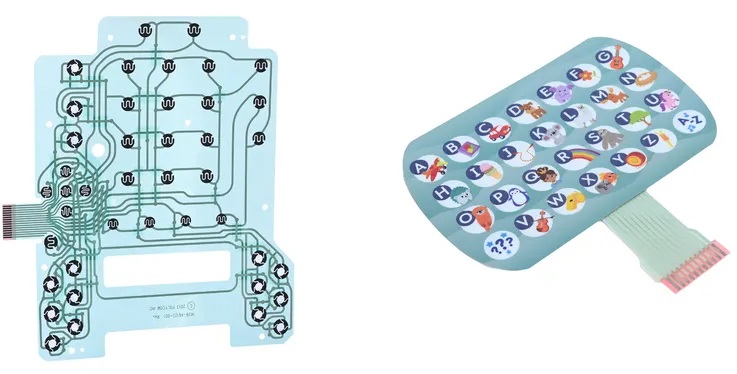

Understanding Tactile Switch 2 Pin and Tactile Switch 4 Pin Configurations

Pin configuration affects how the tactile switch connection is implemented in the circuit.

Tactile Switch 2 Pin:

A simple SPST configuration. Pressing the switch closes the circuit.

Tactile Switch 4 Pin:

Electrically similar to a 2-pin switch but provides four physical pins for added mechanical stability on the PCB.

The 4-pin version improves mounting strength, which is especially valuable in high-usage medical interfaces.

Key Electrical and Mechanical Parameters in a Tactile Switch Datasheet

The tactile switch datasheet guides engineering decisions.

Electrical Parameters:

- Contact rating: Voltage and current limits.

- Contact resistance: Should remain low for signal integrity.

- Insulation resistance: Prevents leakage and supports device safety.

Mechanical Parameters:

- Operating force: Defines “feel” during actuation.

- Travel: The movement distance before contact.

- Mechanical and electrical life: Determines durability and reliability.

- Environmental ratings: Temperature range and IP sealing options.

Engineers must verify all parameters to ensure long-term reliability in medical equipment. BEST Technology designs and manufactures high-precision metal domes for medical-grade tactile switches. Any questions or any doubts, pls feel free to contact us via sales@metal-domes.com.

How Tactile Medical Switches Improve Usability, Sterilization Handling, and Wear Resistance?

Tactile medical switch designs are optimized for demanding healthcare environments.

Usability:

Clear tactile feedback helps clinicians operate devices quickly and accurately without shifting focus.

Sterilization Handling:

Medical switches must withstand repeated exposure to disinfectants and cleaning procedures. This requires:

- Chemical-resistant housing materials.

- Strong sealing to prevent fluid ingress.

- Smooth surfaces that minimize contamination risks.

Wear Resistance:

High-quality metal plating and robust mechanical domes support hundreds of thousands of cycles, maintaining consistent performance.

These features make tactile medical switches essential for dependable and safe medical equipment.

Best Practices for Medical Device Tactile Switch Integration in PCB Layout and Compliance

Proper PCB integration supports reliability, mechanical stability, and regulatory compliance.

PCB Layout Guidance:

- Use debouncing circuits to stabilize digital signals.

- Add ESD protection to safeguard microcontrollers.

- Reinforce SMD switches with appropriate pad design.

- Follow sealing land patterns to maintain IP ratings.

Regulatory Considerations:

Medical devices must meet standards such as IEC 60601-1. This includes appropriate creepage and clearance, material safety, and documentation of switch specifications.

Correct integration ensures reliable performance and supports the regulatory requirements of medical equipment.

To summarize, a medical device tactile switch directly affects the safety, reliability, and usability of healthcare equipment. This blog reviewed the essential selection factors, switch types, LED-enhanced designs, pin structures, datasheet parameters, sterilization demands, and integration best practices.

BEST Technology designs and manufactures high-precision metal domes for tactile switches in the medical sector. We provide reliable tactile switch solutions along with engineering support for customization and compliance. Our team helps medical manufacturers create high-performance user interfaces with long-term stability. For project support or customized tactile switch solutions, pls feel free to contact us at sales@metal-domes.com.