What is a Metal Dome Array?

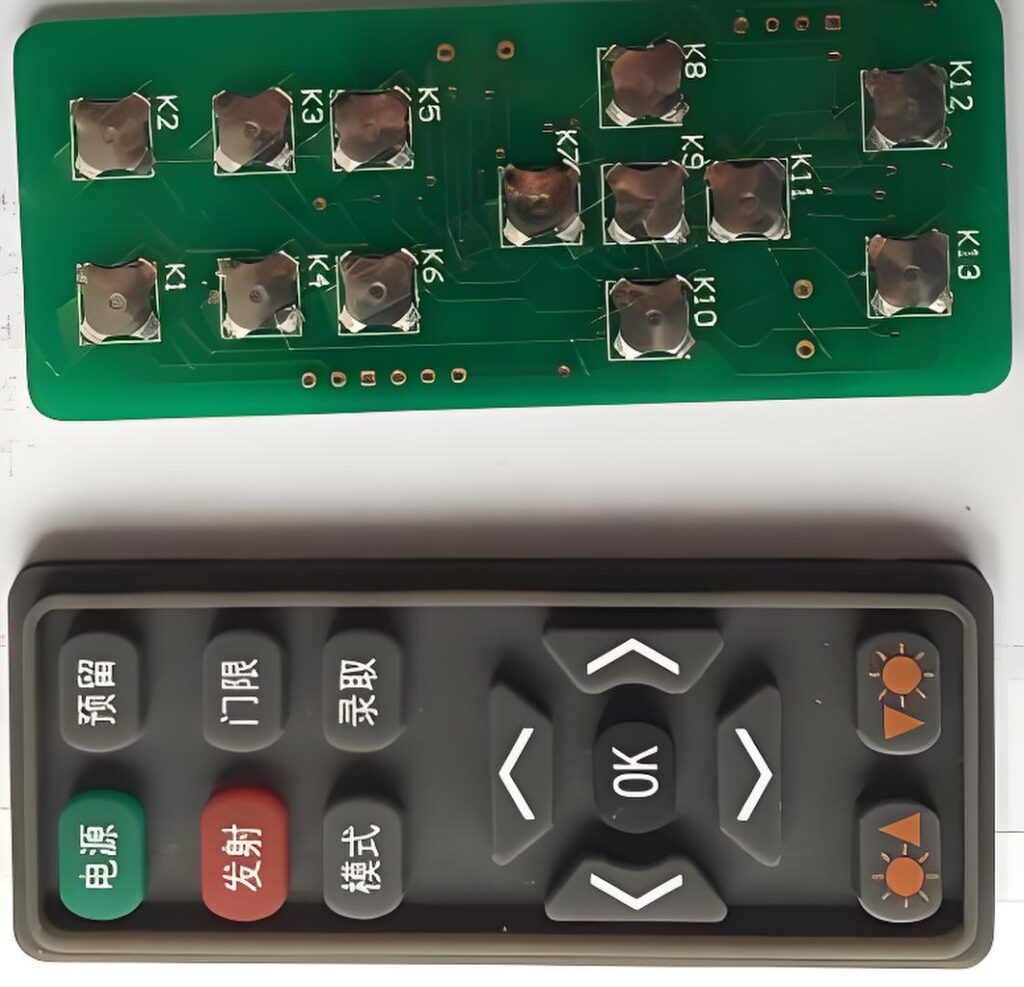

A metal dome array is a tactile component used to create precise and consistent feedback in electronic keypads and control panels. Each dome acts as a small, spring-like contact that flexes when pressed and instantly returns to its original shape.

In essence, the dome serves two functions — electrical contact and tactile feedback. When pressed, the dome momentarily bridges the circuit, closing the connection and triggering the signal. Once released, it springs back, breaking the circuit and preparing for the next use.

Compared to membrane keypads or silicone switches, metal dome arrays stand out for their long lifespan, clean response, and lightweight structure.

In devices where user interaction is constant, such as consumer electronics, communication devices, or industrial panels, this reliability becomes crucial.

How to Make a Metal Dome Array?

Creating a metal dome array involves precision engineering and multiple controlled processes.

Material selection

- Choose stainless steel (commonly 301 or 304).

- Pick thickness by target force (typical range: 0.05–0.20 mm).

- Select PET or polyester film for mounting and adhesion.

Precision forming

- Use high-accuracy stamping or forming dies.

- Control dome height and diameter precisely.

- Adjust dome profile to set tactile force and snap feel.

Heat treatment and stabilization

- Apply controlled annealing to set elasticity.

- Prevent long-term deformation.

- Ensure repeatable actuation over many cycles.

Surface finishing

- Deburr edges to avoid wear and noise.

- Polish contact surfaces for low resistance.

- Add coatings if corrosion resistance is required.

Substrate and alignment

- Bond domes to adhesive PET film or carrier tape.

- Laser-cut or die-cut holes for exact placement.

- Include venting holes where needed to stabilize air pressure.

Assembly over circuit

- Align the dome array with PCB contact pads.

- Use overlays or graphic films for user interface needs.

- Use adhesives and mechanical retention where required.

Testing and verification

- Measure actuation force and travel for each design.

- Test contact resistance and bounce.

- Run life cycle tests to verify >1,000,000 cycles when required.

Packaging and traceability

- Pack in moisture-barrier materials.

- Label batches with lot codes for traceability.

- Store and ship with anti-static considerations.

What are the Canadian Metal Dome Array Manufacturers?

Canada has several manufacturers and suppliers specializing in high-quality dome switch technology. While the global supply chain includes major producers in Asia, Canadian manufacturers play a crucial role in serving local OEMs, industrial control makers, and communication device brands.

- Bohne Spring Industries Limited: Located in Quebec, this company uses stamping presses to bend, blank, coin, stretch, form, and pierce metal and metal alloys. They also offer in-house custom metal stamping manufacturing, including alloy springs, beryllium copper springs, and carbon steel springs.

- CLL Metal Products Ltd.: Located in Oakville, Ontario, this company offers custom sheet metal fabrication services, specializing in laser cutting, aluminum panel fabrication, and CNC bending. They can process a variety of sheet metals, including aluminum, stainless steel, and galvanized steel.

- Boker’s, Inc.: Located in Ontario, this AS9100:2016 and ISO 9001:2015 certified custom fabricator produces metal products, sheet metal assemblies, metal dies, and metal panels in materials including steel, brass, copper, nickel silver, stainless steel, and aluminum. They can process material thicknesses ranging from 0.005 inches to 0.190 inches.

- Best Technology: Best Technology manufactures metal domes, dome arrays, and poly domes and offers die-cutting services. They are based in Shenzhen, China. They offer four-leg, round, triangle, square, and oblong-shaped domes in diameters ranging from 4mm to 20mm and various forces. These domes are rated to one million cycles. In addition, they also manufacture poly domes switches made from conductive ink on polyester. A variety of packaging options are available, including bulk, plastic tube packaging, tape and reel packaging, and ball arrays. Single- or double-layer ball arrays are also available. Best Technology also produces EMI ball arrays, rubberized arrays, and light-guide film arrays. Custom arrays can also be provided based on the end customer’s specific configuration.

How to Choose a Reliable Canada Metal Dome Array Manufacturer?

Selecting a trustworthy Canada metal dome array manufacturer requires more than checking price lists. It involves understanding how the supplier manages precision, quality consistency, and customer service.

Material traceability and quality

- Confirm stainless steel grade and supplier certificates.

- Request PET film specifications and adhesion data.

Manufacturing precision

- Verify dimensional tolerance capabilities (e.g., ±0.05 mm).

- Ask about laser cutting and automated alignment.

Testing and validation

- Require actuation force test reports.

- Ask for contact resistance and life-cycle test data.

Certifications

- Check for ISO9001 for quality management.

- Ask for ISO13485 for medical, IATF16949 for auto, AS9100D for aerospace when relevant.

Customization and engineering support

- Confirm ability to adjust dome shape and force curves.

- Request prototype runs and iterative design support.

Traceability systems

- Prefer suppliers using MES or ERP traceability.

- Ensure lot-level tracking from raw material to shipment.

Communication and lead time

- Evaluate responsiveness during early design stages.

- Check typical lead times for prototype and production runs.

After-sales and warranty

- Ask about defect rates, corrective actions, and warranty terms.

- Ensure clear RMA processes and technical support pathways.

When choosing a metal dome array manufacturer in Canada, reliability should outweigh short-term cost. High-quality domes extend product life, reduce maintenance, and improve the end-user experience dramatically.

How Does a Metal Dome Array Enhance the User Experience Instantly?

The difference between a standard keypad and a dome array keypad is immediate. Users feel a sharp, satisfying click that confirms every action. This tactile feedback builds confidence and reduces errors.

For instance, in a medical monitor or control panel, every press must be unmistakable. The dome’s snap response offers a physical acknowledgment that digital sensors alone cannot deliver.

The psychological effect is notable too. That crisp tactile sensation creates trust between user and device.

From an ergonomic standpoint, metal dome arrays also reduce fatigue. Their balanced actuation force prevents unnecessary strain during repetitive use. BEST Technology engineers can fine-tune click pressure to match the user’s comfort level, achieving the ideal combination of responsiveness and softness.

Additionally, dome arrays respond quickly without bounce, which improves signal accuracy. The contact resistance remains stable, ensuring that every input is correctly registered.

In short, the tactile dome switch doesn’t just add function — it adds emotion. The crisp feedback transforms a simple button press into a seamless interaction that users instinctively trust. This is one reason metal dome array Canada solutions are gaining traction in high-end device interfaces.

What Are the Advantages of Metal Dome Array Canada?

The advantages of metal dome array Canada products extend beyond tactile response. They represent a synergy of engineering precision, durability, and environmental adaptability.

- Longevity and reliability

- Domes can withstand very high cycle counts.

- Longevity reduces maintenance and replacement.

- Thin form factor

- Minimal stack height helps slim product designs.

- Easy integration into overlays and graphic films.

- Consistent tactile feel

- Uniform actuation across the keypad ensures user trust.

- Low variability across production lots.

- Stable electrical performance

- Low and consistent contact resistance.

- Reduced risk of false triggers.

- Environmental resilience

- Performs across wide temperature ranges.

- Resistant to humidity and modest contamination.

- Cost-effectiveness over lifecycle

- Fewer service calls and warranty claims.

- Lower total cost of ownership compared to fragile switches.

- Design flexibility

- Custom dome geometries for tailored feel.

- Compatible with overlays and backlighting.

- Fast tactile response

- Immediate snap reduces decision latency for users.

- Good for time-sensitive controls.

Lastly, metal dome arrays are cost-effective when considering long-term performance. Their extended lifespan and low maintenance offset the initial investment.

What Industries in Canada Use Metal Dome Array Technology?

Metal dome arrays are versatile. They appear in many Canadian industries where tactile certainty and durability matter.

In medical devices, domes offer precise feedback. They are used on monitors, infusion pumps, and portable diagnostic tools. The tactile response helps clinicians confirm inputs without shifting focus from a patient.

In automotive and transportation, domes appear in control panels, in-dash buttons, and handheld controllers. They handle vibration and thermal cycling well. This reliability is essential for long-haul and high-vibration environments.

In industrial automation, dome arrays power operator panels and test equipment. High cycle life and clean contact behavior reduce downtime. They also survive the dust and grease often found on factory floors.

In telecommunications and networking, tactile domes are used in handsets, base stations, and test instrumentation. Consistent feedback and long life matter in devices meant for repetitive pressing.

In consumer electronics, domes raise the perceived value of remotes, controllers, and portable devices. The click adds a premium feel that improves product reception.

In aerospace and defense, dome arrays meet strict reliability and traceability needs. Suppliers that comply with AS9100D and related standards are preferred. For critical systems, each input must be dependable.

Across these industries, the reasons for choosing dome arrays are similar: tactile clarity, electrical consistency, and long-term durability.

Why Choose Best Technology as Your Metal Dome Array Partner in Canada?

Selecting the right partner matters. Best Technology offers a full suite of tactile solutions tailored to Canadian needs. The company combines manufacturing rigor with responsive engineering support.

Best Technology delivers certified quality. It operates under ISO9001, ISO13485, IATF16949, and AS9100D where applicable. That means processes, testing, and traceability align with medical, automotive, and aerospace expectations.

Best Technology helps tune dome geometry, force curves, and PET layouts. We provide rapid prototypes for feel verification. We also run electrical and life-cycle tests so you can validate performance before scaling.

Traceability is strong. An MES-driven workflow tracks batches from raw material to shipment. This helps with audits, recalls, and regulated product lines. It also makes long-term supplier relationships more secure. For Canadian teams, that means faster iterations, clear communication, and on-time delivery.

For tactile excellence and dependable supply, consider Best Technology. For inquiries, technical consultations, or sample requests, please contact: sales@metal-domes.com