In control systems, automation, and electronic design, a small choice can create a large impact. One of those choices is the decision between normally open vs normally closed contacts. At first glance, the distinction looks simple. In practice, it shapes safety, reliability, and system behavior under stress.

Engineers encounter this decision in switches, relays, sensors, flow controls, and safety circuits. It appears in schematics, wiring diagrams, and specifications. Yet confusion still happens, especially when systems fail or behave in unexpected ways.

What Is the Difference Between Normally Open and Normally Closed?

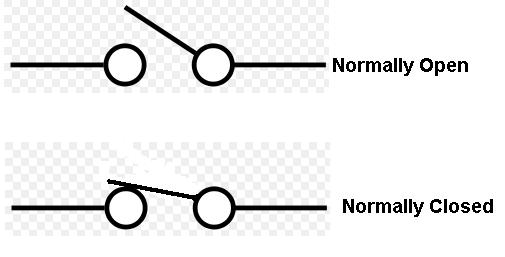

The terms “normally open” and “normally closed” describe the default state of a contact when no external force or power is applied. The word “normally” is the anchor. It refers to the rest state of the device.

A normally open contact does not allow current to flow in its default condition. The circuit remains open. When the switch is pressed, the relay is energized, or the sensor is triggered, the contact closes and current flows.

A normally closed contact behaves the opposite way. In its default condition, the circuit is complete. Current flows. When the switch is pressed or the device is activated, the contact opens and current stops.

This distinction matters because systems spend most of their life in the “normal” state. Engineers design around what happens during rest, not only during action.

Because of this, the choice between normally open vs normally closed affects standby power, fault detection, and system response when something goes wrong.

Is Normally Open Energized?

A normally open contact is not energized in its resting state. There is no electrical path. Current does not flow. The circuit waits.

Once an external action occurs, such as pressing a button or energizing a coil, the contact closes. At that moment, the circuit becomes active. Power flows. The load responds.

This behavior makes normally open contacts ideal for intentional actions. Examples include start buttons, momentary switches, and user-driven controls.

Engineers often prefer this logic because it prevents accidental activation. If power is lost or wiring breaks, the system stays inactive. That behavior feels intuitive.

However, it also means faults can remain hidden. A broken wire in a normally open circuit may look the same as an idle system. This trade-off becomes important in safety design.

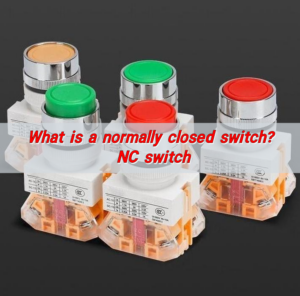

Does NC Mean NO Connection?

This is a common misunderstanding. NC does not mean “no connection.” In fact, it means the opposite.

Normally closed means the connection exists when the device is at rest. Current flows through the contact until an action interrupts it.

The confusion often comes from reading schematics too quickly. Engineers sometimes associate “closed” with inactivity. Electrically, closed means continuity. Open means interruption.

Understanding this clearly prevents wiring errors. It also helps during troubleshooting. When diagnosing faults, knowing which contacts should conduct in rest conditions saves time.

In control panels and industrial equipment, this clarity becomes critical. A single misinterpreted contact can reverse system logic.

Should a Flow Switch Be NO or NC?

Flow switches detect movement. They confirm presence rather than absence. Because of that, engineers often prefer normally closed configurations.

With a normally closed flow switch, current flows when fluid is present. If flow stops, the contact opens. The system detects the interruption immediately.

This design creates a natural fail-safe. If wiring breaks or power is lost, the system behaves as if flow has stopped. That response prompts attention.

In contrast, a normally open flow switch only closes when flow occurs. If a wire breaks, the system cannot distinguish between no flow and a fault.

For applications involving cooling, lubrication, or safety interlocks, this difference matters. Many engineers choose NC not because it is better, but because it communicates failure more clearly.

Is a Start Button NC or NO?

A start button is almost always normally open.

In its resting state, it does nothing. The circuit remains inactive. When the operator presses the button, the contact closes. The system starts.

This logic aligns with human expectation. Action creates motion. Release returns to rest.

Using a normally closed start button would invert that logic. The system would stop when pressed. That behavior can confuse operators and increase error risk.

However, stop buttons are usually normally closed. That choice ensures that a broken wire or power loss stops the system. This pairing creates balance.

Together, normally open start buttons and normally closed stop buttons form a predictable control scheme that engineers trust.

How to Tell If a Switch Is NC or NO?

There are several practical ways to identify contact type. The simplest is to check the datasheet. Manufacturers label terminals clearly.

If documentation is unavailable, a multimeter works well. With no force applied, test continuity between terminals. If continuity exists, the contact is normally closed. If not, it is normally open.

Visual markings also help. Many switches use symbols like NO, NC, or COM. Relays often include diagrams printed on the case.

In the field, observation matters. Ask what the system does at rest. Ask what happens when the switch is activated. Those behaviors reveal the answer.

Clear identification avoids incorrect assumptions. It also prevents rework later.

Can a Relay Be Both NO and NC?

Yes. Most control relays include both normally open and normally closed contacts.

A single relay coil can control multiple contact sets. When the coil is not energized, NC contacts conduct and NO contacts remain open. When energized, the states reverse.

This flexibility allows engineers to implement complex logic with fewer components. One relay can start one process while stopping another.

Because of this, relays are powerful tools in automation and control systems. They offer predictable behavior and electrical isolation.

Understanding how both contact types operate within the same device helps engineers design cleaner circuits.

Which Is Safer, NO or NC?

Safety depends on failure behavior. In many cases, normally closed is considered safer.

If a wire breaks in a normally closed circuit, the system detects a fault. The circuit opens. Action stops. Attention is triggered.

In a normally open circuit, a broken wire looks like inactivity. The system may not notice the problem.

For emergency stops, interlocks, and safety sensors, engineers often select normally closed contacts. This choice ensures that failure leads to a safe state.

However, safety is contextual. In some applications, unintended activation is the greater risk. There, normally open makes sense.

The safest choice is the one that fails in the most predictable and visible way.

When to Use NO vs NC?

Use normally open contacts when action should occur only after intentional input. Examples include start buttons, signal triggers, and user commands.

Use normally closed contacts when continuous monitoring matters. Examples include safety loops, flow detection, and fault signaling.

Consider how the system should behave during power loss. Consider how it should respond to broken wires. These questions guide the decision.

Engineers rarely choose based on habit alone. They choose based on system goals, risk tolerance, and maintenance strategy.

When applied thoughtfully, both contact types serve clear purposes.

Conclusion:

The difference between normally open vs normally closed is simple in definition, yet powerful in impact. One defines action through closure. The other defines safety through interruption.

For engineers, the choice shapes reliability, fault detection, and user experience. It influences how systems behave not only when everything works, but also when something fails.

Understanding this difference allows better decisions. It reduces confusion. It builds confidence in both design and troubleshooting.

If you are selecting switches, relays, or membrane key solutions and need guidance tailored to your application, our engineering-focused sales team is ready to help. Contact:sales@metal-domes.com