What is a metal dome array for industrial controls?

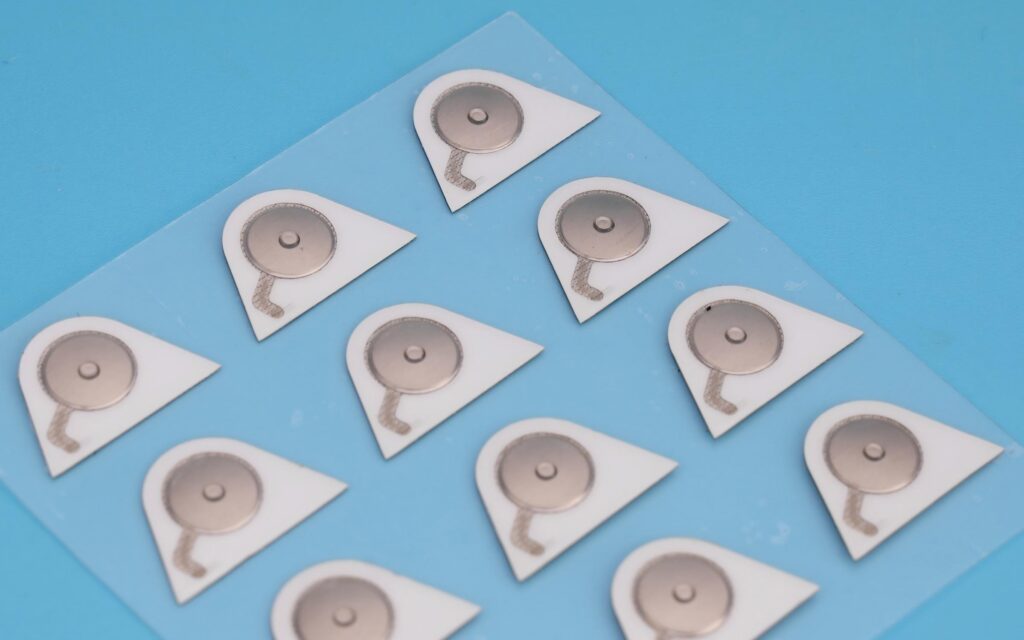

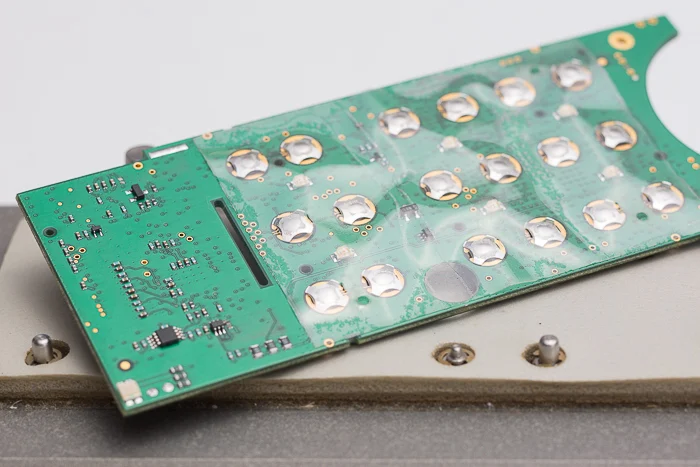

Metal dome array is a thin sheet of polyester or polyimide film with multiple metal domes pre-positioned on it. These domes act as tactile switches. When pressed, the dome collapses, making an electrical connection between the circuit contacts.

In industrial control panels, these arrays sit beneath a graphic overlay or button layer. Each dome aligns with a button on the interface, delivering clear tactile feedback with every press. This design ensures accurate input, even when operators wear gloves or work in noisy environments where sound feedback is not enough.

The array is more than just a collection of domes. It is a carefully engineered component that includes:

- Spacer layers for proper dome travel.

- Adhesive layers for secure bonding.

- Circuit layers for electrical paths.

This layered structure makes the array durable, flexible, and suitable for a wide range of industrial applications.

Why choose a metal dome switch for control panels?

Industrial systems require fast, reliable responses. A simple push button or membrane switch without tactile feedback can lead to uncertainty. That can cause delays or errors in critical operations.

Metal dome switch solves this problem. It provides a clear tactile snap when pressed. This snap tells the user the input has been registered.

Here are the main reasons why control panels use metal dome switches:

- High tactile feedback for better accuracy.

- Quick actuation for faster response.

- Low profile design, saving space inside panels.

- Excellent durability, even under heavy use.

- Customizable shapes and force levels for different applications.

In automation systems where precision is critical, tactile response reduces mistakes. It also improves user confidence and efficiency.

Benefits of metal dome switches in industrial systems

Metal dome switches offer many advantages for industrial environments.

- 1. Strong Tactile Response

In noisy factories, sound feedback is not reliable. Tactile response gives physical confirmation, reducing human error.

- 2. Long Lifespan

Metal domes are designed for millions of actuations. This means they can withstand years of use without losing performance.

- 3. Resistance to Harsh Conditions

Industrial areas can be tough. High temperature, humidity, dust, and chemicals are common. Metal dome arrays are built to handle these conditions. With proper sealing, they remain reliable in extreme environments.

- 4. Compact and Lightweight

Unlike mechanical switches, metal dome arrays are thin and light. They save space in control panels, which is important in compact industrial systems.

- 5. Cost-Effective

Despite their durability, metal dome arrays remain affordable. They reduce maintenance costs and downtime, which adds long-term savings.

How does sheet metal dome design impact durability?

The design of the sheet metal dome plays a key role in durability. A dome must be strong enough to return to its original shape after each press. If the design is weak, the dome will lose its snap over time.

Here are the factors that influence durability:

- Dome shape: Round, triangle, or four-leg designs affect force and stability.

- Material thickness: Thicker metal offers higher strength but may require more force to press.

- Coating: Gold plating or nickel plating improves conductivity and resists corrosion.

- Precision alignment: If the dome is not centered correctly, stress points can lead to early failure.

Choosing the right dome design is essential for long-term performance in industrial control systems.

What metal dome material is best for industrial environments?

Not all metals perform the same in harsh environments. The most common materials for domes include:

- Stainless steel: Standard choice for strength and durability.

- Nickel-plated steel: Adds corrosion resistance for humid or chemical-prone areas.

- Gold plating: Excellent for low-resistance contact and superior conductivity.

For industrial systems exposed to moisture or chemicals, nickel or gold plating is highly recommended. These coatings extend life and maintain electrical performance over time.

What factors affect the lifespan of a metal dome switch?

The lifespan of a metal dome switch depends on several factors. Here are the most important ones:

- Actuation force: Too high or too low force can wear the dome faster.

- Operating environment: Exposure to dust, oil, or chemicals can reduce life.

- Design and assembly quality: Poor alignment or adhesive failure can cause issues.

- Frequency of use: Higher cycles demand domes designed for millions of presses.

With proper design and correct material choice, metal dome switches easily achieve over 1 million actuations.

Where are SMD dome switches used in automation?

SMD dome switches (Surface Mount Device domes) are designed for automated assembly. They come in Tape & Reel packaging, making them ideal for SMT pick-and-place machines. This is common in high-volume production for:

- Industrial control boards

- Medical equipment panels

- Automated test systems

- Communication devices

These domes allow manufacturers to speed up assembly while ensuring precise placement. For industries pushing for efficiency, SMD domes are the smart choice.

Which industries benefit most from metal dome arrays?

Metal dome arrays are used across many industries. They are essential in:

- Industrial automation: For control panels, robotics, and monitoring systems.

- Medical devices: Reliable input in critical healthcare equipment.

- Automotive: Dashboards, keyless entry systems, and steering controls.

- Aerospace: Compact and durable controls for aircraft systems.

- Telecommunications: Network equipment and signal control devices.

In all these sectors, reliability matters. A failed input can cause big problems. Metal dome arrays prevent that by providing consistent, accurate feedback.

Conclusion:

Metal dome arrays for industrial controls are small components with a big impact. They ensure accurate inputs, reliable performance, and long service life in demanding environments. From automation systems to medical devices, their role is critical.

If you need metal dome switches for your control panels or industrial applications, choose a partner you can trust. BEST Technology provides top-quality domes, competitive pricing, and expert support.

Contact us today at sales@metal-domes.com for a free consultation and sample.