How Is the Price of a Metal Dome Calculated?

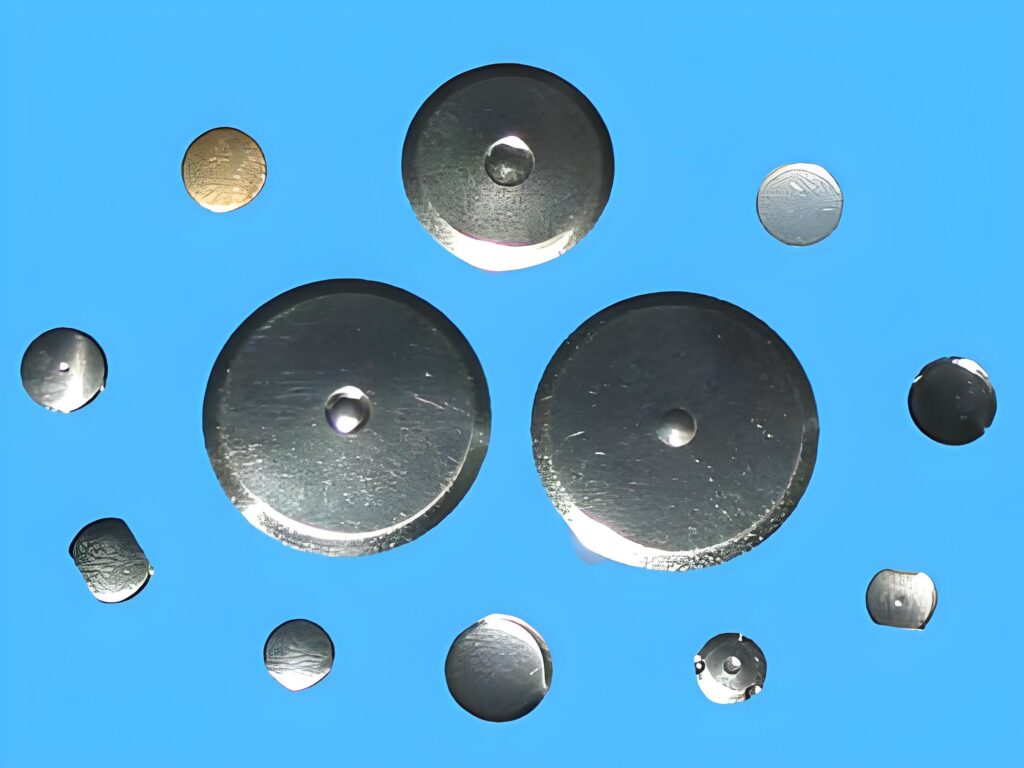

The primary factor is material. Most domes use stainless steel. Different grades offer different hardness, elasticity, and durability. A higher-grade stainless steel usually costs more because it maintains its shape longer.

Next comes size. A larger dome needs more material and a deeper forming stroke. Very tiny domes sometimes cost more as well because they require micro-precision tooling to maintain quality.

Shape influences cost too. Standard shapes such as round, triangle, oval, and cross are easy to produce. Custom or reinforced shapes require dedicated molds.

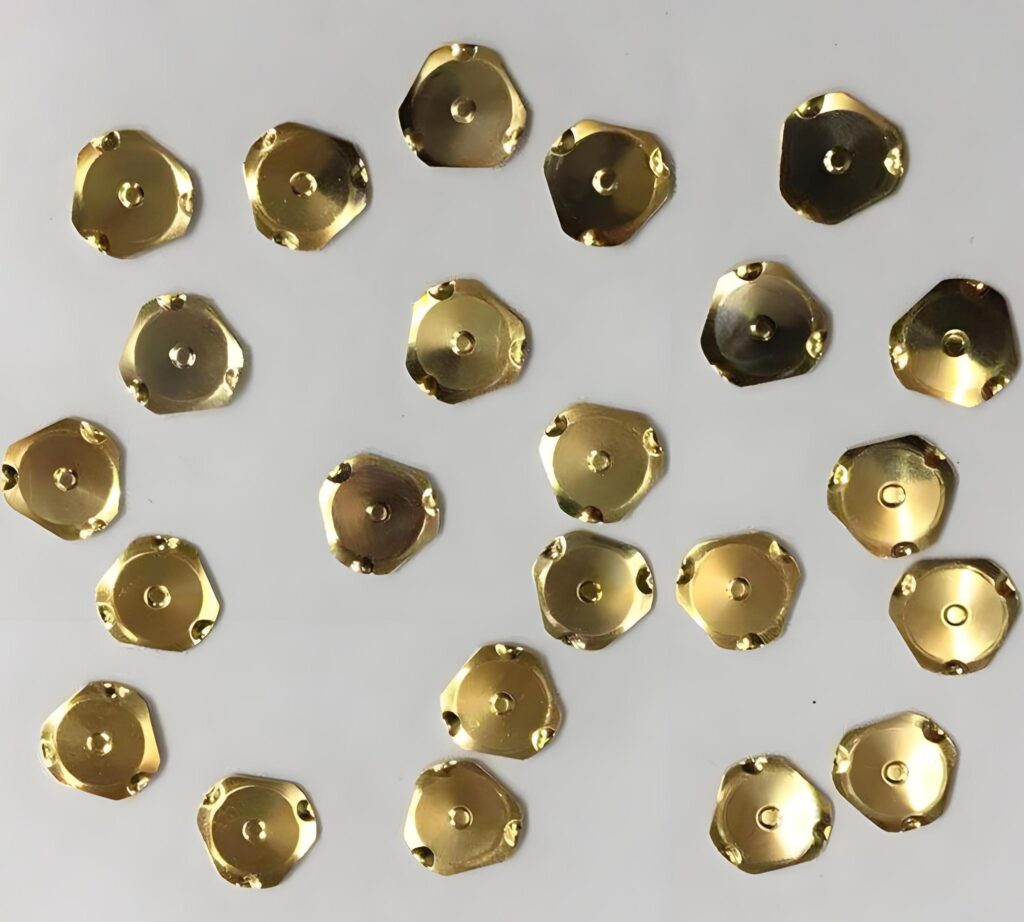

Surface treatment is another factor. Treatments like gold plating, nickel plating, or special coatings add cost but also improve corrosion resistance, stability, and conductivity. When a product works in harsh conditions, plating becomes essential for long-term reliability.

Packaging should not be ignored. Bulk packaging is the cheapest. But when you use tape-and-reel for automated lines, cost increases slightly because the packaging process is more advanced.

Even with all these variables, metal domes remain one of the most cost-effective tactile components in electronics. Their price is small. Their impact on user experience is huge.

How Do I Determine the Lifespan of a Metal Dome?

Lifespan is a key indicator of quality. When you want to evaluate the durability of a metal dome, you should look at the cycling test value. This number comes from automated equipment that presses the dome repeatedly under controlled conditions.

A typical high-quality dome can reach 200,000 to 1,000,000 cycles. Some reinforced models can even go higher. If a dome retains its feel after hundreds of thousands of presses, it is reliable enough for long-term use.

The structure of the dome influences lifespan. A higher dome height provides more space for elastic deformation. This gives the dome a deeper stroke and a longer life.

Environmental conditions also matter. High heat, high humidity, or constant vibration can change the mechanical properties over time. Gold or nickel plating protects the steel surface and maintains stable performance.

The adhesive layer and the top film in a dome array also influence lifespan. A high-quality adhesive keeps the dome centered and reduces misalignment during repeated use. The top film spreads the load evenly and helps prevent premature stress.

How Many Presses Does a Metal Dome Last?

Most metal domes last between:

- 200,000 presses (entry level)

- 500,000 presses (standard quality)

- 1,000,000+ presses (premium domes)

- Several million presses (reinforced designs under ideal conditions)

For consumer devices like remote controls, medical handheld tools, and smart locks, a million presses is far more than expected.

Industrial devices may have heavy daily usage. For example, a factory control panel may have keys pressed continuously for years. In such cases, choosing a high-durability dome becomes essential.

The “press life” also depends on how clean the operating environment is. Dust, oil, moisture, and vibration influence the longevity.

What Factors Affect the Feel and Sound of a Metal Dome?

Several factors shape the “touch personality” of a metal dome.

- The first is force value. Every dome has its own actuation force. A higher force makes the click feel stronger. A lighter force feels smooth and quick.

- Shape affects the tactile journey as well. Round domes feel balanced and clean. Triangle domes deliver a sharper snap. Cross domes feel soft yet controlled.

- Surface height is another element. A higher dome provides a deeper stroke and a louder click. A lower dome gives a soft, quiet touch.

- The sound also depends on the PCB or membrane under the dome. A stiff surface reflects sound and makes the click sharper. A softer surface absorbs some vibration and makes the click quieter.

- Coatings such as nickel or gold influence feel too. Nickel tends to generate a bright click. Gold feels smooth and stable. The coating also protects the dome, which indirectly helps maintain long-term tactile consistency.

When these factors blend perfectly, the result is a metal dome with a satisfying feel that users love.

Do BEST Technology’s Metal Domes Have Quality Certifications?

Yes. BEST Technology follows strict quality systems to ensure stable performance. The metal domes meet RoHS requirements and go through multiple internal tests such as:

- Force stability testing

- Lifespan cycling testing

- Temperature and humidity testing

- Residual force analysis

- Material inspection

- Dimensional accuracy checks

The company also follows ISO-based manufacturing systems. Each production batch has traceability. This means if you ever need test data, you can get it quickly.

How Is the “Click” Feel of a Metal Dome Achieved?

The click feel comes from controlled tension inside the dome. When you press the dome, it collapses at a precise point. The steel stores energy during the deformation. When the press is released, the stored energy returns and makes the dome spring back to its original shape.

That sudden release of energy produces the characteristic snap. It feels crisp. It feels decisive. It feels clean. This sensation is what makes metal domes superior to rubber keys when users want fast feedback. Several structural details work together to create this click.

The dome curvature defines how the steel bends. A deeper curvature usually creates a sharper click. A shallow curvature gives a gentler response.

The material hardness determines how quickly the dome transitions from stable to collapsed. A harder material makes the click brighter. A softer material makes the click more rounded.

The diameter-to-height ratio also plays a role. A higher dome generates more stored energy and a stronger tactile snap. A lower dome creates a smooth curve with less energy release.

The press point matters too. Pressing the center gives the purest click. Pressing the edge spreads the stress unevenly and slightly reduces the sharpness.

BEST Technology uses high-precision forming tools that maintain force stability. This ensures the click remains clean and repeatable.

How Can I Ensure a Clear “Click” Sound from a Metal Dome?

If you want a clean, bright click, you should consider several design elements.

- First, choose a dome with an appropriate height. A higher dome produces a louder and clearer sound.

- Next, consider surface plating. Nickel plating tends to produce a bright and crisp click. Gold produces a smooth sound that is slightly softer but very stable over time.

- Another factor is the surface under the dome. A rigid PCB or a hard plastic surface reflects sound. A soft adhesive layer or a silicone layer absorbs it.

- The actuation force also influences sound. Higher force usually means a louder and more decisive acoustic snap.

- Even the mounting method affects click clarity. In dome array applications, the adhesive film should be taut enough to prevent damping. If the film becomes too soft, the sound may weaken.

By following these steps, you can achieve a powerful click effect.

What Factors Are Most Important to Consider When Choosing a Metal Dome?

Choosing the right dome is not difficult when you know what to look for. Several factors deserve your attention.

- 1. Actuation force

This defines how much pressure the user needs. It shapes the emotional experience.

- 2. Size and shape

These influence the feel and the stroke. They also affect PCB layout or membrane key design.

- 3. Surface plating

Gold or nickel can improve stability and help meet environmental demands.

- 4. Environmental conditions

If your device works outdoors, in vehicles, in medical rooms, or in high-humidity areas, choose a dome that offers enhanced durability.

- 5. Lifespan rating

Match the dome to daily usage. A keypad in a factory needs a higher rating than a home appliance.

- 6. Acoustic preference

Some products want a soft click. Others want a sharp sound. Choose height and material accordingly.

- 7. Mounting method

Bulk domes allow flexible positioning. Dome arrays offer fast assembly and better dust protection.

- 8. Tolerance requirements

If your button structure has strict height control, make sure the dome meets dimensional accuracy needs.

Finally, consider the supplier. A reliable supplier ensures stable batches, fast delivery, and consistent quality. BEST Technology provides all those advantages backed by nearly 20 years of experience.

Will Custom-Made Metal Domes of a Specific Specification Be Very Expensive?

Many people worry that custom domes are costly. They are usually not. Custom domes often require a new mold, but the mold cost is generally reasonable. It is a one-time expense. After that, the unit cost remains stable.

Custom domes can help you shape a unique tactile identity. If you want a softer force, a louder click, or a specific height, customization helps you reach your goal.

Custom domes are useful in projects with special housing structures. They also help when space is limited or when environmental demands are strict.

In most cases, the benefits outweigh the cost. Custom domes help create a stronger user experience and bring your product closer to perfection.

At BEST Technology, we try to minimize the cost of custom tools. We build tools in-house. This reduces price. It also speeds up delivery.

Conclusion:

Metal domes may be small, but they influence every part of the user experience. Their price depends on size, shape, force, plating, volume, and packaging. Their lifespan reaches millions of presses when designed well. BEST Technology supports these needs with certified quality, strong engineering, and dependable production.

For questions, samples, or custom designs, feel free to reach out anytime. Email: sales@metal-domes.com