Looking for Germany metal dome switch supplier? This blog is mainly about a detailed selection guide to Germany metal dome switch supplier for helping you choose a reliable partner.

Custom Metal Dome Switch Supplier in Germany

Schurter

- Competence: Comprehensive tactile solutions from standard to highly customized designs.

Product Types:

- Panel-mount pushbutton switches: Support various operating forces and strokes, integrated with metal dome structures for clear click feedback.

- PCB through-hole tactile switches: Feature internal metal dome structures, suitable for compact spaces.

- Special customization: Supports customization of color, material, nameplate engraving, operating temperature, and terminal types.

Lead Time:

- Standard parts: Typically 2-4 weeks.

- Custom parts: 6-12 weeks (depending on mold development and small batch order quantities).

Advantages:

- Global certifications: UL, CSA, VDE, CE, and other international safety certifications, ideal for high-reliability industrial applications.

- Anti-interference technology: Excellent EMI resistance in industrial environments.

- Customer service: Dedicated Inside Sales team handles non-standard customization requests.

Fischer Panda

- Competence: Extreme environment adaptability and durability.

Product Types:

- Tamper-proof/vandal-resistant switches: Reinforced metal contact structures to prevent malicious tampering, designed for public facilities.

- Industrial pushbutton switches: Long-life, high-load tactile feedback solutions.

- Bypass switches: For fault isolation, with precision metal contacts inside.

Lead Time:

- Standard parts: Typically 1-3 weeks.

- Custom parts: 4-8 weeks (adjusted based on specific mold requirements).

Advantages:

- IP65/IP67 protection: Dustproof and waterproof designs, suitable for outdoor and harsh industrial environments.

- Pre-wired options: Switches with pre-terminated cables to reduce on-site installation time.

- Safety features: Physical locking mechanisms in some series to prevent accidental operation.

E-Switch

- Competence: Global supply chain support and diverse product offerings.

Product Types:

- Vandal-resistant series: Various shapes and lighting options (ring, dot, symbol), widely used in public transit and utilities.

- Rocker switches: Intuitive tactile feedback, commonly used for power control.

- Slide switches: Simple on/off control.

Lead Time:

- Standard parts: Typically 1-2 weeks.

- Custom parts: 3-6 weeks (fast response leveraging global supply chain).

Advantages:

- Comprehensive certification system: Complies with IEC, UL, CSA, and other international standards.

- Localized service: Offices in Germany ensure quick response to European customer needs.

- Pre-wired services: Multiple pre-wired versions available to reduce assembly costs for customers.

How to Choose A Reliable Germany Metal Dome Switch Supplier?

A Detailed Selection Guide to Germany Metal Dome Switch Supplier:

1. German Local Certifications and Industry Standard Compliance

- Prioritize suppliers holding German local certifications such as DIN (German Industrial Standards), TÜV (German Technical Inspection Association), and VDE (Electrical Safety Certification). This ensures compliance with electrical safety, environmental regulations (e.g., RoHS, REACH), and mandatory quality standards in Germany and the EU.

- Industry-Specific Certifications: For applications in automotive, medical, or industrial equipment sectors, verify if the supplier holds specialized certifications like ISO/TS 16949 (automotive) or ISO 13485 (medical devices) to mitigate compliance risks.

2. Technical Expertise and Customization Capabilities

- R&D and Design Support: German customers often require customized solutions (e.g., unique tactile feel, high/low-temperature resistance, dust/waterproof ratings). Suppliers should have an in-house R&D team capable of providing 3D modeling, force simulation (e.g., actuation force curve optimization), and rapid prototyping.

- Material and Process Innovation: Evaluate whether the supplier employs precision stamping, laser cutting, or electroplating processes, and uses high-performance metals (e.g., stainless steel, beryllium copper) or eco-friendly materials to ensure durability, conductivity, and environmental compliance.

3. Quality Control and Traceability

- End-to-End Quality Management: From raw material inspection (e.g., metal purity, thickness tolerance), production process control (e.g., automated assembly lines, in-line testing), to final product testing (e.g., life cycle testing, environmental adaptability tests), a robust quality management system (e.g., ISO 9001) is mandatory.

- Traceability System: German customers value supply chain transparency. Suppliers should provide batch traceability information (e.g., production date, operator, test data) to facilitate issue tracking and improvement.

4. Supply Chain Stability and Delivery Capability

- Localized Inventory and Logistics Network: Suppliers with warehouses in Germany or partnerships with local logistics providers support JIT (Just-In-Time) delivery, reducing transportation time and inventory costs. Assess capacity planning (e.g., peak order handling) and contingency plans (e.g., pandemic/supply chain disruption responses).

- Lead Time and Flexibility: German customers typically require clear delivery schedules. Suppliers must provide transparent production scheduling, real-time progress updates, and support for small-batch, multi-order flexibility to adapt to rapidly changing market demands.

5. After-Sales Service and Technical Support

- Localized Service Team: Suppliers with service centers in Germany or dedicated German-speaking technical support staff offer on-site installation guidance, troubleshooting, and timely responses (e.g., 24-hour initial response) to meet German efficiency expectations.

- Long-Term Collaboration and Maintenance: Provide lifecycle technical support (e.g., firmware updates, performance optimization) and spare parts supply, fostering long-term partnerships rather than one-off transactions.

6. Cost Efficiency and Value Engineering

- Total Cost Optimization: Beyond unit price, evaluate hidden costs like quality, lead time, and after-sales service. Use value engineering (e.g., material substitution, process simplification) to reduce costs without compromising performance.

- Transparent Pricing and Contract Terms: Provide detailed quotes (including material, processing, and logistics costs) with clear contract terms on warranty periods, breach liabilities, and compensation mechanisms to avoid disputes.

7. Environmental and Sustainability Practices

- Green Production and Circular Economy: German customers prioritize environmental responsibility. Suppliers should demonstrate practices in energy efficiency (e.g., renewable energy use), waste recycling (e.g., metal scrap reuse), and recyclable product design (e.g., modular structures).

- Carbon Footprint and ESG Reporting: Provide product carbon footprint data or ESG (Environmental, Social, Governance) reports to align with German customers’ sustainability requirements.

8. Customer References and Industry Reputation

- Localized Success Stories: Reference the supplier’s successful cases in the German market (e.g., supplying to renowned automotive brands or electronics firms) to validate performance and reliability in real-world applications.

- Industry Reputation and Certifications: Assess credibility and market standing through German industry associations (e.g., ZVEI), customer review platforms, or third-party rating agencies (e.g., Dun & Bradstreet).

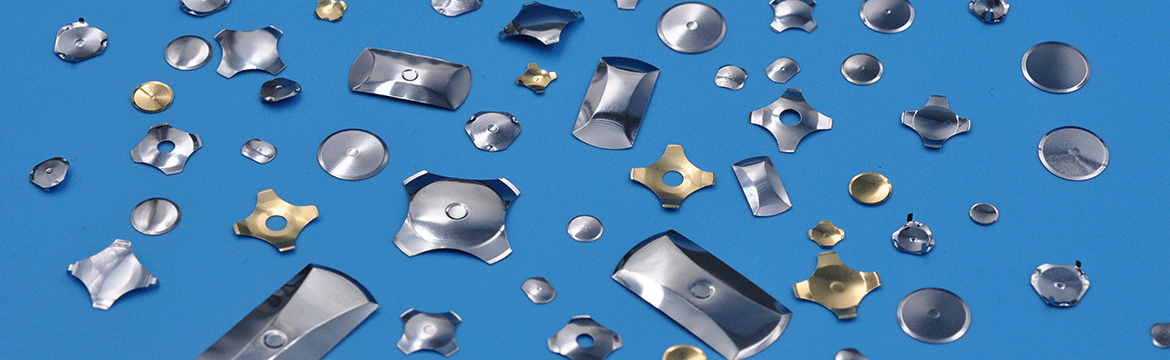

What Custom Options Can You Get From Germany Metal Dome Switch Supplier?

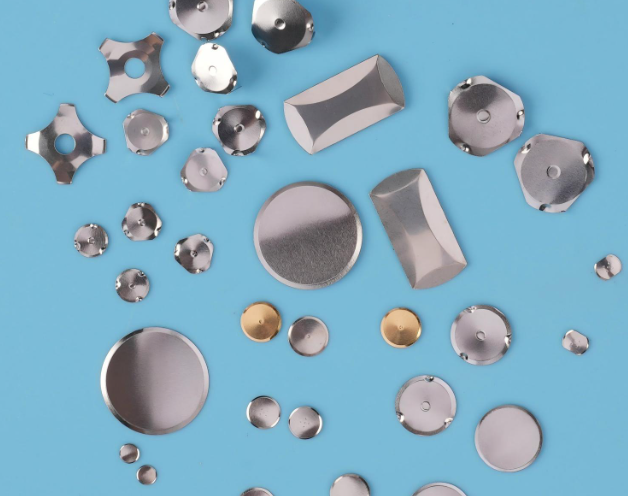

German metal dome suppliers usually support these custom options:

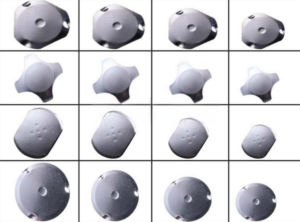

- Custom dome diameter selections

- Adjustable actuation forces

- Round, four-leg, triangle, and cross-leg dome structures

- Special surface coatings to reduce wear

- Tight tolerance on click ratio

- Dome sheets cut to exact layouts

- Integration with PET layers, adhesive layers, and spacer materials

- Embossed structures matched to the end-product enclosure

High MOQs Preventing Small Batches: Low MOQs from 50 Units for Custom Designs

Small-batch projects often face high minimum order quantity (MOQ) restrictions from large European factories. Best Technology offers flexible support for small-batch pilot production to address this. We understand that early prototyping may only require a small number of products. We offer MOQs as low as around 50 pieces, helping brands complete design validation without incurring excessive upfront costs.

Furthermore, the flexible MOQ policy allows our clients to test different tactile strengths, compare click feedback, or verify the durability of the dome before full-scale production. This facilitates a smooth transition from sample to mass production and effectively controls project costs.

More importantly, suppliers with low MOQs help startups and small device manufacturers maintain agility. Early prototyping is faster, redesign cycles are shorter, and deployment is easier. This attracts more global buyers to partner with us.

Unclear Lead Times Causing Delays: 99.2% On-Time Delivery Rate

When procuring metal dome switches, uncertainty in delivery dates is a common concern. Delays can slow product launches and put pressure on assembly schedules. Best Technology addresses this challenge with a rigorous scheduling system and dedicated personnel who track project lead times.

Our production plans typically accurately reflect material allocation, mold readiness, and molding line capacity. Best Technology boasts an on-time delivery rate of 99.2%. This exceptional performance attracts clients with stringent time constraints, such as medical device manufacturers and industrial equipment brands.

Furthermore, consistent delivery dates enhance supply continuity. Predictable deliveries instill confidence in the procurement team regarding long-term partnerships. They can schedule assembly lines more efficiently and reduce safety stock pressures.

Best Technology also supports planned forecasting projects, which further improve delivery performance. These projects match monthly demand with production capacity, maintaining stable supply even during peak seasons.

Harsh Environmental Challenges: -50°C to 120°C Range & IP67 Rating

Devices deployed outdoors or in harsh industrial sites need dome switches with proven durability. As a 19 years’ metal dome supplier, Best Technology often focus heavily on environmental reliability. Many domes pass fatigue testing, salt-spray exposure, and drop-shock evaluations. This ensures consistent tactile response even in demanding environments.

The typical operating range from -50°C to 120°C supports devices used in automotive dashboards, rugged controllers, and outdoor terminals. This wide temperature tolerance reflects strong material selection, tempering methods, and precise forming.

In addition, some dome switch structures reach IP67 performance when combined with the right sealing layers. This level of protection allows safe operation in moisture-rich environments. When integrated with sealed membrane switch assemblies, the domes maintain responsiveness without structural damage.

Why Choose Best Technology as Metal Dome Switch Supplier?

Reasons why choose Best Technology as your metal dome switch supplier:

- MOQ 50 Pieces for Custom Design, Zero Inventory Risk: Supports small-batch customization starting at 50 pieces, combined with free sample testing (FTIR/DSC verification ?98% consistency). Enables zero-risk quality validation, avoiding bulk procurement costs—ideal for startups or project validation phases.

- -50°C to 120°C Wide Temp Range & IP67 Protection: Industrial-grade reliability with extreme temperature resistance (-50°C to 120°C) and IP67 dust/waterproof certification. Solves core demands for stability in harsh industrial, medical, or outdoor environments, exceeding standard temperature ranges by 40%.

- 24-Hour Rapid Delivery, 12-Hour Emergency Response: Smart production scheduling ensures 48-hour delivery for regular orders and 12-hour turnaround for urgent orders, with 99.2% on-time delivery rate. Enables quick market response for scenarios like exhibition samples or urgent project replenishment.

- ?99.5% Batch-to-Sample Consistency, Industry-Leading Quality Control: SPC statistical process control and batch traceability ensure <0.5% performance variance between samples and bulk orders. ISO 9001-certified systems maintain defect rates below 0.3% (vs. industry 0.5% average), guaranteeing stable mass production quality.

- Transparent Pricing & 12%-18% Cost Reduction: Clear cost breakdowns (materials, labor, logistics) eliminate hidden fees and “low-price traps.” Clients report 12%-18% total cost savings compared to competitors, with transparent pricing applied even to 50-piece orders.

- 24-Hour Post-Sale Response & Free DFM Support: Free DFM (Design for Manufacturability) analysis for design modifications minimizes communication errors and rework costs. Post-sale issues receive initial response within 24 hours, ensuring seamless support for small-batch orders.

- 85% Repurchase Rate Backed by Global Success Cases: Serving 180+ countries with an 85% client repurchase rate. Proven success includes a medical client scaling from 20-piece sample testing to bulk production and an industrial client delivering exhibition samples in 36 hours—both highly rated for reliability.

Welcome to contact us to get a free metal dome switch sample: sales@metal-domes.com.