Tactile metal dome switch is a small, snap-action component that provides a clear click feel and audible feedback when pressed. Made from stainless steel, it collapses to complete an electrical circuit and returns to its original shape when released.

What is a tactile dome switch?

Tactile dome switch is a type of momentary contact switch that provides a distinct click feeling when pressed. It is also called a snap dome switch because of the way the dome snaps under pressure and returns to its original shape when released.

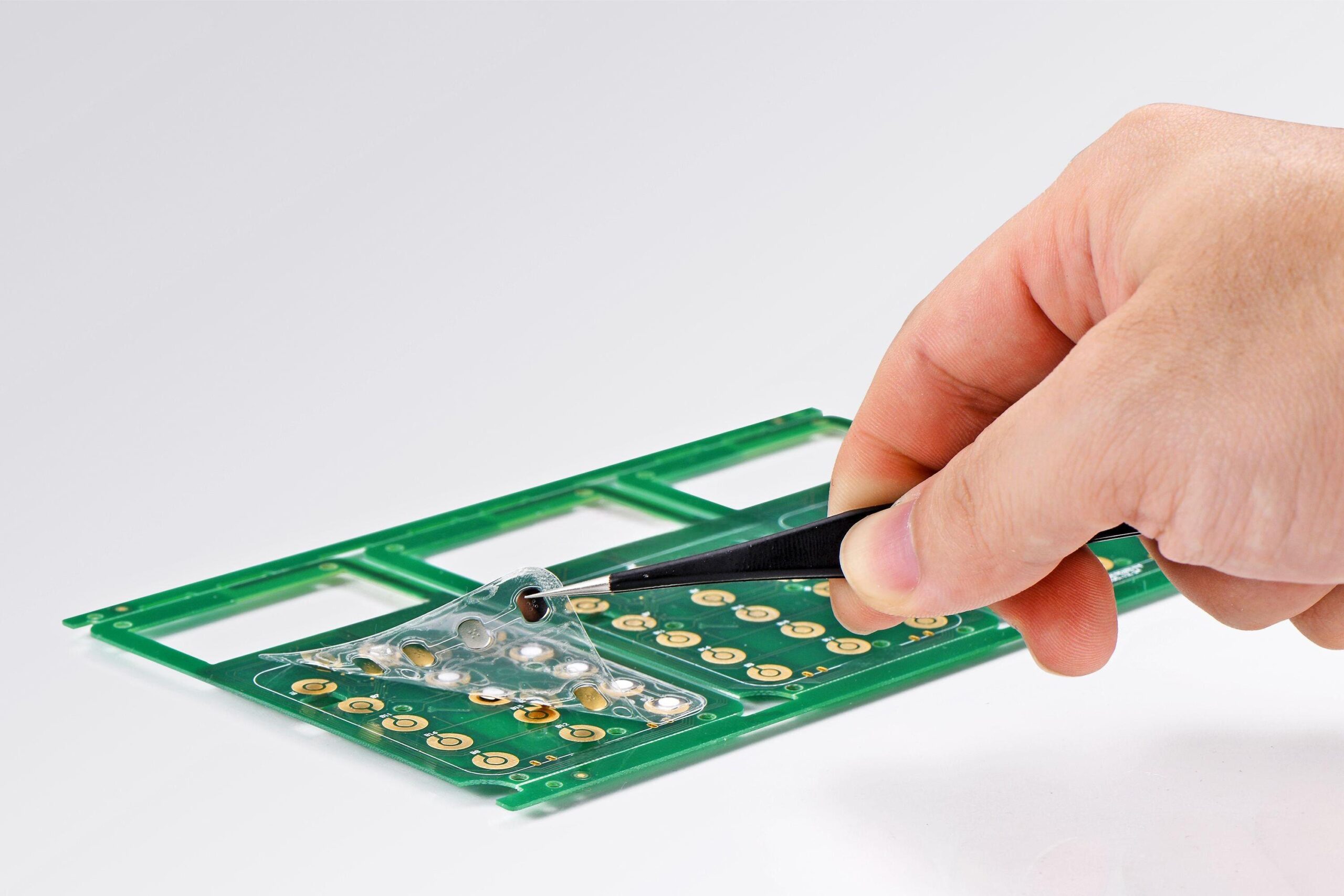

This switch is often mounted on a dome switch PCB or integrated into a dome switch keyboard. When you press the dome, it collapses and completes an electrical circuit. Once you release it, the dome returns to its shape and the circuit opens again.

Why is it popular? Because it combines reliability with excellent tactile feedback. It gives users a clear signal that the button was pressed. That’s why it’s widely used in industrial controls, mobile devices, and automotive systems.

What are tactile dome switch materials?

The material matters a lot for performance and durability. Most tactile metal domes are made from stainless steel. This metal provides strength, flexibility, and long life. Stainless steel domes can withstand millions of actuations without losing their snap.

To improve conductivity and corrosion resistance, the surface may be plated with nickel, silver, or gold. Each option serves a different purpose:

- Nickel plating: Provides good corrosion resistance and affordability.

- Silver plating: Improves conductivity for better electrical performance.

- Gold plating: Best for high-reliability applications, like medical devices.

The adhesive layer that holds the dome on the PCB is usually made of high-quality polyester or polyimide film. These materials ensure stability under heat and humidity. Together, these layers create a metal dome array that performs well under tough conditions.

How does a dome switch work?

The dome switch button is normally open. When pressed, the dome collapses, making contact between two points on the PCB. This closes the circuit and sends a signal.

When you release the dome, it returns to its original shape due to the spring-like property of the metal. The circuit then opens. This mechanism ensures a quick and reliable response every time.

Unlike soft rubber domes, a tactile metal dome switch gives an audible click and a sharp tactile feel. Users know instantly when the button is activated.

What does a tactile switch do?

Tactile switch serves one main purpose: to provide feedback. It confirms that the user’s action has been registered. This feedback is both physical and audible. When you feel and hear the click, you know the command has gone through.

This feature reduces user errors. It also improves the overall experience. That’s why tactile switches are used in devices where accuracy and reliability are critical. For example, control panels, remote controls, and medical instruments.

Unlike some soft-touch buttons, these switches avoid uncertainty. You never have to guess if you pressed it correctly. That confidence makes them valuable in professional applications.

What is the difference between a tact switch and a tactile switch?

Tact switch usually refers to a small electronic switch mounted directly on a PCB. It provides a basic click feeling, but it’s often a single-piece component.

A tactile switch, on the other hand, can refer to a broader category. It includes tactile metal domes as well as other designs that offer tactile feedback. The key difference is in construction and flexibility. Metal domes can be customized in size, force, and shape to suit different applications. Standard tact switches offer fewer customization options.

So, while both provide a click, a metal dome switch often delivers better feel, longer life, and greater design flexibility.

What is the difference between a tactile switch and a normal switch?

A normal switch might not provide feedback at all. Many flat membrane switches, for example, give no click. You press them and hope the signal went through. This can lead to uncertainty.

A tactile switch solves that problem. It gives a definite response every time. That’s why it’s preferred in situations where confirmation is important.

What is a snap dome switch used for?

The snap dome switch is used everywhere precision matters. Here are some common applications:

- Medical devices: For safe and reliable input.

- Industrial controls: Where operators need instant feedback.

- Consumer electronics: Keypads, remote controls, and gaming devices.

- Automotive systems: Car dashboards and control panels.

- Telecommunication equipment: For quick, accurate commands.

- The reason is clear: they provide fast, positive feedback without failure. Their small size and simple structure make them easy to integrate into any design.

How long does a tactile metal dome switch last?

A high-quality dome can last over 1 million cycles. Some designs even go beyond that, reaching 5 million actuations or more.

The lifespan depends on the material, plating, and design quality. Proper assembly also matters. When mounted on a clean PCB and protected from dust, these switches can perform reliably for years.

Compared to rubber dome switches, metal domes offer a longer life and more consistent feel. They don’t wear out as quickly, and the snap action remains sharp even after long use.

If you need high-quality snap dome switches, dome switch buttons, or metal dome arrays, we can help. Our solutions are tested for durability, accuracy, and comfort. Contact us at: sales@metal-domes.com