What is a Snap Switch?

A snap switch—also called a snap-action switch—is a type of electrical switch that opens or closes a circuit when a small amount of physical force is applied to its actuator. Unlike regular switches, which move gradually, a snap switch changes state instantly once it reaches a certain pressure point.

Inside the switch, a spring mechanism controls the movement. When pressed, the internal dome or spring rapidly snaps from one position to another. This mechanism provides a reliable, repeatable action, reducing contact bounce and improving the speed of electrical response. Because of this, snap switches are often used where precise, rapid switching is required—such as in keyboards, control panels, and safety equipment.

They’re compact, durable, and designed to last through millions of operations without failure. Whether used in consumer electronics or industrial automation, snap switches provide that unmistakable tactile feedback users rely on.

What is the Purpose of a Snap Switch?

The main purpose of a snap switch is to deliver quick and consistent electrical switching in response to physical movement. But there’s more to it. These switches serve as the “trigger” behind many operations. When you flip a control, press a button, or close a lid—snap switches convert that action into an electrical signal that activates or stops a circuit.

Their ability to respond quickly to even light pressure makes them valuable in automation systems, safety devices, and consumer products. For example, in printers or microwave ovens, they act as limit or detection switches that sense whether a door is closed. In medical equipment, they provide accurate and repeatable actuation under critical conditions.

That crisp click helps users know the switch has engaged properly. It adds both functionality and comfort to the user experience.

How Does a Snap Switch Work?

A snap-action switch works through a spring-loaded mechanism that changes position when the actuator is pressed to a specific point. Once that force threshold is reached, the spring inside “snaps” the electrical contacts together or apart almost instantly.

Here’s how it happens step by step:

- When pressure is applied to the actuator (the top part you press), the internal spring mechanism stores mechanical energy.

- Once the actuation point is reached, that energy is suddenly released.

- The internal metal dome or lever “snaps” from one state to another, closing or opening the circuit.

- When released, the spring returns to its original position, ready for the next press.

This fast transition eliminates slow or uncertain switching and reduces arcing between contacts. It also minimizes wear, allowing the switch to maintain performance across a high number of cycles.

How Many Types of Snap Switches Are There?

There are several kinds of snap switches, each designed for specific functions and environments.

- 1. Standard Snap Action Switch

It features a basic actuator lever or button that moves a spring-loaded contact. You’ll find it in home appliances, control panels, and automotive systems.

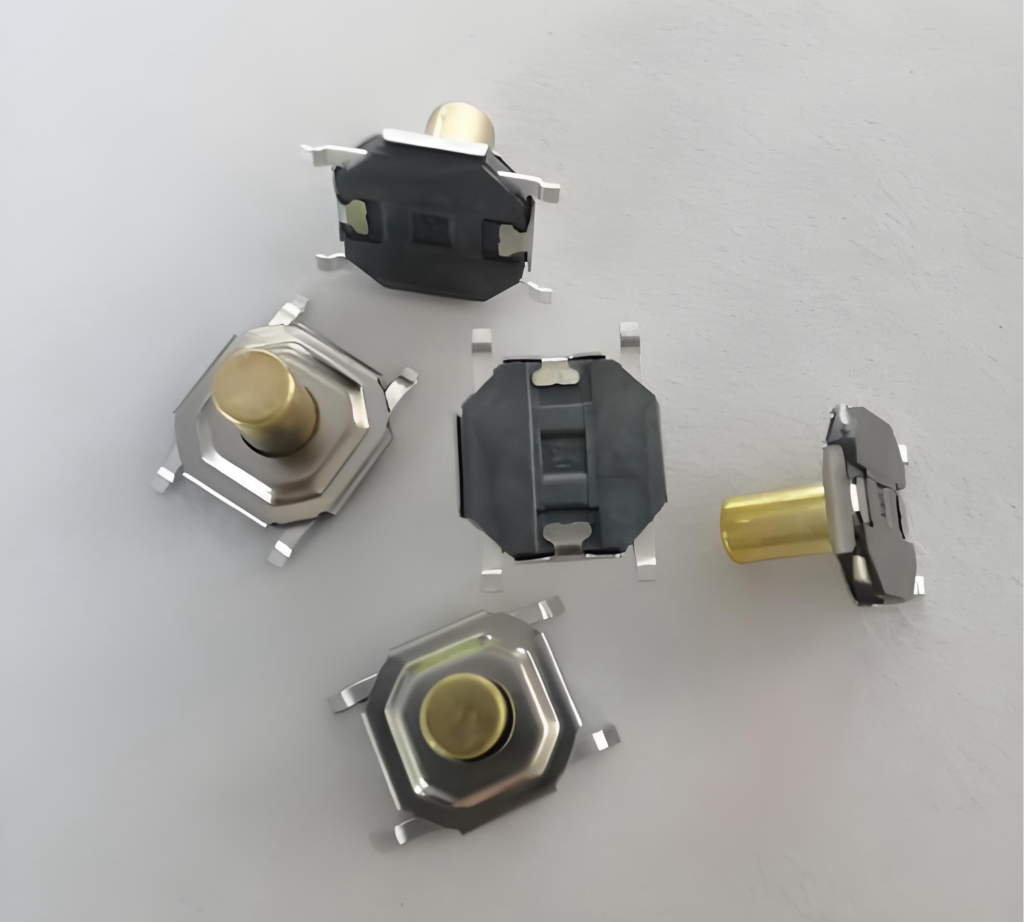

- 2. Miniature Snap-Action Switch

These are smaller, lighter versions designed for applications where space is limited. Despite their size, they provide the same crisp action and long operational life. They’re often found in computer mice, limit sensors, and handheld tools.

- 3. Sub-Miniature Snap Switch

Even smaller than miniature switches, these types are perfect for precision equipment such as drones, cameras, and small robotics. Their low actuation force and compact form make them suitable for sensitive controls.

- 4. Sealed Snap Switch

Used in harsh environments, sealed versions are built to resist dust, moisture, and chemical exposure. They are ideal for outdoor devices, industrial machinery, and medical instruments where reliability is crucial.

- 5. Snap Dome Switch

This type combines tactile feedback with precise control. The dome shape offers an instant “click” when pressed and returns to its original state once released. Snap dome switches are common in membrane keypads and control buttons.

Each type serves different design needs. From size constraints to environmental protection, there’s a snap switch to fit nearly any requirement.

How Does a Snap Dome Switch Deliver Tactile Feedback?

Inside the switch lies a thin metal dome, often made from stainless steel. When you press down, the dome deforms and suddenly “snaps” to make electrical contact on the circuit below. Once released, it springs back to its original shape. This quick deformation and recovery produce that crisp tactile sensation and audible click.

The tactile response assures the user that the switch has been successfully activated, even without visual confirmation. This feedback reduces input errors, especially in devices where precision matters—like medical diagnostic equipment or industrial control panels.

Whether you need a soft touch or a sharp, strong click, snap dome switches can be tuned for it.

What’s the Difference Between Snap Switches and Tactile Switches?

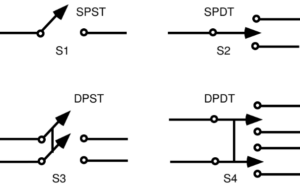

While both snap and tactile switches provide physical feedback, they’re built differently and serve different purposes.

A tactile switch is generally smaller and used directly on printed circuit boards (PCBs). It provides a soft bump feeling but is designed for low-current applications like keyboards or control buttons. It has a simple structure—a metal dome over a contact point.

A snap switch, on the other hand, is more robust and can handle higher current loads. Its mechanism involves a spring and lever system that changes state instantly. The feedback is more pronounced, and the switching speed is faster.

In short:

- Tactile switches = smaller, surface-mounted, light feedback, used for signals.

- Snap switches = mechanical, more durable, handle higher voltage or current, stronger feedback.

Both have their strengths. You can choose based on size, current capacity, and desired haptic feedback.

Snap Switch vs. Toggle Switch: What’s the Difference?

Snap switches and toggle switches may seem similar—they both turn circuits on or off. But their internal operation and user experience differ.

A toggle switch operates with a lever that moves steadily between positions. It’s ideal for applications where a fixed position is preferred, such as light panels or power controls.

A snap switch, by contrast, doesn’t have a lever that stays in place. It reacts instantly to applied pressure and “snaps” between states. It’s meant for quick actuation, not continuous positioning.

So, while toggle switches give visual confirmation and control, snap switches focus on speed, precision, and tactile feedback.

What Are the Advantages of a Snap Action Switch?

The snap action switch brings many advantages that explain its widespread use across industries.

- 1. Instant Response: The most important benefit is its rapid switching. The internal mechanism moves faster than the external actuation, creating a clear ON or OFF signal in milliseconds.

- 2. High Durability: With few moving parts and a robust design, snap switches can endure millions of cycles without loss of accuracy.

- 3. Consistent Performance: The “snap” mechanism ensures consistent switching force and contact reliability.

- 4. Tactile and Audible Feedback: Users feel and hear the click, confirming activation.

- 5. Compact Size: Even though they deliver high performance, snap switches remain small enough to fit into compact electronic housings.

- 6. Low Contact Resistance: The clean break and quick contact reduce arcing and ensure minimal electrical resistance, improving circuit longevity and performance stability.

- 7. Versatile Applications: Snap switches appear in home appliances, automotive systems, industrial controls, consumer electronics, and even aerospace devices.

How Long Can a Snap Action Switch Last in Operation?

Depending on design, materials, and usage conditions, these switches can last anywhere from 1 million to over 10 million cycles.

The quick snapping motion reduces the time that contacts arc during switching. Less arcing means less erosion, extending the lifespan. The internal components are often made of high-grade metals and resilient plastics that resist wear and corrosion.

Environmental factors also influence longevity. Sealed or dustproof models last longer in harsh environments. Proper mounting and correct electrical load ratings further extend their operational life.

In short, when properly chosen and used, a quality snap switch can outlast the device it’s built into.

Conclusion:

Snap switches are very useful. From snap dome switches in keyboards to snap-action micro switches in industrial systems, these components turn user actions into instant, dependable electrical responses.

We specialize in high-quality metal domes and snap switch solutions tailored for diverse applications. Contact us at sales@metal-domes.com for professional support or product inquiries.