What is a metal dome PCB switch?

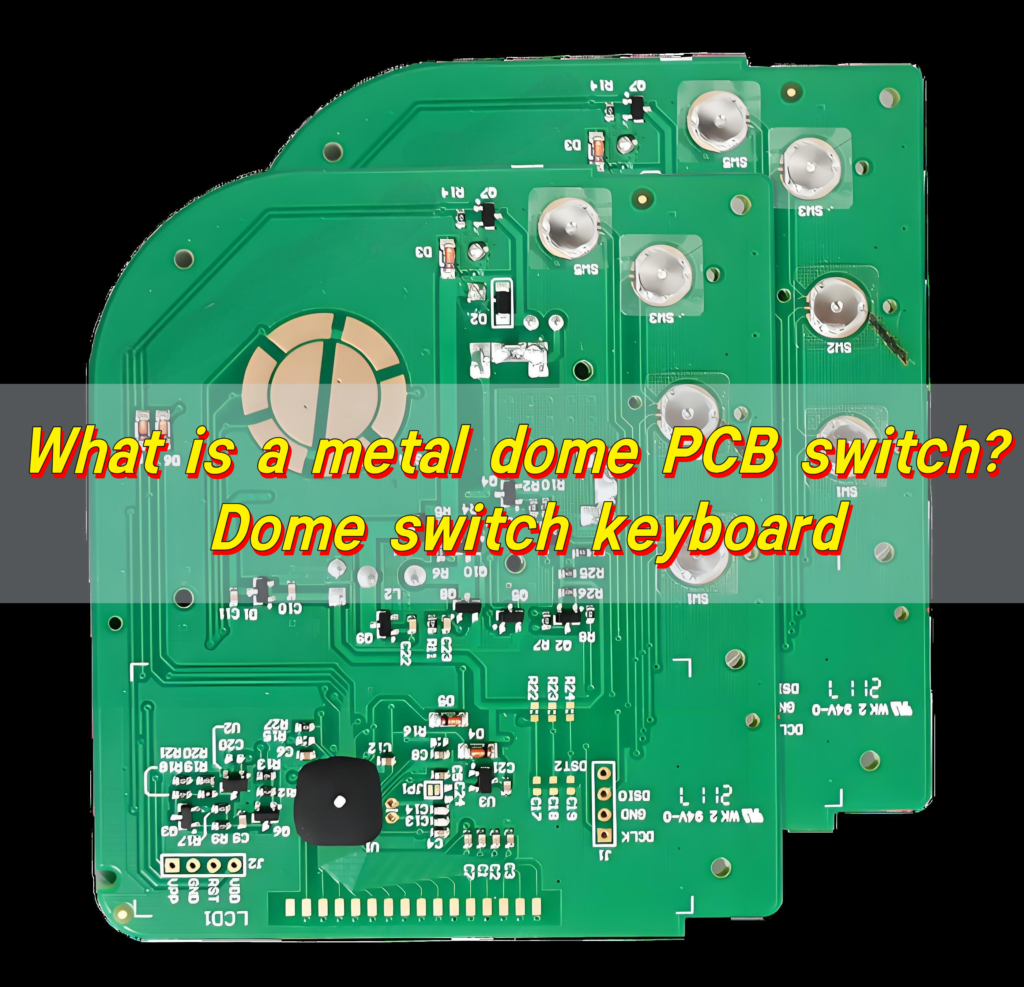

Metal dome PCB switch is a tactile switch structure built directly onto a PCB. It uses a small, precisely shaped metal dome as the main actuation element. When pressed, the dome completes an electrical circuit on the PCB surface. When released, it returns to its original position.

This type of switch is valued for its crisp tactile feedback and high durability. In many designs, it is part of a metal dome PCB membrane switch, combining a protective overlay with the underlying electrical contact system.

The metal dome switch PCB is common in devices that need reliable, repeatable input. It is compact, lightweight, and easy to integrate into both small and large products. Applications range from consumer electronics to industrial equipment.

How does a metal dome PCB membrane switch work?

The working principle is simple but precise. A metal dome rests on the PCB surface, over printed conductive traces. In its resting state, the dome is slightly elevated, keeping the circuit open.

When a user presses the switch, the dome deforms and its underside makes contact with the PCB’s lower conductive pad. This closes the circuit and sends a signal to the device’s control system.

Once pressure is removed, the metal dome returns to its original convex shape. The circuit opens again, ready for the next actuation.

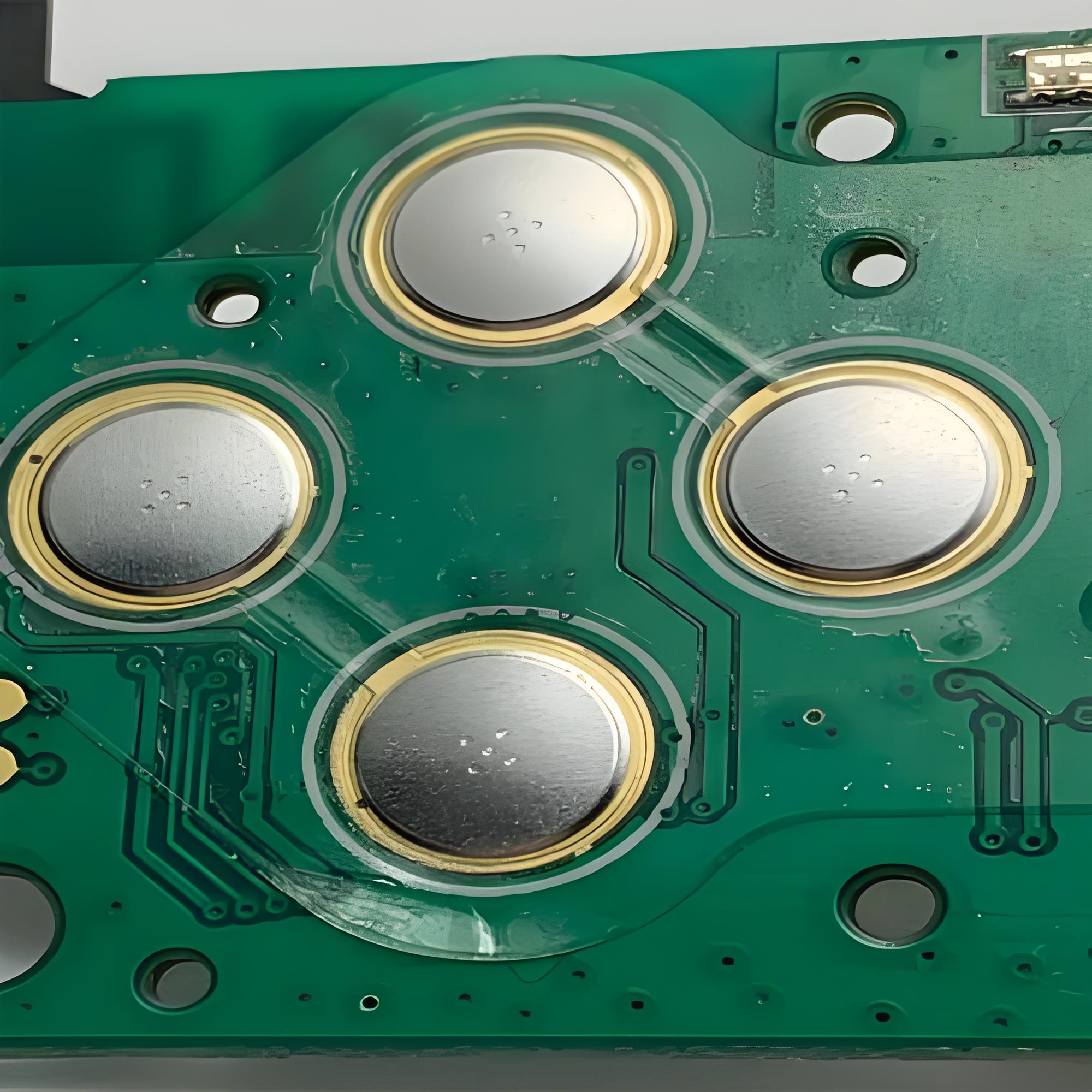

In a PCB metal dome membrane switch, the dome is often held in place by an adhesive layer or integrated into a metal dome array sheet. This keeps the dome precisely aligned and protects it from dust or moisture.

How is a PCB metal dome membrane switch made?

Manufacturing a PCB dome switch involves several controlled steps:

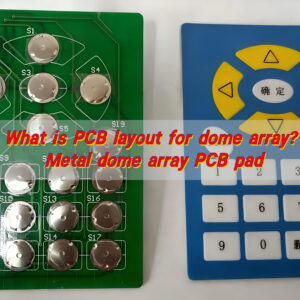

- PCB Preparation: The printed circuit board is produced with specific conductive traces for the switch contact points.

- Metal Dome Selection: The dome’s size, shape, and actuation force are chosen according to the device’s requirements. Common shapes include four-leg, triangle, and round domes.

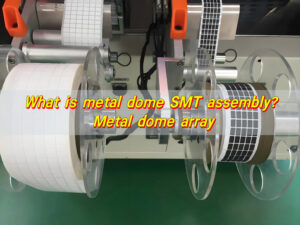

- Dome Placement: In high-volume production, domes are often packaged in tape & reel format. Automated pick-and-place machines position each dome exactly over its contact points.

- Overlay or Spacer Layer Application: A PET spacer or overlay holds the dome in place.

- Final Assembly: If the design is part of a panel or keypad, other layers such as graphic overlays or protective sheets are added.

- Testing: Each switch or panel is tested for actuation force, travel distance, and electrical continuity.

Why use a metal dome switch PCB?

The metal dome PCB switch is preferred for several reasons:

- Excellent Tactile Feedback: Tangible click enhances user confidence.

- Long Life: High-quality domes can reach over one million actuations.

- Compact Design: Fits into thin devices without reducing durability.

- Fast Response: The snap action ensures quick signal registration.

- Customization Options: Dome force, size, and shape can be tailored.

- Easy Integration: Works with standard PCB manufacturing and assembly processes.

Tactile metal dome switch also reduces input errors in environments where visual confirmation is not possible.

How to choose a dome switch PCB?

When selecting a dome switch PCB, consider the following factors:

- Actuation Force: Measured in grams, this defines how much pressure is needed. Lower force suits light-touch devices, while higher force is better for rugged environments.

- Dome Shape and Size: Round domes provide a softer feel, while four-leg domes give a firmer, centered click.

- Travel Distance: Short travel is faster; longer travel can feel more pronounced.

- Durability: Industrial devices may require millions of actuations.

- Environmental Resistance: For outdoor or harsh use, look for sealed designs.

- Mounting Method: PCB metal dome membrane switches can be integrated with adhesive films, dome arrays, or directly on the board.

- Electrical Characteristics: Ensure the dome’s contact resistance matches the circuit design.

By matching these parameters to your application, you can maximize both performance and lifespan.

How to extend PCB metal dome life?

Proper design and handling can greatly increase the service life of a metal dome switch:

- Choose Quality Domes: Use domes made from high-grade stainless steel with consistent spring characteristics.

- Avoid Excessive Force: Overloading can permanently deform the dome.

- Protect Against Contamination: Dust, moisture, or oils can affect contact performance.

- Use Stable Mounting: Ensure the dome stays centered and stable within its housing.

- Control Operating Environment: Avoid extreme heat or corrosive atmospheres.

In well-designed PCB dome switch assemblies, domes can function reliably for years without noticeable degradation.

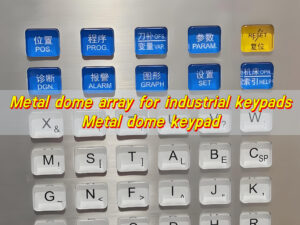

What is a dome switch keyboard?

Dome switch keyboard uses metal or rubber domes under each key. In the case of metal dome keyboards, the keys activate the domes directly over PCB contact pads.

Pressing a key pushes the dome, closing the circuit and producing tactile feedback. This type of keyboard is common in specialized control panels, medical equipment, and some compact consumer devices.

Because of the tactile metal dome switch mechanism, these keyboards are often preferred for precision input. They can be sealed for water and dust resistance, making them suitable for industrial or outdoor applications.

Where is a dome switch button used?

Dome switch button is used anywhere reliable, repeatable input is required. Typical applications include:

- Handheld communication devices

- Automotive dashboard controls

- Industrial machinery panels

- Medical diagnostic equipment

- Consumer electronics such as remote controls

- Security access panels

In each case, the metal dome PCB switch design provides durability, compact size, and a consistent user experience.

Conclusion:

Metal dome PCB switch delivers reliable tactile feedback, long life, and a compact design for a wide range of products. From a metal dome PCB membrane switch to a tactile metal dome switch or a complete dome switch keyboard, this technology ensures precise and consistent performance.

Best Technology specializes in high-quality PCB metal dome membrane switches tailored to your exact requirements, combining durability, responsiveness, and cost efficiency. For tailored solutions and technical support, contact sales@metal-domes.com