Dome Array Manufacturers in Belgium increasingly rely on experienced overseas partners, and BEST Technology stands out as the best choice for Belgian customers seeking stable quality and cost efficiency. With nearly two decades of expertise in metal dome and dome array manufacturing, BEST Technology delivers high-precision dome arrays with tight dimensional control, ensuring consistent tactile feedback for industrial, medical, and consumer electronics applications.

Are you facing the following problems?

- Long prototyping cycles and frequent revisions: Initial dome array samples often require multiple rounds of verification, but some suppliers lack engineering support capabilities, leading to frequent rework on dimensions, tactile feel, and lifespan.

- Limited customization capabilities, unable to meet complex structures: For multi-key, irregularly arranged, or special trigger force requirements, many local manufacturers can only offer standard solutions and cannot provide in-depth customization.

- Poor consistency and insufficient batch stability: Inconsistent tactile feel from samples to mass production, large deviations in metal dome rebound force, seriously affecting the end product experience.

- Uncontrollable delivery times, affecting overall project progress: Unwillingness to accept small orders, long lead times for large orders, and opaque delivery schedules increase supply chain risks.

- High technical communication costs: Unclear explanations of engineering details and slow feedback lead to low project efficiency.

Full-Process Guarantee from Requirements to Delivery

As a professional dome array manufacturer, we don’t just provide “products,” but a complete solution covering everything from requirements assessment, structural design, prototyping and verification to mass production and delivery.

- During the requirements phase, our engineering team participates directly to confirm dome specifications, trigger force, lifespan, and application environment.

- During the design phase, we reduce failure rates through mature dome arrangement and conductive film matching solutions.

- During the prototyping phase, we quickly produce highly consistent samples, reducing repeated revisions.

- During the mass production phase, we use stable processes and standardized testing to ensure consistent performance in every batch.

This process is why more and more European customers, after evaluating Belgian dome array manufacturers, choose to cooperate with EBest Circuit (Best Technology) long-term.

Why choose us? EBest Circuit (Best Technology)’s core advantages

- 20+ years of experience in metal dome and dome array manufacturing: Deep understanding of industrial control, consumer electronics, medical, and automotive application scenarios, with precise control over structural and tactile requirements.

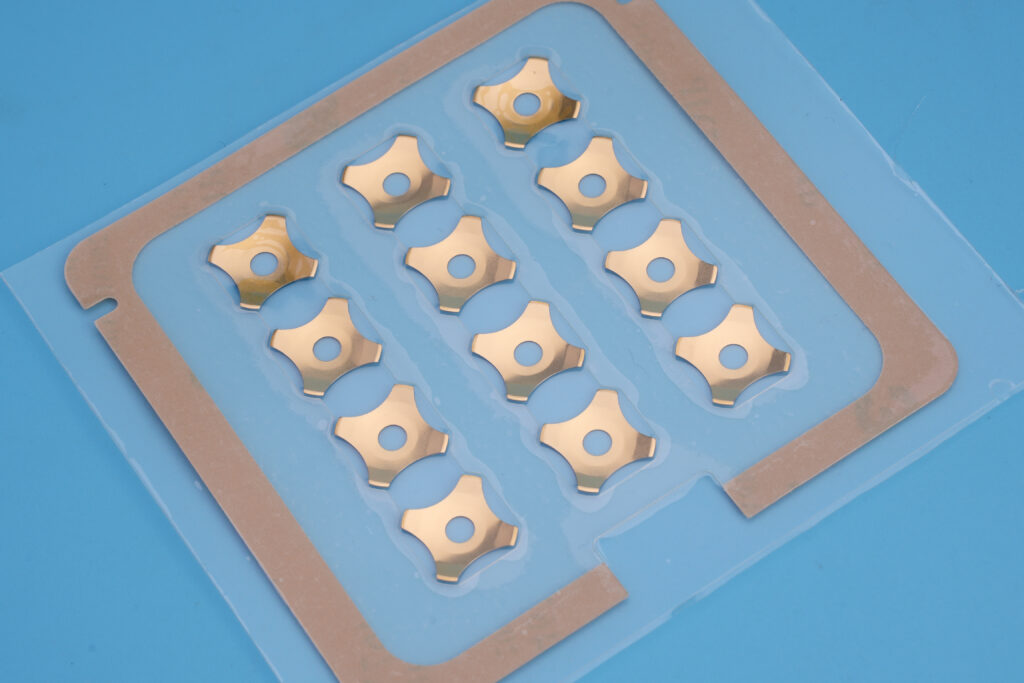

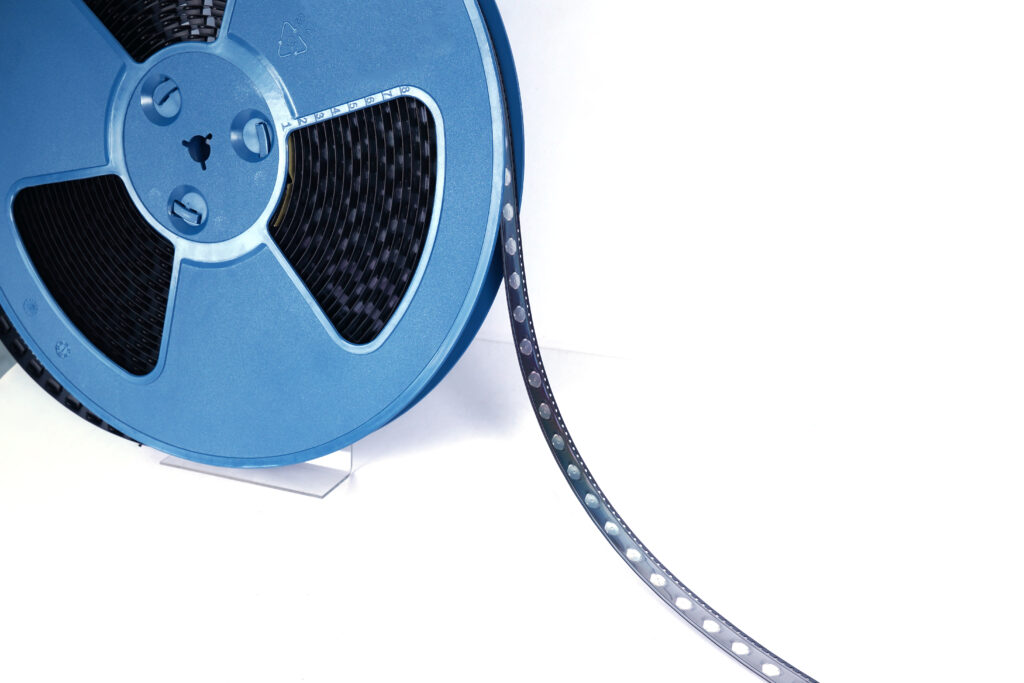

- Mature Tape & Reel Metal Dome solution: Supports high-speed SMT placement, with positioning accuracy controllable to ±0.05mm, significantly improving assembly efficiency.

- Engineering-driven, not sales-driven: Every project is evaluated for feasibility by the engineering team, avoiding design risks that may prevent mass production later.

- High consistency and ultra-long lifespan design: Through material selection and rebound force control, a stable lifespan of over 1,000,000 cycles can be achieved.

- Fast response and high level of cooperation:Â The technical team provides quick responses during the sample stage and communicates directly, which is ideal for the fast-paced projects of European clients.

Top 10 dome array manufacturers in Belgium

| Company Name | Business Scope / Process Capability | Specific Advantages |

|---|---|---|

| EBest Circuit (Best Technology) | Professional Metal Dome & Dome Array Design and Manufacturing (Supports Tape & Reel / SMT) | Engineering design support, strong mass production consistency, fast delivery |

| Quad Industries | Human-Machine Interface (HMI) & Control Panels / Flexible Sensors & Membrane Switches | Located in St. Niklaas, provides electronic control interface design and manufacturing services, can cooperate with dome array for HMI product development (local development advantage) |

| Eurocircuits | PCB Manufacturing and Assembly Services | Provides PCB production and assembly, can serve as a local partner for dome array and PCB integration |

| Eolane (Belgium) | PCB Design, Prototyping, and Assembly | International EMS (Electronic Manufacturing Services) provider, offers high-precision electronic assembly services in Belgium |

| Jabil (Belgium) | Global Electronic Manufacturing Services, including PCB Assembly and Complex Component Integration | Global EMS company with presence in Belgium, suitable for large-scale project integration |

| Sanmina (Belgium) | High-End Electronic Assembly and System-Level Integration | Provides extensive automated assembly capabilities, can be used to support dome array components |

| Celestica (Belgium) | Electronic Manufacturing Services and Engineering Support | Provides electronic manufacturing and assembly for multiple industries, including high-precision panels and interface components |

| Clicktouch Belgium | Input Device & Human-Machine Interface Design (Membrane Switches / Touch, etc.) | Years of experience in input device development and customization, suitable for cooperation with dome array |

| HTP Europe | Plastic Injection Molding and Precision Assembly | Provides manufacturing capabilities for product housings and mechanical support parts, can cooperate for dome array structural part production |

| Verco Electro Components | Electronic Component Distribution and Support | Provides component sourcing and technical advice, valuable as a parts supplier during the design phase |

How to Choose a Belgium Dome Array Manufacturer?

When choosing a Belgium dome array manufacturer, while price and delivery time are the obvious factors, the essential consideration is the maturity of their engineering system. You can assess this from the following dimensions:

- Do they possess true customization capabilities, not just assembly capabilities?

Many manufacturers can only “combine and arrange” existing dome specifications; they struggle when it comes to irregularly shaped key layouts or mixed trigger forces. EBest Circuit (Best Technology) has a complete database of dome specifications and mold resources, allowing for parameter-level customization based on trigger force, travel distance, and lifespan requirements, rather than simply using templates.

- Do they participate in the design phase, rather than only intervening after sample failure?

Most problems don’t arise during mass production, but stem from unreasonable structural design in the early stages. EBest Circuit (Best Technology)’s engineering team is involved before prototyping, evaluating dome arrangement, tolerances, and conductive film matching relationships, reducing the probability of failure from the source.

- Can they guarantee consistency between samples and mass production?

Samples may be feasible, but mass production can be uncontrollable – a common risk. EBest Circuit (Best Technology) uses the same materials, equipment, and processes for prototyping as for mass production, ensuring reproducible performance curves.

- Do they support SMT automated assembly solutions?

This directly determines subsequent assembly efficiency. EBest Circuit (Best Technology) provides a mature Tape & Reel Metal Dome solution that can be seamlessly integrated into SMT production lines.

Overall, EBest Circuit (Best Technology) doesn’t just meet “a few of these requirements,” but forms a closed loop in design, process, and delivery, making it a more reliable choice.

Core Pain Points of Belgium Dome Array Manufacturers

From a professional manufacturing perspective, common core pain points in Belgium dome array projects include:

- Low customization success rate and repeated trial and error

This is due to a lack of standardized engineering verification processes. EBest Circuit (Best Technology) uses a mature dome parameter model to complete pre-verification of trigger force, tolerance, and lifespan before prototyping, significantly reducing the number of trial and error cycles.

- Difficulty in controlling batch consistency

Manual or semi-automatic processes lead to inconsistent tactile feel. EBest Circuit (Best Technology) uses standardized stamping and bonding processes, and ensures stable rebound force for each batch through online inspection.

- Inability to accommodate both small-batch and mass production needs

Many manufacturers can only “choose one.” EBest Circuit (Best Technology) uses modular process design, allowing samples, small batches, and mass production to share the same technical path, avoiding switching costs.

- Low assembly efficiency impacts overall machine production capacity.

Traditional bulk metal domes are difficult to mount at high speeds. EBest Circuit (Best Technology)’s Tape & Reel Metal Domes can be directly used with high-speed pick-and-place equipment, significantly improving assembly efficiency.

These are not isolated problems, but systemic issues, and EBest Circuit (Best Technology)’s strength lies in its ability to provide systemic solutions.

How to analyze the production capacity of a Belgian dome array manufacturer?

Judging production capacity shouldn’t only focus on the number of machines, but rather on the following key points:

- Does it have stable metal dome forming capabilities?

- Does it have standardized dome array assembly and testing processes?

- Does it support multi-specification parallel production?

- Does it have lifespan, resilience, and reliability testing capabilities?

- Can it provide long-term stable supply, rather than just short-term delivery?

EBest Circuit (Best Technology)’s advantages in these areas are reflected in:

We not only possess complete dome forming and array assembly capabilities, but also ensure performance consistency across different specifications and batches through our ISO system and internal process standards.

How to evaluate the delivery time of a Belgian dome array manufacturer?

The core of delivery time is not “promising a few days,” but whether the conditions exist to fulfill that promise:

- Does it have reserves of raw materials for commonly used specifications?

- Does it have independent sampling and mass production scheduling?

- Can it handle urgent orders?

- Does it have mature packaging and logistics solutions?

EBest Circuit (Best Technology) can achieve fast delivery in 2-3 days, not by compressing processes, but because:

We maintain long-term stock of commonly used dome specifications and highly standardize the sampling process, combined with a mature Tape & Reel packaging solution, resulting in significantly higher production and delivery efficiency than the industry average.

Belgium Dome Array Manufacturer Frequently Asked Questions (FAQ)

- Q1: Will customizing the dome array significantly increase costs?

A: A well-designed solution can actually reduce rework and failure costs.

- Q2: Will the samples and mass-produced products have the same feel?

A: The key is process control, not the sample itself.

- Q3: Is it suitable for SMT automation?

A: High-speed placement can be achieved using a Tape & Reel solution.

- Q4: Can delivery times be guaranteed?

A: This requires evaluating whether the manufacturer has mature production scheduling and inventory management capabilities.