Membrane switch design guide provides key design principles, covering aspects such as structure, materials, graphics, process and testing. Common membrane switch types include flexible membrane switches, which have good insulation and heat resistance and are suitable for flat and curved surfaces; and rigid membrane switches, which are based on printed circuit boards, have stable processes and are easy to solder components.

What is a membrane switch?

Membrane switch is a low-profile electrical switch made up of flexible layers. It’s used to activate a circuit when pressure is applied to the top layer, completing the connection underneath.

Unlike mechanical switches, membrane switches don’t use metal contacts that press together. Instead, they rely on pressure pads printed with conductive ink or metal domes to complete the circuit. This makes them compact, reliable, and cost-effective.

They’re commonly used in medical devices, home appliances, industrial control panels, and other applications where space-saving and reliability are essential.

What types of membrane switches are there?

Membrane switches come in several designs, each offering different tactile feedback, visual appeal, and functional benefits.

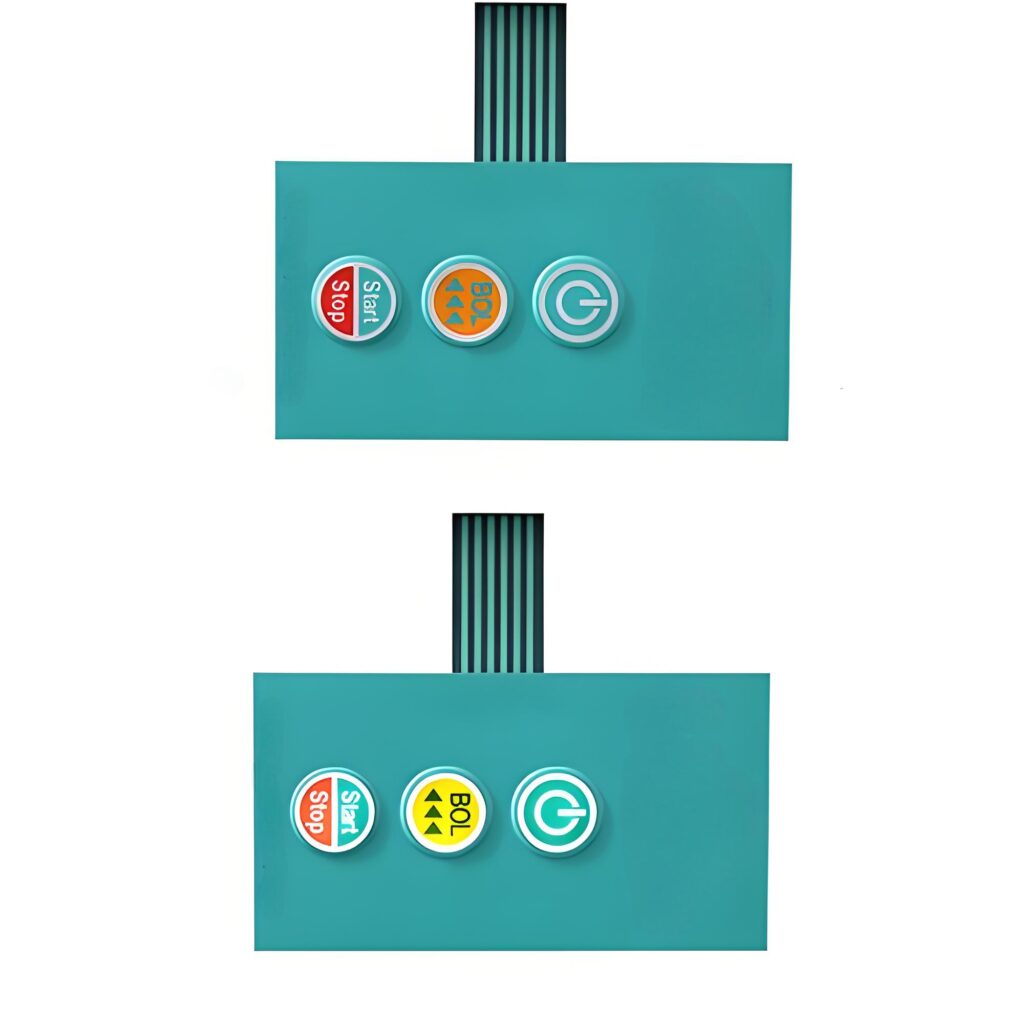

- 1. Tactile Membrane Switch

These use metal domes or polydomes beneath the top layer. When pressed, they create a noticeable snap—giving users physical feedback. They’re popular in medical and industrial settings where precision matters.

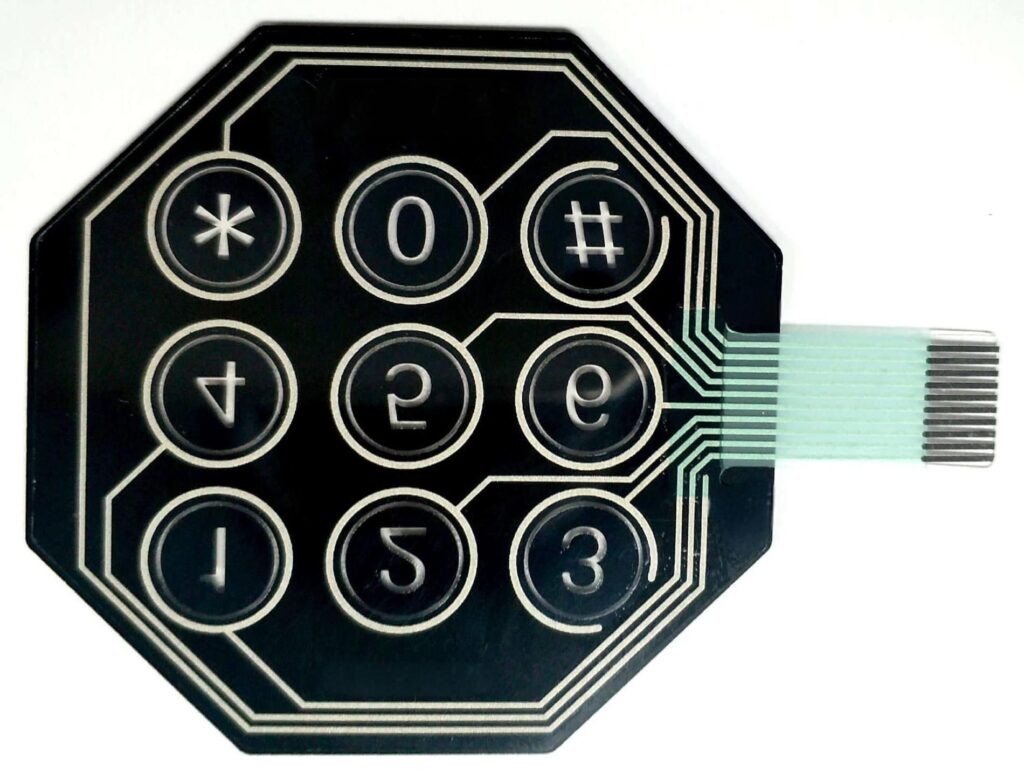

- 2. Non-Tactile Membrane Switch

No tactile feedback is felt when pressing. These switches often rely on visual or audible signals instead. They’re ideal for sleek devices where quiet operation is needed.

- 3. Backlit Membrane Switch

Add LEDs beneath the layers and you get a backlit version. These switches offer better visibility in low-light environments. A common choice for medical and nighttime applications.

- 4. Flexible Circuit Membrane Switch

These use a flexible printed circuit (FPC) instead of a rigid board. They’re extremely lightweight and bendable—perfect for curved or space-constrained surfaces.

- 5. Rigid PCB-Based Membrane Switch

Instead of flexible layers, this switch uses a rigid printed circuit board. It adds durability and supports complex electrical functions like capacitive touch and embedded chips.

How to design a membrane switch?

Designing a membrane switch is part engineering, part creativity. Layer thickness, dome shape, LED placement affects the final product’s performance.

- Start With the User Experience: How will the user interact with it? Do they need tactile feedback? Should the button light up? Will it face moisture or dust?

- Choose the Right Structure: Decide between tactile or non-tactile. Tactile switches require dome selection—metal dome or polydome.

- Integrate the Graphics Layer: The top layer, often called the overlay, displays printed icons or text. Choose materials like PET or polycarbonate, and make sure they withstand abrasion, UV, and chemicals.

- Plan for Lighting: Will you use light guide film (LGF)? Are you using colored or white light?

- Define Connector Type: Choose from ZIF, FPC, or male connectors based on your assembly needs.

What are common membrane switch design mistakes?

Membrane switch designs often fail due to small oversights. Avoiding these can save money, time, and headaches.

- Poor Dome Placement: If the metal dome isn’t centered over the contact point, the button won’t respond correctly.

- Ignoring Environmental Factors: Moisture, dust, or extreme temperatures can damage a poorly protected switch. Always plan for waterproofing (like sealing layers or gasket integration) if needed.

- Incorrect Overlay Design: Using poor materials or the wrong adhesive weakens durability. Always match your overlay to the device’s end-use environment.

- Inconsistent LED Spacing: Too many or too few LEDs, or incorrect placement, results in uneven lighting. Use light guide films to spread brightness evenly.

- Wrong Circuit Design: Overcomplicating the circuit or using traces that are too thin can lead to early failure.

What materials are used in membrane switches?

Choosing the right materials is critical to performance, feel, and lifespan.

- Top Layer (Graphic Overlay): Usually PET (polyester) or polycarbonate. PET offers excellent chemical resistance, while polycarbonate allows for sharper graphics.

- Spacer Layer: This layer separates the circuit and allows the button to return to its original state after being pressed. Commonly made of adhesive PET or double-sided adhesive.

- Dome Layer: If tactile feedback is needed, this layer holds the metal or polyester domes. Metal domes offer crisp feedback and longer life (up to 1 million cycles).

- Circuit Layer: Printed using conductive inks (like silver or carbon) on PET or polyimide film.

- Rear Adhesive: This secures the entire switch to the panel or device housing.

How to add LEDs to a membrane switch?

LED integration boosts both aesthetics and usability.

- Choose Your LED Type: Standard surface-mount LEDs are common. Some designs use side-firing LEDs with light guide films to spread light evenly across larger areas.

- Add a Light Guide Film (LGF): LGF channels light from the LED and distributes it across the panel. It ensures soft, even lighting instead of harsh points.

- Design for Power Management: LEDs draw power. Your circuit design should accommodate voltage and current requirements, especially in battery-powered devices.

- Decide LED Function: Is the LED always on, backlighting labels, or does it light up only when pressed?

What industries use membrane switches?

Membrane switch panels are used across many industries thanks to their compact size, reliability, and flexibility.

- Medical Equipment: In diagnostic tools, hospital beds, and infusion pumps, membrane switches offer sterile, wipe-clean surfaces and clear user interaction.

- Industrial Machinery: These switches control heavy equipment, CNC systems, and factory automation interfaces.

- Consumer Electronics: Microwaves, washing machines, and home security systems all use membrane switches for their smooth appearance and responsive feel.

- Military and Aerospace: Switches must endure vibration, altitude, and harsh elements.

- Transportation: Used in car dashboards, control panels, and marine devices.

Conclusion:

Membrane switches are the invisible interface behind many of today’s most reliable electronic devices. Whether you need a sleek keypad for medical equipment, a backlit control panel for industrial machines, or a flexible switch for consumer electronics. If you’re ready to start designing your next membrane switch panel or need expert advice, contact us at sales@metal-domes.com