When sourcing custom peel & place metal dome solutions, choosing the right metal dome array manufacturers in Morocco directly impacts switch reliability, tactile consistency, and assembly efficiency. For buyers seeking stable quality, fast delivery, and engineering-level support, working with experienced Moroccan metal dome array manufacturers is key to long-term product success.

Are you facing these problems?

When working with local or international metal dome array suppliers in Morocco, customers often encounter the following core issues:

- Long prototyping cycles and repeated revisions, severely delaying new product launches

- Unstable dome force values and poor tactile consistency, affecting the end-user experience

- Insufficient peel & place accuracy, resulting in low SMT assembly yield

- Weak engineering support, unable to assist with dome selection and structural optimization

- Unfriendly to small batches, high MOQ, and high communication costs

- Unstable delivery times, frequently disrupting project plans

These problems essentially point to insufficient manufacturing capabilities, engineering experience, and delivery systems.

Full-Process Guarantee from Demand to Delivery: Our Solution

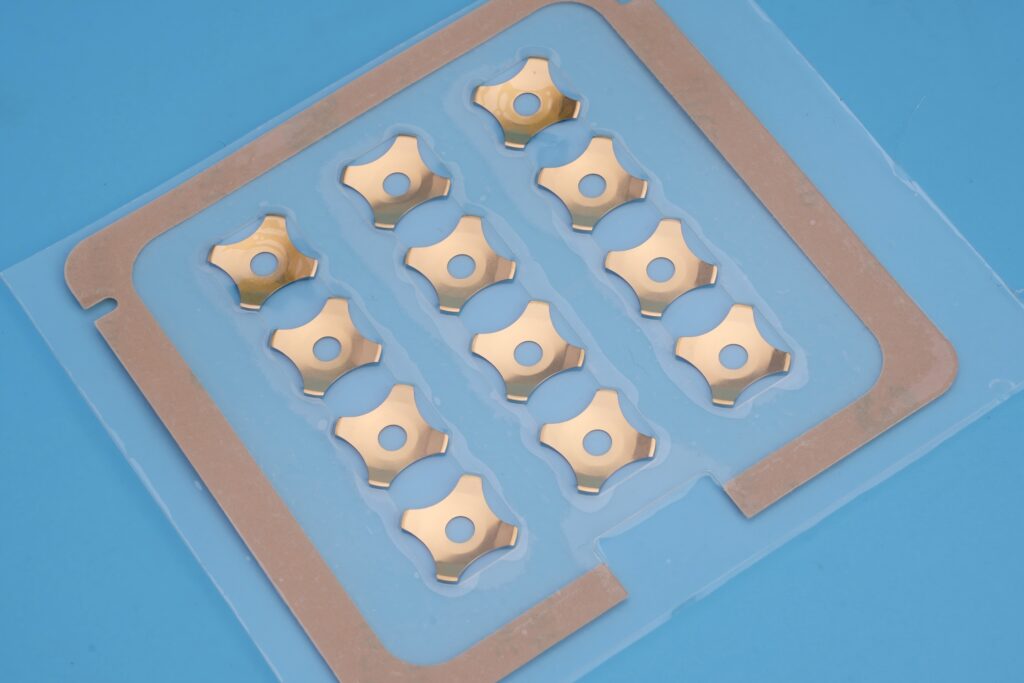

As a professional metal dome array manufacturer, EBest Circuit (Best Technology) is involved in customer needs from the initial stages of the project, covering the complete process from structural evaluation -> dome selection -> array design -> peel & place process -> mass production delivery.

We don’t just “produce metal dome arrays,” but help customers reduce trial-and-error costs, improve assembly efficiency, and ensure long-term stability. This is why more and more Moroccan customers choose to establish long-term partnerships with us.

Why Choose Us? EBest Circuit (Best Technology)’s Core Advantages

- Engineering First: 20+ years of experience in metal dome and dome array design, avoiding structural and tactile risks

- High-Consistency Manufacturing: Multiple controls on force value, rebound, and lifespan to ensure stability in every batch

- Fast Response Mechanism: Solutions to engineering problems provided within 48 hours

- Small Batch & Customization Friendly: Supports samples, trial production, and OEM/ODM

- International Standard Compliance: ISO9001, complete ROHS/REACH documentation available

Top 10 metal dome array manufacturers in Morocco

| Company Name | Process Capability | Core Advantage |

|---|---|---|

| EBest Circuit (Best Technology) | Custom metal dome array / peel & place / SMT compatible | Focus on dome array, engineering support, 2-3 day delivery, serves Morocco clients |

| Snaptron Inc. | Metal dome & tactile switch | Long brand history, higher price, slower delivery |

| Nicomatic | Human-machine interface components | European system, suitable for medical and industrial applications |

| Marquardt Group | Switch systems | Complete system, high MOQ |

| EAO AG | Industrial switches | Industrial grade, but not specialized in dome array |

| Shin-Etsu Group | Conductive materials | Strong in materials, does not offer custom array |

| Würth Elektronik | Electronic components | Channel-based, not an original dome manufacturer |

| Local EMS | Assembly service | Assembly only, no dome manufacturing capability |

| Trading Companies | Component sourcing | No engineering, no manufacturing control |

How to Choose a Morocco Metal Dome Array Manufacturer?

When choosing a Morocco metal dome array manufacturer, the criteria should not be limited to price or whether they can accept the order, but should focus on the following key capabilities:

- Does the manufacturer possess metal dome structural design and force engineering capabilities?

- Can they truly achieve custom peel & place metal dome arrays, rather than simply bonding?

- Do they consider SMT placement yield and positioning accuracy during the design phase?

- Can they provide complete technical parameters, lifespan data, and consistency verification?

- Do they support rapid prototyping + small-batch trial production + stable mass production?

- Do they have a mature quality control and engineering response mechanism?

Why is EBest Circuit (Best Technology) the best choice?

We don’t simply “produce based on drawings,” but instead conduct engineering evaluations starting from the dome diameter, thickness, actuation travel, and adhesive structure to ensure that the dome array has a stable feel and high placement success rate in the actual application environment of our Moroccan customers.

Core Pain Points of Metal Dome Array Manufacturers in Morocco

Common manufacturing pain points in the Moroccan market for metal dome array projects include:

- Failure to consider mass production during the design phase, leading to trial production failures

- Uneven dome force distribution, resulting in significant differences in feel between batches

- Peel & place misalignment, leading to high SMT rejection rates

- Short service life and insufficient long-term reliability

- When problems occur, manufacturers can only rework, unable to identify the root cause

How does EBest Circuit (Best Technology) systematically solve these problems?

- Force curve and structural feasibility assessments are completed before prototyping.

- High-precision molds and material control ensure force consistency.

- ±0.05mm alignment control is introduced during the peel & place stage, significantly improving placement yield.

- All dome arrays undergo millions of cycles of lifespan testing.

- The engineering team directly intervenes in problem analysis, correcting from the design and process source, rather than simply redoing the work.

This allows EBest Circuit (Best Technology) to fundamentally reduce project risks for our Moroccan customers.

How to analyze the production capabilities of a Morocco metal dome array manufacturer?

When evaluating the production capabilities of a metal dome array manufacturer, the following aspects should be considered:

- Does the manufacturer have independent metal dome forming capabilities?

- Does the manufacturer have automated dome array assembly processes?

- Does the manufacturer have specialized processes for peel & place?

- Does the manufacturer have a complete process inspection and final inspection mechanism?

- Can the manufacturer maintain stable delivery under multiple specifications and projects?

- Does the manufacturer possess the ability to combine large-scale and flexible production?

EBest Circuit (Best Technology)’s true strength is reflected in:

We have our own processes for metal dome stamping, forming, and array assembly, avoiding the instability caused by outsourcing. Through a combination of automation and precise manual control, we can meet the customized needs of our Moroccan customers while ensuring stable consistency during mass production – something that ordinary regional manufacturers struggle to achieve.

How to evaluate the delivery time of a Morocco metal dome array manufacturer?

Delivery time is not just about “speed,” but about whether it is controllable, predictable, and sustainable. The following dimensions should be considered:

- Can samples be delivered quickly and successfully on the first try?

- Does the manufacturer have the ability to handle urgent projects?

- Does the manufacturer have a stable production scheduling mechanism?

- Can the manufacturer quickly restart production after modifications?

- Can the manufacturer maintain stable delivery times in the long term?

EBest Circuit (Best Technology)’s delivery time advantage comes from its system, not from compressing processes:

Through a standardized dome specification library, mature array design templates, and parallel production line layout, we can complete sample delivery within 2-3 days. For our Moroccan customers, this means controllable project pace, faster time to market, and lower overall costs.

Morocco Metal Dome Array Manufacturer FAQ

- Q: Does customizing a dome array increase risk?

A: Professional engineering evaluation can significantly reduce risk; the key is the manufacturer’s experience.

- Q: Do you support small batch orders?

A: Yes, a well-designed manufacturing system is equally suitable for both samples and mass production.

- Q: How do you guarantee long-term consistency?

A: This requires a stable system of materials, processes, and testing.

- Q: How are problems handled?

A: A professional manufacturer should provide a rapid engineering response, not just product replacement.

Choosing the right metal dome array manufacturers in Morocco determines product reliability, cost, and speed to market—EBest Circuit (Best Technology) stands out among metal dome array manufacturers in Morocco by delivering engineering-driven quality, fast lead times, and true custom peel & place solutions.