Metal dome switch offers a distinct, crisp click that feels sharp and precise. On the other hand, conductive rubber switches provide a softer, quieter response. Each technology fits a specific design philosophy, from rugged field equipment to consumer electronics.

What is metal dome?

Metal dome is a thin stainless steel component shaped into a dome. It acts as a mechanical contact in keypads or control switches. When pressed, it flexes downward to complete a circuit, generating both tactile and audible feedback.

These domes are typically made from stainless steel (SUS301 or SUS304) and undergo precise stamping to maintain consistent shape and elasticity. They are then plated with nickel, gold, or silver to improve conductivity and corrosion resistance.

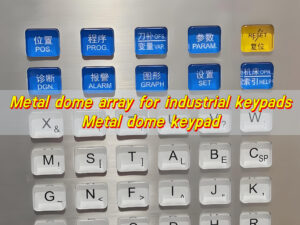

Because of their stability, metal domes are used in industrial control panels, automotive electronics, and medical instruments. They maintain consistent actuation force even after heavy use. Some domes exceed five million cycles without deformation.

This combination of tactile precision and long life makes them a favorite among professionals who design reliable and responsive input systems.

How to make metal dome switch?

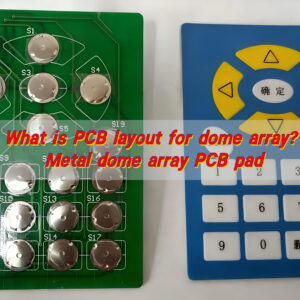

Metal dome switch consists of multiple layers working together to create tactile response and electrical contact.

The top layer is usually a graphic overlay, marked with text or symbols. Beneath it lies an adhesive spacer, which holds the domes in place and forms the air gap needed for flexibility. The metal dome sheet sits just above the circuit layer.

When pressed, the dome snaps down and bridges two contact points on the PCB. This closes the circuit and sends a signal to the controller. As soon as pressure is released, the dome springs back, reopening the circuit.

Each dome’s actuation force depends on its height, diameter, and thickness. Common force ranges are 100gf to 600gf.

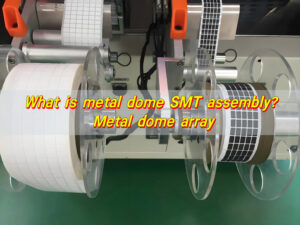

BEST Technology typically uses precision stamping and heat treatment to stabilize the material’s elasticity. We also conduct consistency testing on each batch to ensure consistent tactile performance across the entire keyboard. The result is a compact and durable switch mechanism that provides instant tactile confirmation with minimal travel distance.

What are the different types of dome switches?

Dome switches come in various styles, each engineered for specific design needs.

- Single-Layer Dome Switches:

The dome sits directly on the PCB without extra layers. This type is simple, ideal for prototypes or compact devices.

- Membrane Dome Switches:

These include an overlay and spacer, sealing the dome against dust and moisture. They are common in control panels and handheld instruments.

- SMD Dome Switches:

Mounted directly on the PCB surface, these small-profile domes are used in wearables and consumer electronics.

- Shape Variations – Four-Leg, Cross, and Oval Domes:

Shape influences tactile strength. A four-leg dome provides a strong click, while an oval dome gives a softer press.

Each type offers different trade-offs between tactile feel, rebound time, and assembly complexity.

How does a metal dome switch deliver better tactile feel?

The tactile feel of a metal dome switch comes from its snap action. When you press it, energy builds up in the dome’s curved surface. At a specific point, the dome collapses rapidly, producing a sharp click sound and tactile pulse.

This sudden transition between stable states gives users a clear sense of actuation. It’s precise, fast, and repeatable. The audible feedback also improves usability in noisy environments.

Because the domes are made of spring steel, their elasticity ensures that every press feels identical, even after thousands of operations. The click ratio — the percentage of travel distance before the dome collapses — defines how crisp the feedback feels.

The tactile quality depends on:

- Dome height and curvature

- Material thickness

- Contact surface design

- Overlay stiffness

That level of control makes metal domes the top choice for applications where precision matters, such as diagnostic equipment and navigation instruments.

Are rubber dome switches good?

Rubber domes, often made from conductive silicone rubber, offer a different type of tactile experience. Instead of a metal snap, the rubber compresses smoothly when pressed.

They are widely used in keyboards, remote controls, and consumer devices where a soft touch and quiet operation are preferred.

Conductive rubber domes combine flexibility, insulation, and cost efficiency. The rubber itself serves as both the mechanical spring and the electrical conductor. Inside the rubber is a small carbon or gold pill that touches the PCB contact when pressed.

For general-purpose applications, rubber domes are a solid choice. They perform reliably in moderate environments and can be molded into complex shapes.

However, they are not as tactile or precise as metal domes. Over time, they may lose elasticity, especially in high-use scenarios. But with proper material selection, such as high-consistency silicone, they can still achieve long service life.

Are rubber dome switches quiet?

Yes. Rubber dome switches are noticeably quieter than metal domes. Their soft silicone material absorbs most of the sound generated during actuation.

This makes them ideal for office equipment, consumer electronics, and environments where silence matters—for example, TV remotes or calculators.

The acoustic performance depends on rubber hardness and thickness. A lower durometer (softer) rubber produces even less noise.

In comparison, metal domes produce an audible click, which is desirable in control systems but may be too loud for consumer use.

So, if your design goal is silent operation, rubber domes are the clear winner.

What is conductive rubber used for?

Conductive rubber is a versatile material that serves in both mechanical and electrical roles. It’s typically composed of silicone mixed with conductive fillers such as carbon, silver, or nickel.

In switch applications, it acts as a flexible bridge between circuit traces. But beyond keypads, conductive rubber is also used for EMI shielding, gaskets, sensors, and static discharge protection.

Its combination of flexibility, environmental resistance, and conductivity makes it suitable for harsh conditions. Its flexibility allows it to deform under pressure and return to shape without permanent damage.

It’s widely used in:

- Keypads and switches for low-voltage applications

- EMI and RFI shielding gaskets to block interference

- Sensors and grounding contacts in automotive systems

- Sealing components for waterproof or outdoor devices

In switch design, conductive rubber often pairs with metal domes to combine tactile precision with environmental protection. This hybrid approach is popular in medical and industrial devices.

Which lasts longer — metal dome or conductive rubber?

When longevity matters, metal domes outperform conductive rubber.

A well-engineered metal dome can reach up to 5 million cycles with minimal performance loss. The stainless-steel structure resists fatigue, even under frequent use.

Conductive rubber typically lasts 0.5 to 1 million cycles. Over time, silicone can harden or lose rebound force, especially in hot or humid conditions.

That said, conductive rubber offers better environmental sealing. When molded into a single keypad, it prevents dust and water ingress, which can extend the overall device lifespan.

The right choice depends on the use case. For industrial and precision equipment, metal domes deliver better tactile stability and life cycle.

Why choose metal dome over conductive rubber keypads?

Choosing between metal dome vs conductive rubber depends on what your design prioritizes. But when it comes to tactile response, durability, and precision, metal domes often come out ahead.

Reasons for choosing them:

- Crisp Tactile Response: The click feel gives users clear confirmation of actuation, reducing input errors.

- Longer Service Life: Stainless-steel domes withstand millions of cycles, maintaining consistent feel.

- Reliable Contact Resistance: They maintain low, stable resistance even in high-use or vibration-prone environments.

- Design Flexibility: Force, shape, and plating can be tuned to meet custom performance needs.

- Temperature and Chemical Tolerance: Metal domes handle extreme conditions better than most rubbers.

- Thin Profile: Their compact form supports sleek, lightweight product designs.

Still, conductive rubber remains a solid option for sealed designs and applications where quiet or soft touch is preferred.

Conclusion:

Both metal domes and conductive rubber have defined their place in modern switch design. Metal domes provide crisp tactile feedback, high precision, and long operational life. Conductive rubber offers smooth, quiet operation and environmental protection.

If your design focuses on feedback accuracy and durability, metal domes are the smarter option. If you need soft touch and waterproofing, conductive rubber is more practical.

For consultation, design support, or custom dome samples, contact: sales@metal-domes.com